Method for preparing nickel oxide electrochromic film by hydrothermal method

An electrochromic and nickel oxide technology, which is applied in the direction of nickel oxide/nickel hydroxide, etc., can solve the problems of difficulty in preparing a large-area uniform NiO film, difficulty in meeting practical application requirements, and weak adhesion between the film and the substrate. Excellent cycle stability, beneficial to electron conduction, and the effect of improving electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

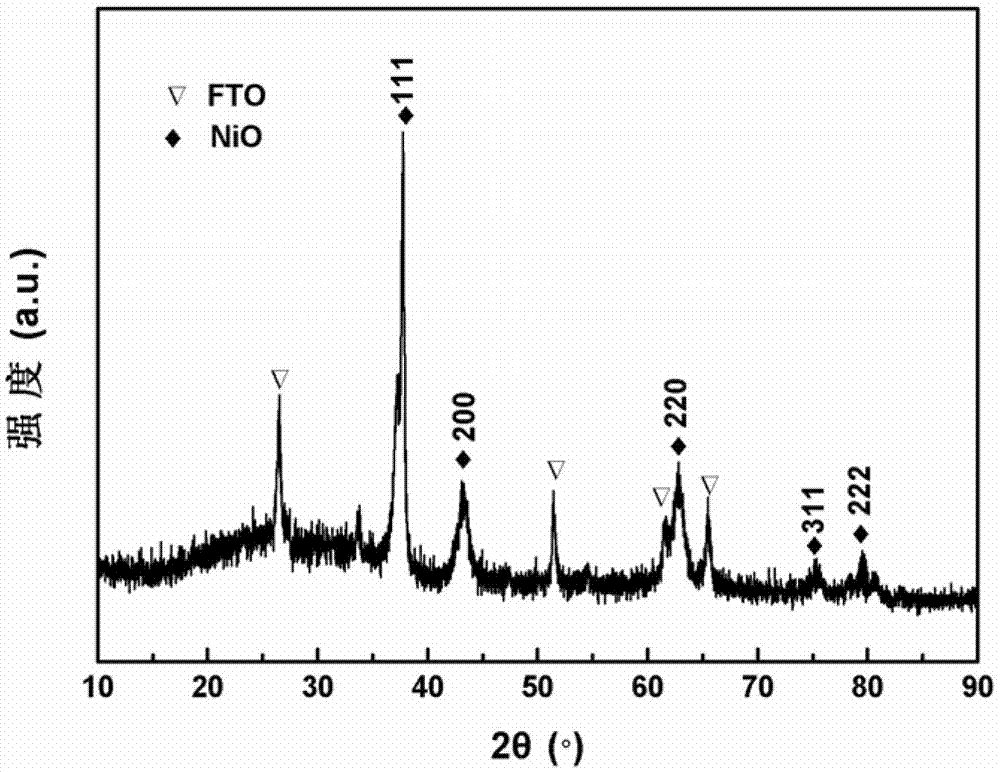

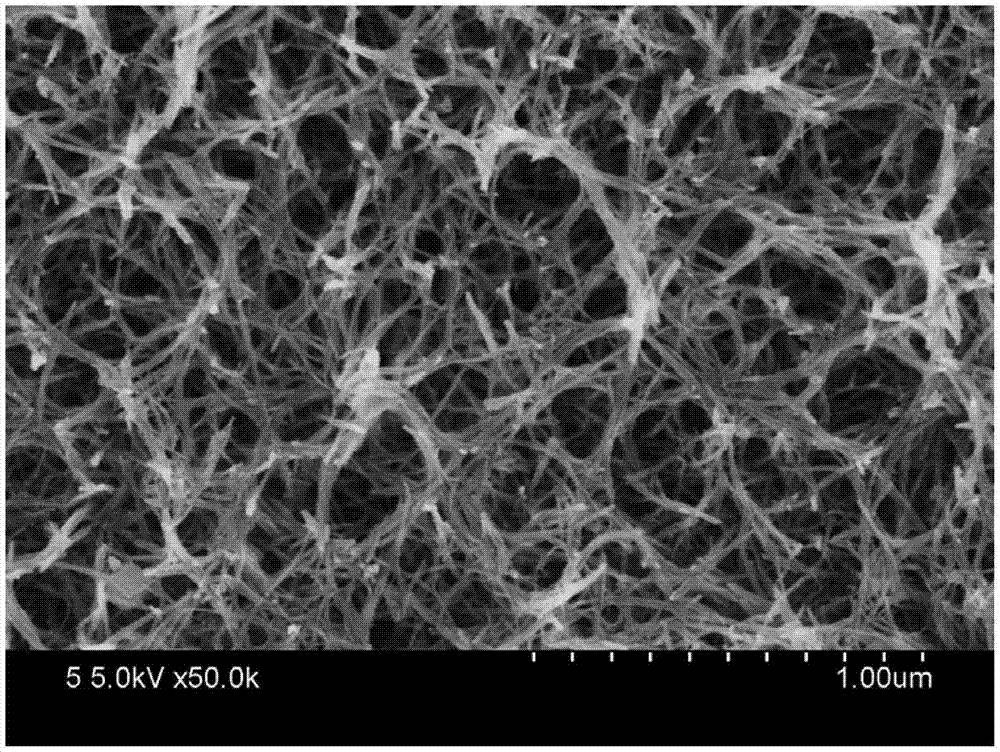

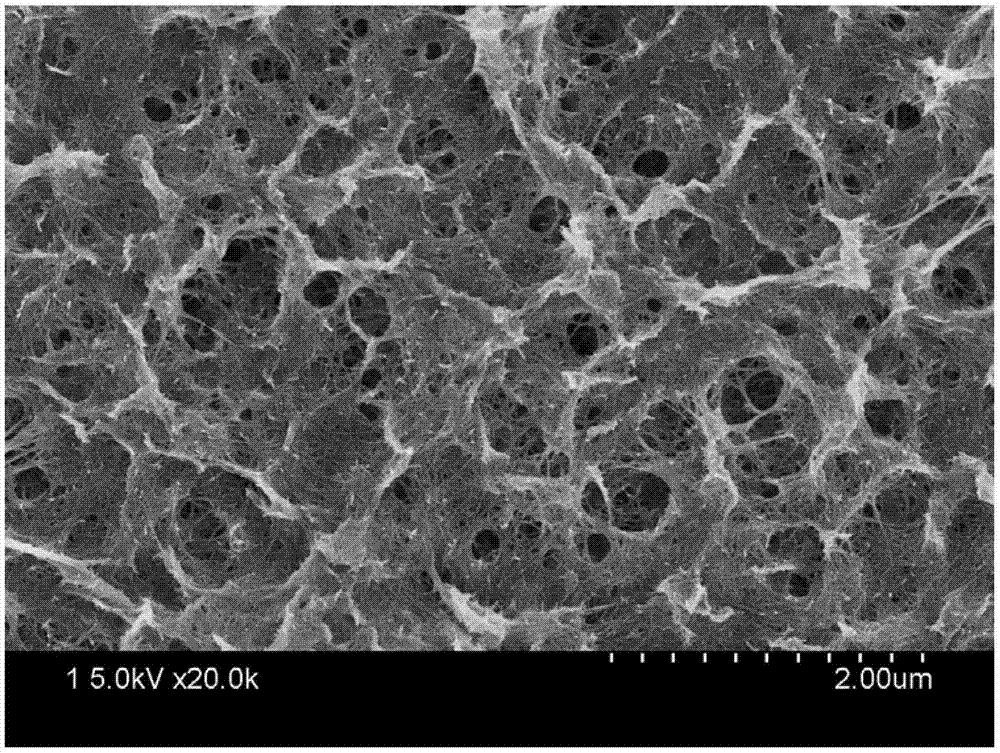

[0031] The FTO conductive glass was sequentially immersed in deionized water, acetone and ethanol, respectively, ultrasonically washed and dried for later use. Weigh 0.45g of nickel acetate tetrahydrate and dissolve it in a mixed solution of 6mL of ethanol and 3mL of n-butanol. After the nickel acetate tetrahydrate is completely dissolved, add 0.12mL of concentrated ammonia water dropwise to obtain a transparent sol; then spin-coat the transparent sol on an ultrasonically cleaned The FTO conductive glass surface was vacuum-dried at 40° C. for 12 hours to obtain a nickel hydroxide seed layer. Prepare a reaction solution containing 0.6g of nickel acetate tetrahydrate, 0.6g of urea, and 56mL of water, then intrude the above-obtained FTO conductive glass with a seed layer into a hydrothermal kettle containing the reaction solution, and keep it warm at 180°C for 6 hours , and finally cooled naturally to room temperature, took out the FTO conductive glass, washed with water and etha...

Embodiment 2

