Flexible temperature differential power generation micro-unit structure

A thermoelectric power generation, micro-unit technology, applied in electrical components, generators/motors, circuits, etc., can solve the problems of thermoelectric power generation unit failure, poor mechanical properties, easy fracture of alloy materials, etc., and achieve the effect of avoiding failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

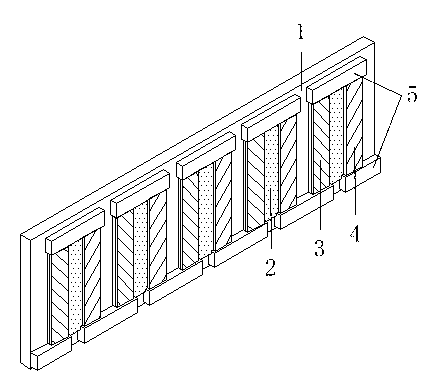

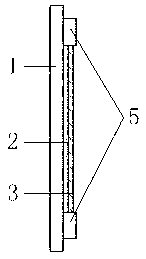

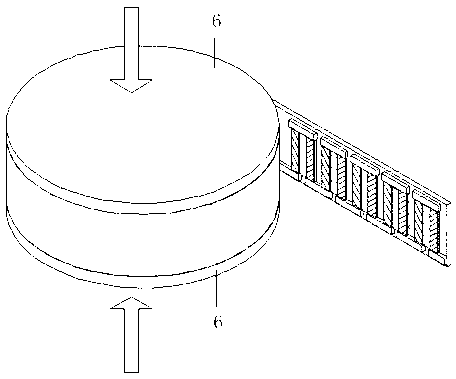

[0024] Such as figure 1 , figure 2 As shown, the present invention deposits a plurality of insulating hard films ( figure 1 There are 5 in the middle), and on both sides of each insulating hard film 2, there are a P-type thin-film thermoelectric arm 3 and an N-type thin-film thermoelectric arm 4 parallel to each other and equal in length and thickness. Each pair of P-type thin-film thermoelectric arms One end of the arm 3 and the N-type thin film thermoelectric arm 4 is connected with a conductive silver glue wire 5, and the other end of the P-type thin film thermoelectric arm 3 is connected with the other end of the adjacent N-type thin film thermoelectric arm 4 with a conductive silver glue wire 5, The other end of the N-type thin-film thermoelectric arm 3 is connected to the other end of the adjacent next P-type thin-film thermoelectric arm 4 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com