A kind of preparation method of electroplated diamond grinding wheel for grinding

A technology of electroplating diamond and nickel-plating diamond, applied in electrolytic coatings, electrolytic processes, electrolytic components, etc., can solve the problems of slow sedimentation, formation of metal hard shells, and inability to guarantee quality, achieve good shape retention, and meet high precision , The effect of high-efficiency grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

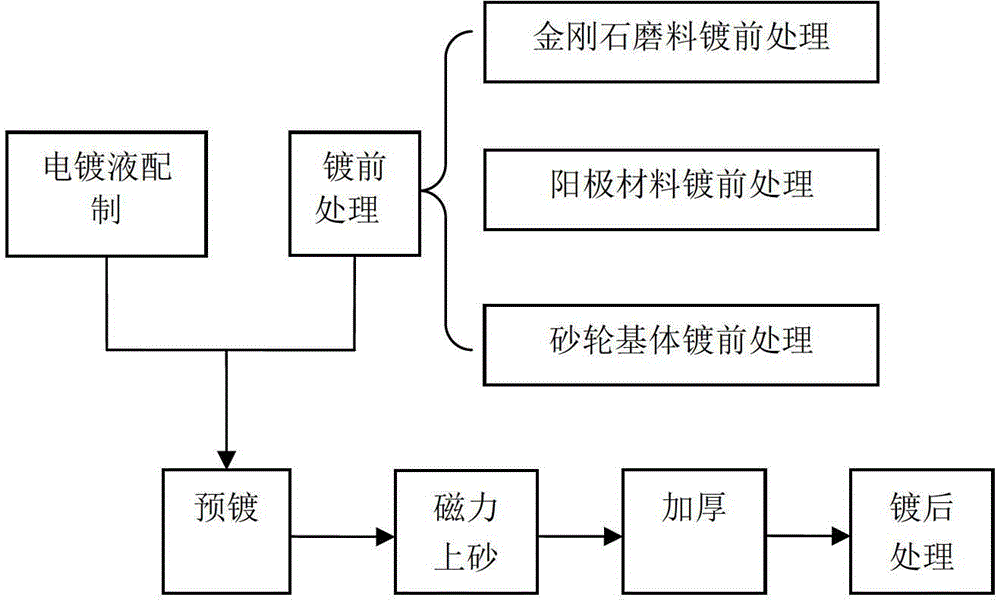

[0038] The preparation method of the electroplated diamond for grinding of the present embodiment, such as figure 1 shown, including the following steps:

[0039] 1) Prepare the electroplating solution, the composition and content of the electroplating solution are shown in Table 1, adjust the pH value of the electroplating solution to 3.8, and control the temperature of the electroplating solution to 50°C;

[0040] 2) Pre-plating treatment: Carry out pre-plating treatment on the diamond abrasive, anode material, and grinding wheel substrate respectively. The diamond abrasive is nickel-plated diamond with a particle size range of 8-12 μm and an average particle size of 10 μm. The mass of nickel in the nickel-plated diamond is The content is 4%; the anode material is metallic nickel; the grinding wheel base is low carbon steel.

[0041] Diamond abrasive pre-plating treatment: put nickel-plated diamond into 5% H 2 SO 4 Etched in the solution for 20s, then took it out and was...

Embodiment 2

[0049] The preparation method of the electroplated diamond for grinding of the present embodiment, such as figure 1 shown, including the following steps:

[0050] 1) Prepare the electroplating solution, the composition and content of the electroplating solution are shown in Table 1, adjust the pH value of the electroplating solution to 4.0, and control the temperature of the electroplating solution to 60°C;

[0051] 2) Pre-plating treatment: Carry out pre-plating treatment on diamond abrasives, anode materials, and grinding wheel substrates respectively. The diamond abrasives are nickel-plated diamonds with a particle size range of 5-10 μm and an average particle size of 8 μm. The mass of nickel in nickel-plated diamonds is The content is 3%; the anode material is metal nickel; the grinding wheel base is low carbon alloy steel.

[0052] Diamond abrasive pre-plating treatment: put nickel-plated diamond into 4% H 2 SO 4 Etch in the solution for 20s, then take it out and wash...

Embodiment 3

[0060] The preparation method of the electroplated diamond for grinding of the present embodiment, such as figure 1 shown, including the following steps:

[0061] 1) Prepare the electroplating solution, the composition and content of the electroplating solution are shown in Table 1, adjust the pH value of the electroplating solution to 4.2, and control the temperature of the electroplating solution to 55°C;

[0062] 2) Pre-plating treatment: Carry out pre-plating treatment on diamond abrasives, anode materials, and grinding wheel substrates respectively. The diamond abrasives are nickel-plated diamonds with a particle size range of 10-20 μm and an average particle size of 15 μm. The mass of nickel in nickel-plated diamonds is The content is 5%; the anode material is metallic nickel; the grinding wheel base is No. 40 steel.

[0063] Diamond abrasive pre-plating treatment: put nickel-plated diamond into 6% H 2 SO 4 Etched in the solution for 20s, then took it out and washed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com