Improved method for producing pigment carbon black

A pigment carbon black, carbon black technology, applied in the direction of fibrous fillers, can solve the problems of unreachable, high dispersibility, etc., and achieve the effects of short oxidation time, high dispersibility, and high volatile content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

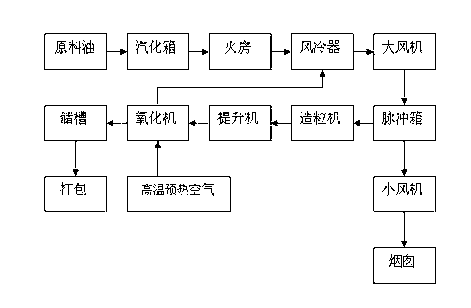

Method used

Image

Examples

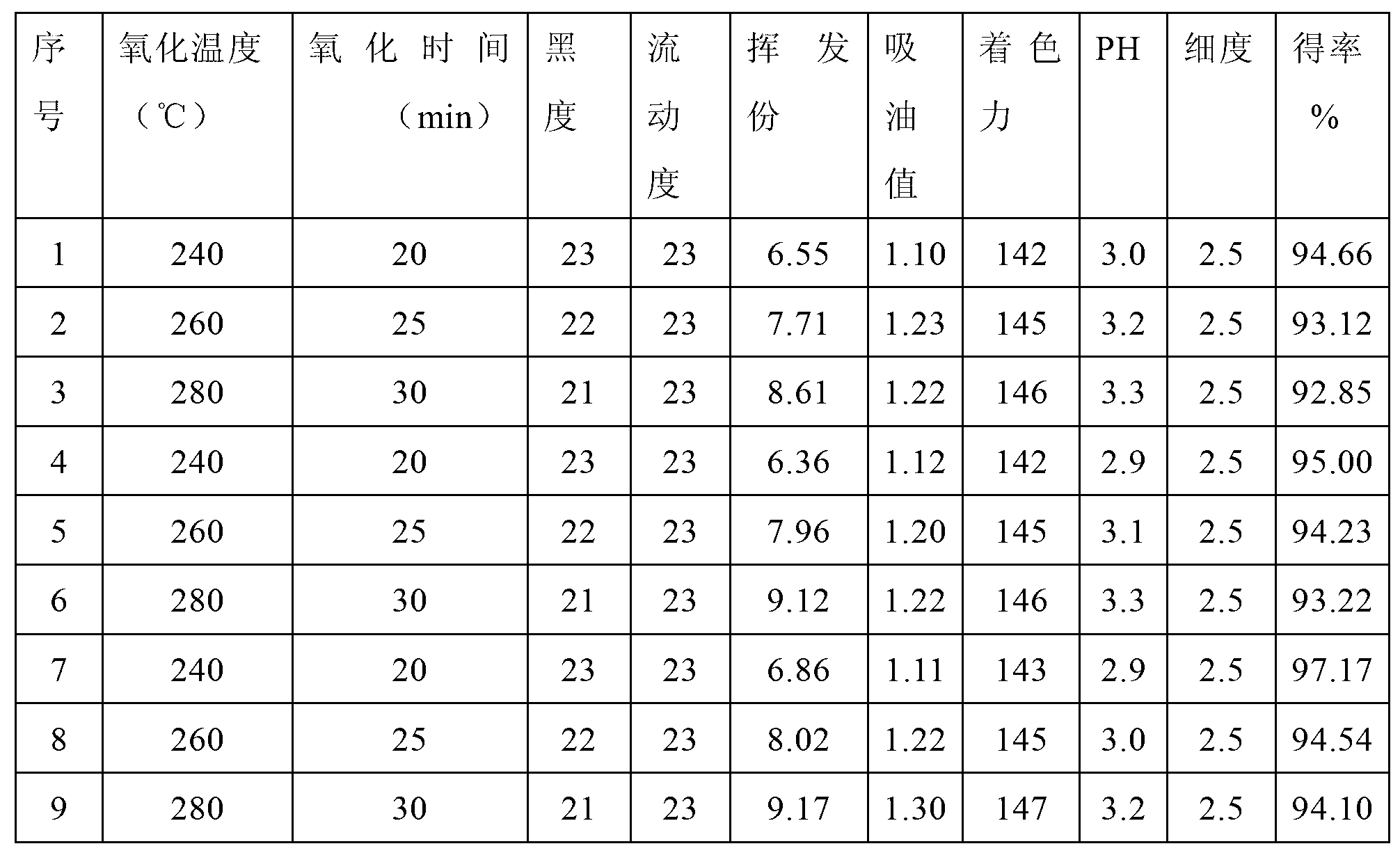

Embodiment 1

[0025] Embodiment 1: carbon black base sample is 100kg, and oxidation time is 20min, and hot air flow rate is 200m 3 / h, the constant temperature of the oxidation machine is controlled at 240°C.

Embodiment 2

[0026] Embodiment 2: carbon black base sample is 100kg, and oxidation time is 25min, and hot air flow rate is 250m 3 / h, the constant temperature of the oxidation machine is controlled at 260°C.

Embodiment 3

[0027] Embodiment 3: the carbon black base sample is 100kg, the oxidation time is 30min, and the hot air flow is 300m 3 / h, the constant temperature of the oxidation machine is controlled at 280°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com