Mining oxygen candle protection and purification system

A purification system, oxygen candle technology, applied in heat exchange and protection devices, mine oxygen candle protection and purification system, oxygen candle gas purification field, can solve the lack of experience and standards, the difficulty of survival guarantee, the delay of mine rescue cabin To avoid scald injury, eliminate odor and dust pollution, and ensure oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

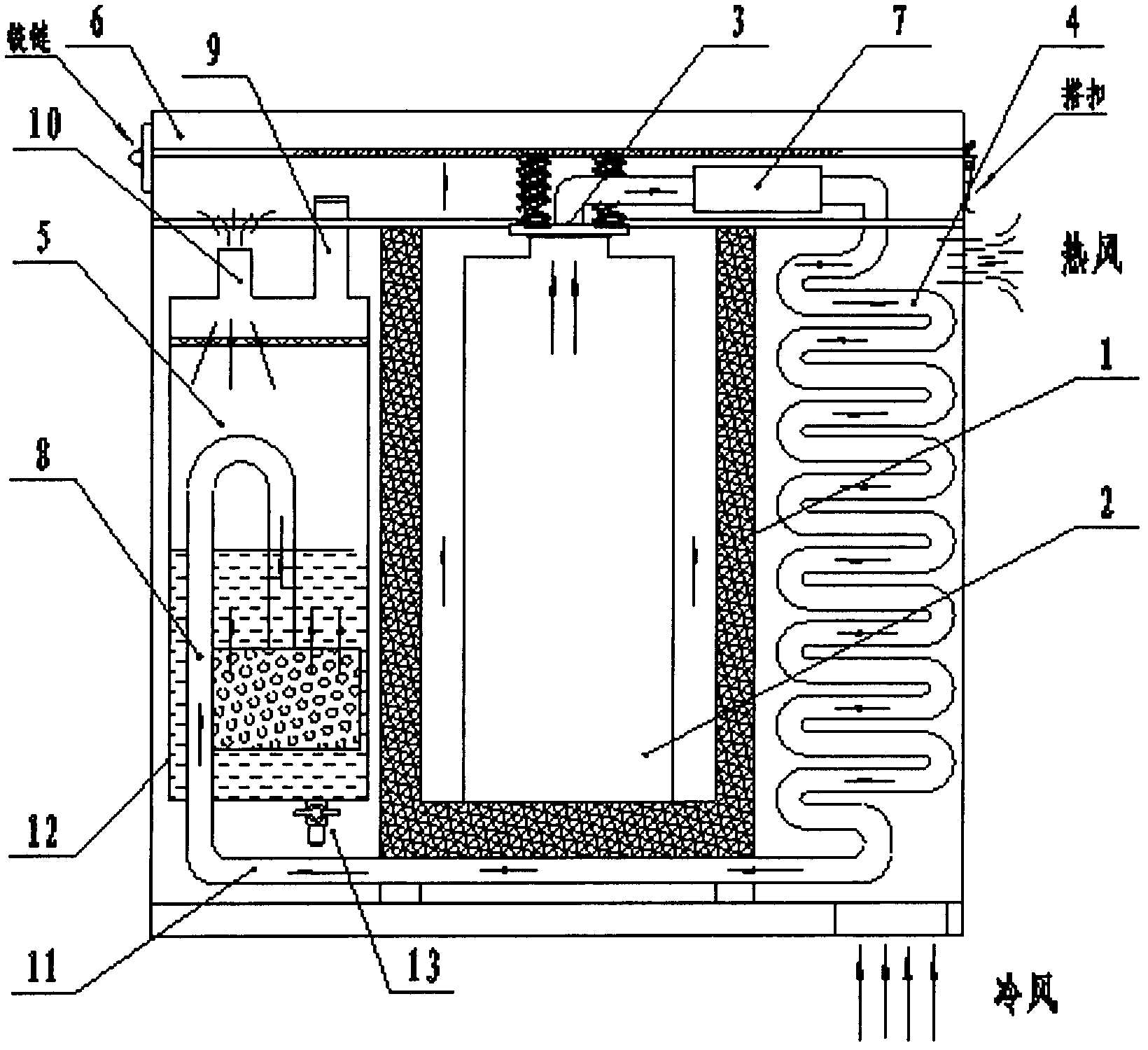

[0013] like figure 1 As shown, the mine oxygen candle protection and purification device includes a cylinder body 1, a gas collection transfer mechanism 3, a heat exchanger 4, a filter 5, a top cover 6, an oxygen candle generator 2 and a shell protection component. Cylinder 1 is an inner and outer double-layer body, and the middle of the inner and outer bodies is filled with heat-insulating and sound-insulating materials. The cylinder 1 is a square structure, and the inner cavity is placed with the oxygen candle generator 2, and the oxygen candle gas outlet of the oxygen candle generator 2. There is a gas-collecting transfer mechanism 3; there are heat exchangers 4 and filters 5 on the left and right sides of the oxygen candle generator 2 in the cylinder 1, and the bottom is connected through the connecting pipe 11, and the gas-collecting transfer mechanism 3 is connected to the The heat exchanger 4 is connected; the filter 5 includes a body 12, a separator 10, a sound-absorbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com