Driving hammer-type ice-breaking machine

An ice breaker and hammer technology, which can be used in cleaning methods, snow surface cleaning, construction, etc., and can solve the problems of high energy consumption, large space occupation, and low flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

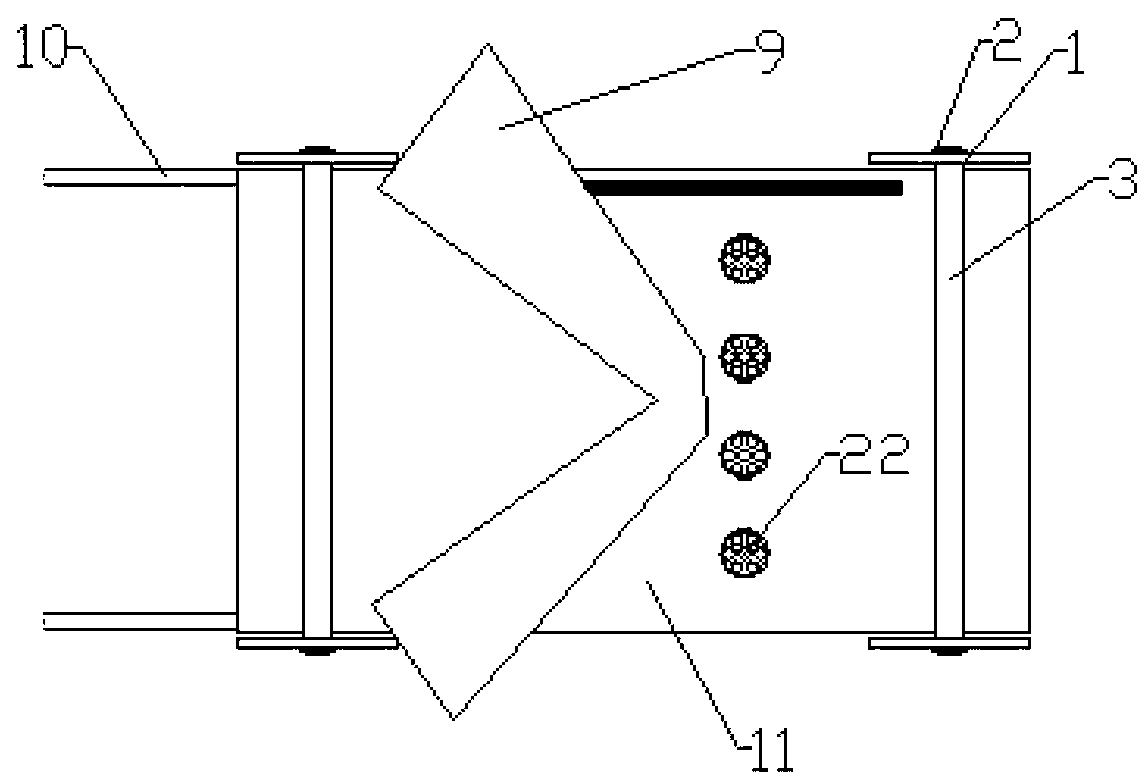

[0026] Such as figure 1 , 2 , 3, 4 shown. The hammer type ice breaker described in the present invention has a specific structure as follows:

[0027] The wheel 1 passes through the wheel axle 3 to form the front wheel and its axle, and the other two wheels pass through the wheel to form the rear wheel and its axle. The axle 3 is fixed on the vehicle frame 11; the crank bracket 15 is fixed on both sides of the vehicle frame 11 The three intermediate crankshaft brackets 19 are respectively equidistantly fixed in the middle of the crankshaft bracket 15, the crankshaft 5 is installed on the crankshaft bracket 15 and the intermediate crankshaft bracket 19, and three intermediate crankshaft bracket fixing plates 19- 1. In order to prevent the crankshaft 5 from jumping during rotation, the four snow hammers 22 are respectively installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com