Pulsation vacuum sterilizer water cooling device and cooling method

A technology of water cooling device and sterilizer, which is applied in the direction of water supply device, sanitary equipment for toilet, heating, etc. It can solve the problems of damaging the external drainage pipe, affecting the use environment, and scalding the operator, so as to protect the operator and improve Cooling efficiency, the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically described below in conjunction with the accompanying drawings.

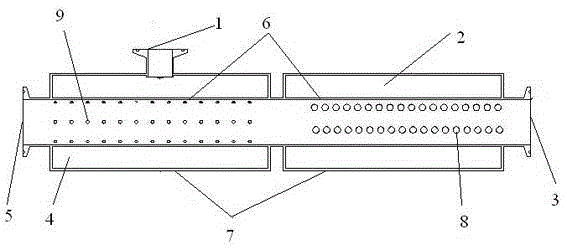

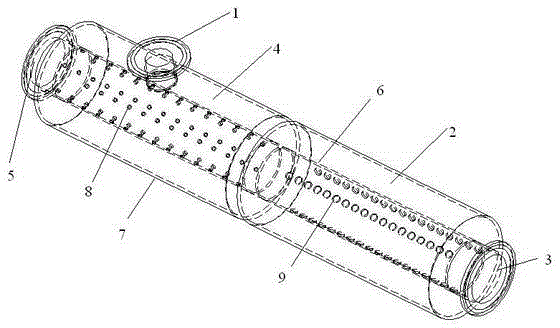

[0018] Such as figure 1 As shown, the water cooling device of the pulsating vacuum sterilizer includes: water inlet 1, steam decompression chamber 2, steam inlet 3, cooling mixing chamber 4, outlet 5, inner pipe 6, outer pipe 7, and pipe holes in the steam decompression chamber 8 and the pipe hole 9 in the cooling and mixing chamber, the discharge steam port of the sterilizer is connected to the steam inlet 3, the steam inlet 3 is located at one end of the opening of the inner pipe 6, and the other end of the opening of the inner pipe 6 is connected to the cooling water discharge pipe, which is located outside the cooling and mixing chamber 4 The upper middle end of the outer pipe 7 is provided with a water inlet 1, and it is also characterized in that the inner pipe 6 is distributed with a number of uniformly sized steam decompression chamber pipe holes 8 and coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com