Mainboard used for radiator and machining method thereof

A processing method and radiator technology, which are applied in the field of improving the motherboard for radiators and its processing, can solve the problems of low qualification rate of one-time welding between the motherboard and the tube, affecting the reliability, stability and vibration resistance of the product, and cracking at the connection between the motherboard and the tube and other problems, to achieve the effect of shortening the production cycle, improving the welding quality, and increasing the welding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

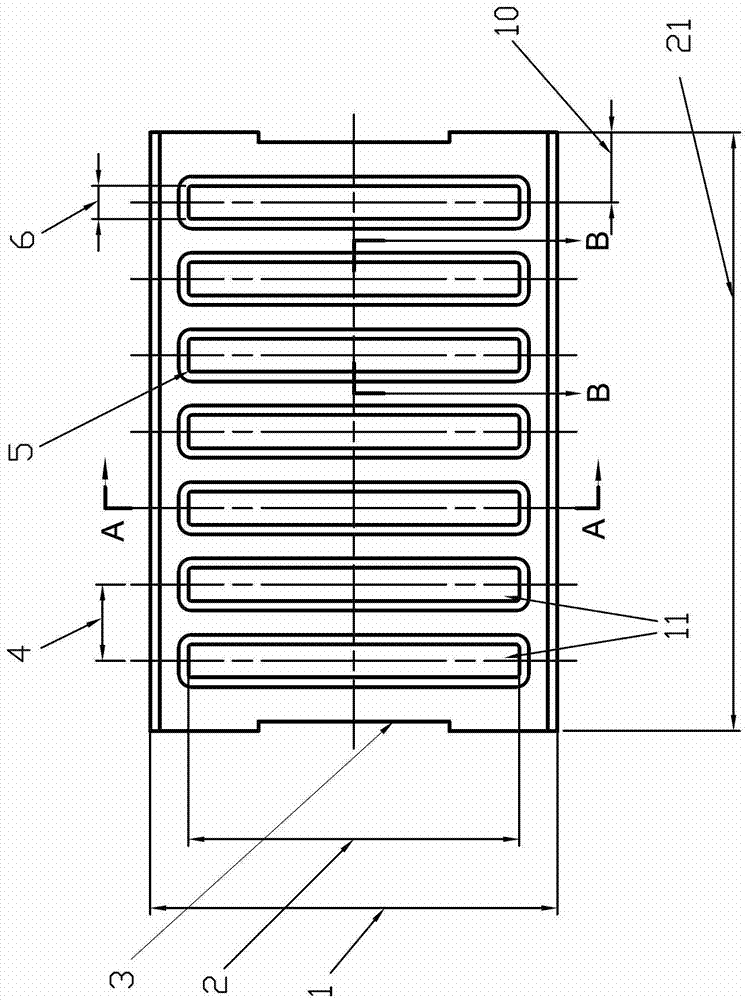

[0027] refer to figure 1 , figure 2 and image 3 , the structure of the mainboard for the existing heat sink. Its defects have been described above, and will not be repeated here.

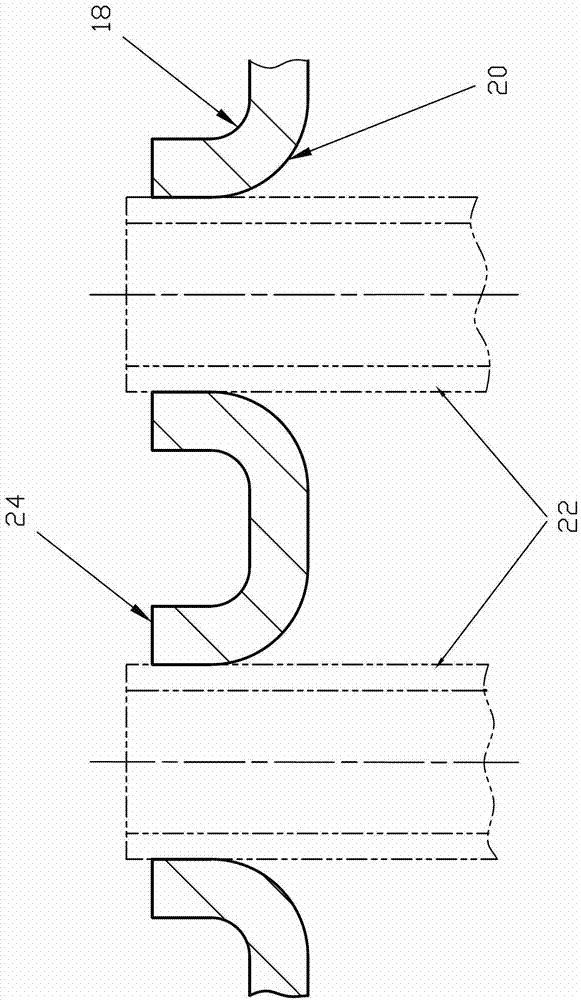

[0028] refer to Figure 4 and Figure 5 , a mainboard for a heat sink of the present invention, the mainboard body is in a rectangular structure, and the mainboard material is an aluminum composite material. There are a plurality of rectangular slots 11 on it, each of the slots 11 has a flange 25 formed by extrusion, the direction of the flange 25 is opposite to the bending direction of the main board, and the thickness of the flange 25 is close to 1% of the thickness of the main board. / 2.

[0029] refer to Figure 5 and Figure 6 , the present invention makes full use of the plastic deformation of the main board material to increase the flange height 10, which is more than doubled than that of the prior art, and then the welding area of the cooling pipe 22 and the main board is more th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com