[0034] The FTO conductive glass was sequentially immersed in deionized water, acetone and ethanol, respectively, ultrasonically washed and dried for later use. Weigh 0.9g of nickel acetate tetrahydrate and dissolve it in a mixed solution of 7.5mL of ethanol and 2.5mL of n-butanol. After nickel acetate tetrahydrate is completely dissolved, add 0.24mL of concentrated ammonia water dropwise to obtain a transparent sol; then spin coat the transparent sol on an ultrasonic The cleaned FTO conductive glass surface was vacuum-dried at 60° C. for 6 hours to obtain a nickel hydroxide seed layer. Prepare a reaction solution containing 0.6g of nickel acetate tetrahydrate, 0.3g of urea, and 56mL of water, then intrude the above-obtained FTO conductive glass with a seed layer into a hydrothermal kettle containing the reaction solution, and keep it warm at 160°C for 12 hours , and finally cooled naturally to room temperature, took out the FTO conductive glass, washed with water and ethanol i...

Embodiment 3

[0037] The FTO conductive glass was sequentially immersed in deionized water, acetone and ethanol, respectively, ultrasonically washed and dried for later use. Weigh 0.6g of nickel acetate tetrahydrate and dissolve it in a mixed solution of 7mL of ethanol and 2mL of n-butanol. After the nickel acetate tetrahydrate is completely dissolved, add 0.16mL of concentrated ammonia water dropwise to obtain a transparent sol; then spin-coat the transparent sol on an ultrasonically cleaned The FTO conductive glass surface was vacuum-dried at 50° C. for 8 hours to obtain a nickel hydroxide seed layer. Prepare a reaction solution containing 0.3g of nickel acetate tetrahydrate, 0.3g of urea, and 56mL of ethanol, then intrude the above-obtained FTO conductive glass with a seed layer into a hydrothermal kettle containing the reaction solution, and keep it warm at 170°C for 8 hours , and finally cooled naturally to room temperature, took out the FTO conductive glass, washed with water and etha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com