Large roll of net roll for paper forming net inspection and its wrapping method

A paper-making forming wire and wire rolling machine technology, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc. Better effect, less damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Press one end of the smooth special flat belt figure 1 The dotted line shown cut off a corner whose length is equal to the circumference of the big roller 1284.26mm, and the width is equal to the width of the special flat belt 70mm; the special flat belt is a flat rubber Bobotex imported from Germany.

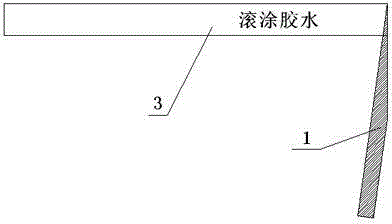

[0018] (2) Roll glue on the adhesive surface of the large roller and the special flat belt; choose Terokaltransparent or Loctite 2444 for the glue.

[0019] (3) if figure 2 As shown, starting from one side of the big roller, use a corner of the smooth special flat tape to start pasting, and at the same time, the big roller rolls the glue until the whole roll of special flat tape is pasted on the big roller.

[0020] (4) Take another roll of special flat belt and repeat steps (1), (2) and (3) until the surface of the large roll is completely covered with special flat belt.

[0021] The large roll after wrapping the flat belt such as image 3 As shown, its surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com