An orifice blowout preventer

A blowout preventer and orifice technology, which is used in wellbore/well components, earthwork drilling, sealing/packing, etc. The problem is to prevent the orifice from spraying water outward, the structure is simple, and the reliability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

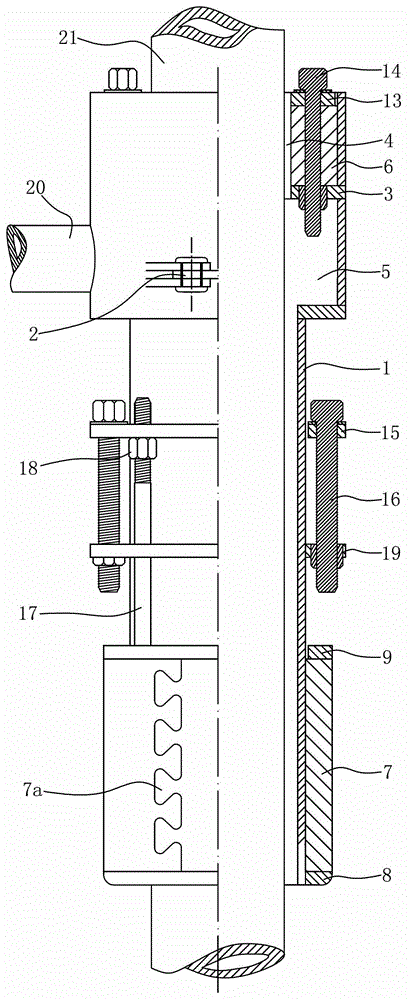

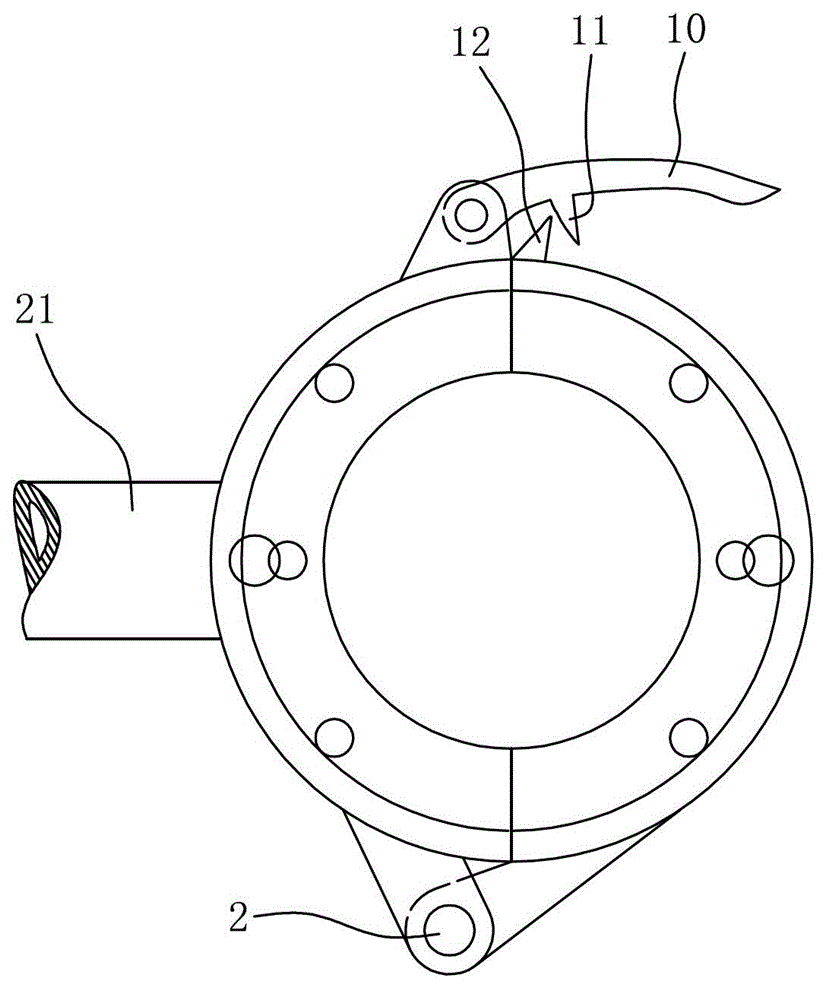

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0017] Such as figure 1 , figure 2 As shown, two symmetrically arranged half bodies encircle to form a cylindrical structure, forming a cylindrical body 1 . One side of the opposite sides of the two halves is hinged by a pivot pin 2, and the other side can be connected by a locking device. The structure of the locking device can be determined according to actual needs, and this embodiment takes three structures as examples. The first type: the locking device is composed of a clamping strip 10, a first clamping tooth 11 and a second clamping tooth 12. The clamping strip 10 is an arc-shaped or curved elongated structure, and one end of the clamping strip 10 is connected to one half body Hinged with each other, a first locking tooth 11 is integrally formed at a position close to the hinge on the clip bar 10, and a second locking tooth 12 that can snap fit wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com