flush toilet

A toilet and flush-down technology, applied in the field of flush-down toilets, can solve problems such as large water consumption, unadjustable water output from the upper flushing outlet pipe, and large toilet volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

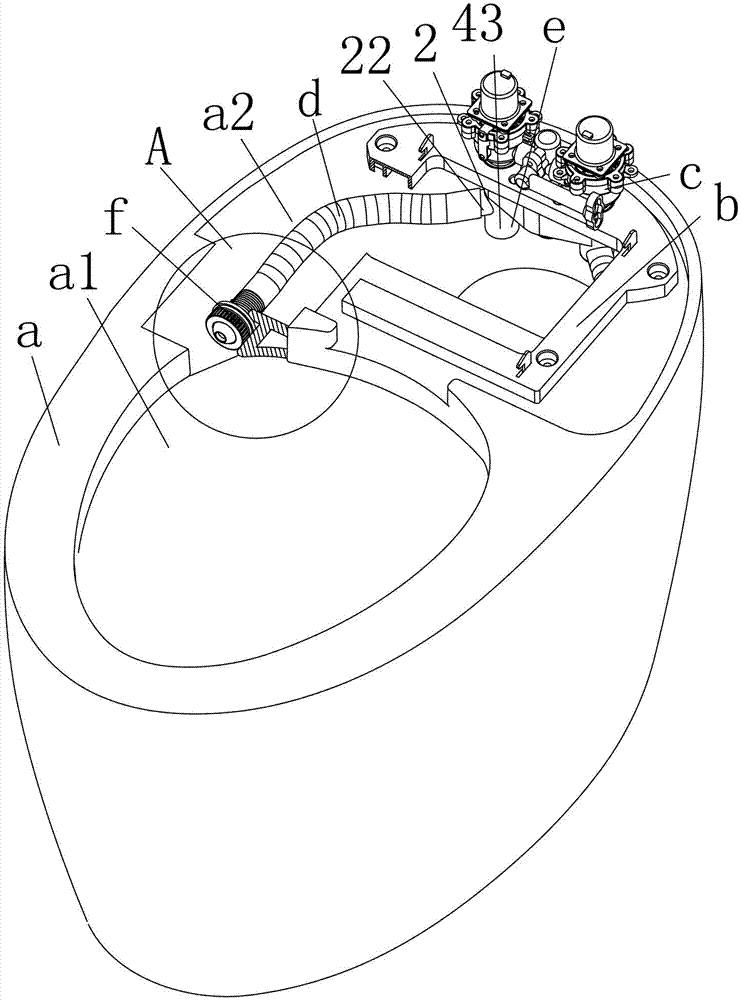

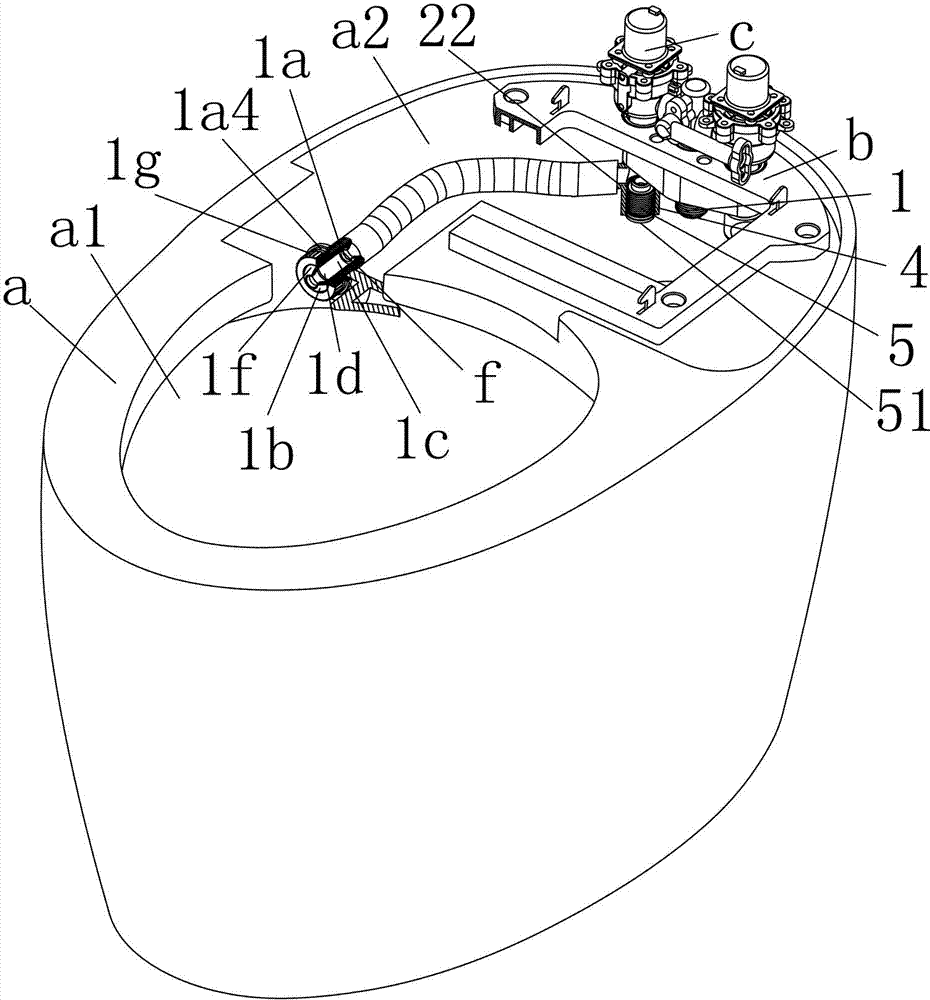

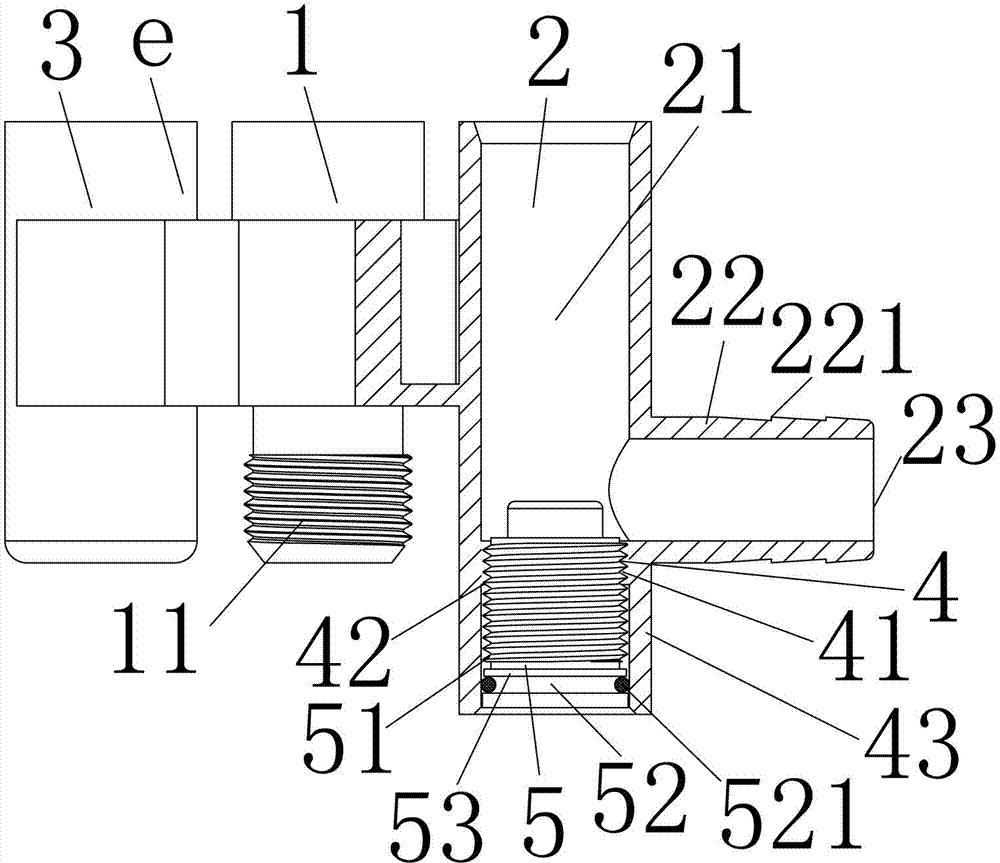

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the embodiment of the flush toilet provided by the present invention includes a body a, a mounting bracket b, a solenoid valve c, a connecting water pipe d, a flushing triple joint e and a flushing spray device f, and the body a includes a pelvic cavity a1 and The component installation part a2, the solenoid valve c is connected to the flushing triplet joint e, the solenoid valve c and the flushing triplet joint e are fixed on the component mounting part a2 through the mounting bracket b, and the flushing triplet joint e includes The water pipe 1, the upper flushing outlet pipe 2 and the lower flushing outlet pipe 3, the water inlet pipe 1 is connected with the upper flushing outlet pipe 2, the water inlet pipe 1 is connected with the lower flushing outlet pipe 3, and the flushing injection device f acts on the pelvic cavity a1, The flushing spray device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com