Water heating boiler

A technology for hot water boilers and boilers, which is applied in the field of boilers, can solve the problems of increased frictional resistance of water circulation, reduced pressure head, scaling, etc., and achieves the effects of avoiding boiler vaporization, being difficult to scale, and reducing scaling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

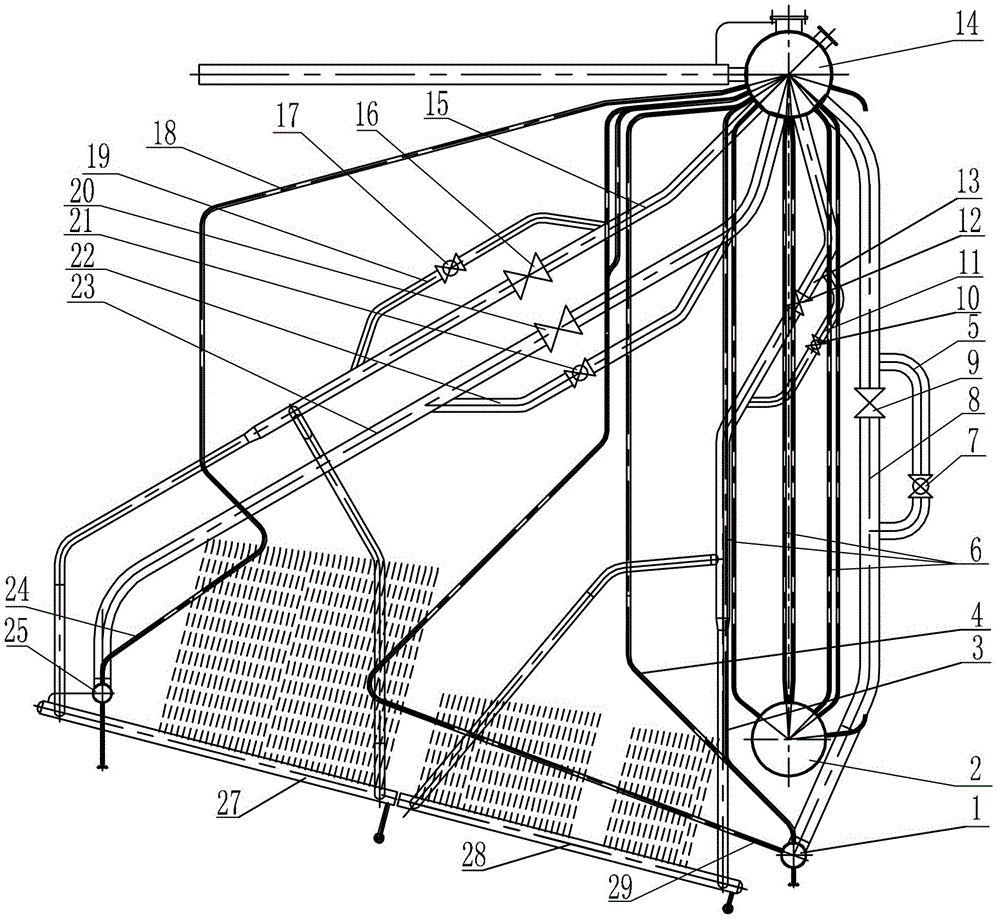

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, a hot water boiler in this embodiment includes an upper drum 14, a lower drum 2, a first lower header 1, a second lower header 28, a third lower header 27, a fourth lower header Box 25, convection tube bundle 6, front wall water cooling wall descending pipe 23, first side wall water cooling wall descending pipe 15, second side wall water cooling wall descending pipe 13, rear wall water cooling wall descending pipe 8, first ascending pipe 3, the second Two ascending pipes 4, the third ascending pipe 29 and the fourth ascending pipe 24, the upper drum 14 and the lower drum 2 are communicated by the convection tube bundle 6, and the two ends of the rear wall water wall descending pipe 8 are connected with the upper drum 14 and the second ascending pipe respectively. The lower header 1 is connected, the two ends of the first riser 3 are respectively connected with the upper drum 14 and the first lo...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 The present embodiment will be described. The first control valve 16 in the present embodiment is a quick opening characteristic control valve. This setting is used for two-position control, which is convenient for the chain control of control valves and pipeline pumps. Others are the same as the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 The present embodiment will be described. The second control valve 20 in the present embodiment is a quick opening characteristic control valve. This setting is used for two-position control, which is convenient for the chain control of control valves and pipeline pumps. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com