A flooded chiller

A chiller, flooded technology, applied in refrigerators, refrigeration components, compressors, etc., can solve the problems of many fault points, many connection points, and high manufacturing costs, and achieve convenient maintenance, solve system blockage, and refrigeration effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

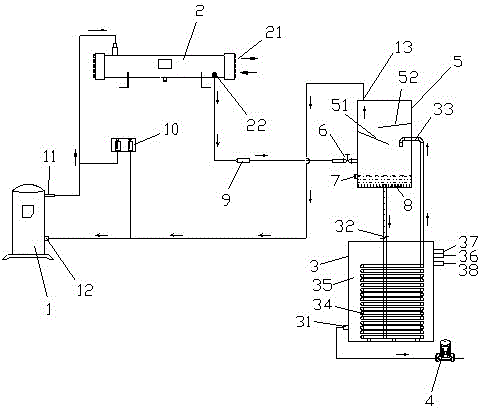

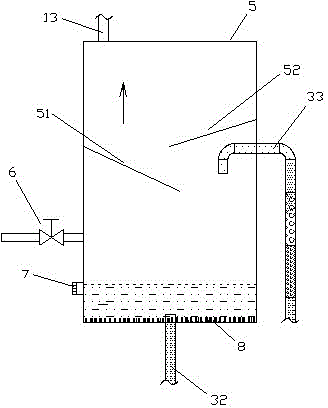

[0016] refer to figure 1 , figure 2 , a flooded water chiller of the present invention, comprising a gas compressor 1, a condenser 2 connected to the gas outlet 11 of the gas compressor 1, an outlet 22 of the condenser 2 and an inlet 12 of the gas compressor 1 The connected heat exchanger 3, the end of the condenser 2 is provided with a cooling water inlet and outlet 21, the bottom water outlet 31 of the heat exchanger 3 is connected with a water pump 4, and the outlet 22 of the condenser 2 and the gas compressor The inlet end 12 of 1 is communicated with heat exchanger 3 respectively and also communicates with a vapor-liquid separation device 5 in the middle, and described vapor-liquid separation device 5 is connected with the outlet 22 of condenser 2 and the inlet end of gas compressor 1 respectively. 12. The liquid inlet 32 and the gas outlet 33 of the heat exchanger 3 are connected to each other, and a throttling device 6 is provided between the outlet 22 of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com