A kind of manufacturing method of lithium-ion battery anode sheet

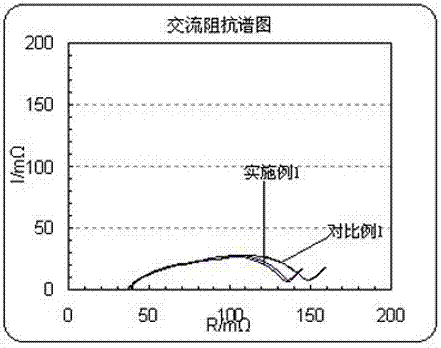

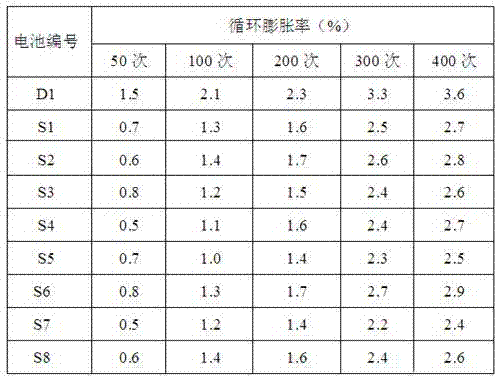

A technology of lithium-ion batteries and manufacturing methods, which is applied in the field of lithium-ion battery anode production, can solve the problems of easy demoulding of anode sheets, affecting battery efficiency, poor low-temperature performance of lithium-ion batteries, etc. Effects of reduction, flexibility improvement, and internal resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, a method for making an anode sheet of a lithium-ion battery provided in this embodiment includes the following steps: Step 1, preparation of anode slurry: anode active material natural graphite, aqueous thickener sodium carboxymethyl cellulose The water-based adhesive styrene-butadiene latex and superconducting carbon are added into water according to the mass ratio of 96:1:1:2, and the anode slurry is prepared after being stirred evenly.

[0026] Step 2, fabrication of anode sheet: uniformly coat the anode slurry prepared in step 1 on the anode current collector copper foil with a coating thickness of 100um, and then dry in a drying oven at 100°C to prepare an anode sheet.

[0027] Step 3, post-processing of the anode sheet: place the anode sheet prepared in step 2 in a nitrogen environment at 300°C for 30 minutes of secondary baking and softening treatment, and then complete the production of the anode sheet after cold pressing and slitting.

Embodiment 2

[0028] Embodiment 2, the manufacturing method of a kind of anode sheet of lithium ion battery provided in this embodiment, comprises the following steps: Step 1, the preparation of anode slurry: anode active material artificial graphite, aqueous thickener lithium carboxymethyl cellulose 1. Water-based adhesive pure acrylic latex and acetylene black are added into water according to the mass ratio of 92:2:5:1, and the anode slurry is obtained after stirring evenly.

[0029] Step 2, fabrication of anode sheet: uniformly coat the anode slurry prepared in step 1 on the copper foil of the anode current collector with a coating thickness of 200um, and then dry it in a drying oven at 110°C to prepare the anode sheet.

[0030] Step 3, post-processing of the anode sheet: place the anode sheet prepared in step 2 in a nitrogen environment at 250°C for 40 minutes of secondary baking and softening treatment, and then complete the production of the anode sheet after cold pressing and slittin...

Embodiment 3

[0031] Embodiment 3, a method for manufacturing an anode sheet of a lithium ion battery provided in this embodiment includes the following steps: Step 1, preparation of anode slurry: anode active material silicon-carbon alloy, water-based thickener carboxymethyl cellulose Potassium, water-based adhesive styrene-acrylic latex and carbon nanotubes are added into water according to the mass ratio of 94:1.5:3:1.5, and the anode slurry is prepared after being stirred evenly.

[0032] Step 2, fabrication of anode sheet: uniformly coat the anode slurry prepared in step 1 on the copper foil of the anode current collector with a coating thickness of 50um, and then dry it in a drying oven at 90°C to prepare the anode sheet.

[0033] Step 3, post-processing of the anode sheet: place the anode sheet prepared in step 2 in a nitrogen environment at 350°C for 50 minutes of secondary baking and softening treatment, and then complete the production of the anode sheet after cold pressing and sli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com