A device for improving the surface smoothness of the intake and exhaust ducts of the cylinder head of an internal combustion engine

A surface smoothness, internal combustion engine cylinder technology, applied in the direction of abrasive feeding device, used abrasive processing device, abrasive jet machine tool, etc., can solve the problems affecting the performance of the engine, the surface of the intake and exhaust passages is not smooth enough, etc., to achieve improvement Surface finish, improved consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

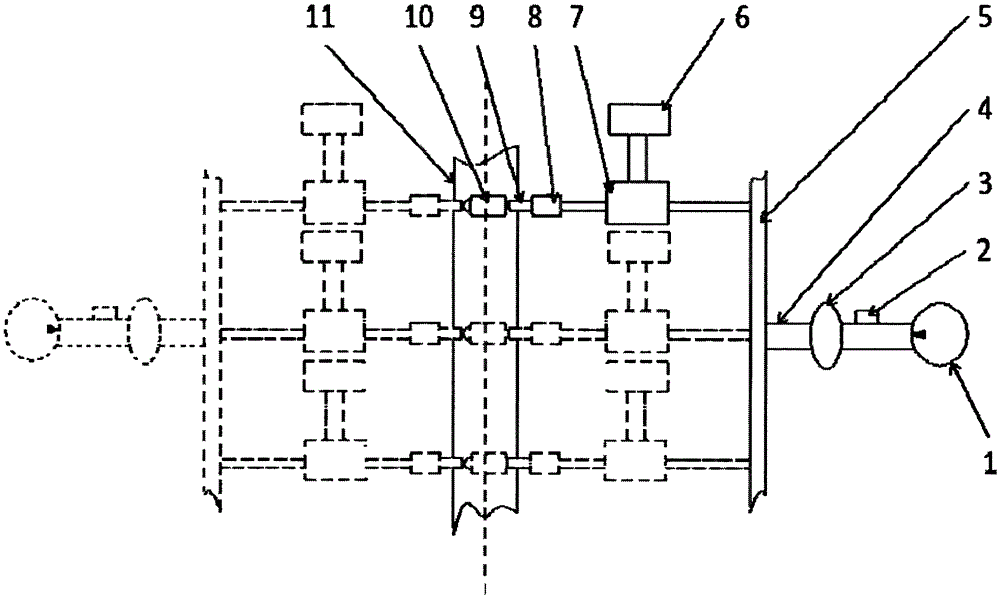

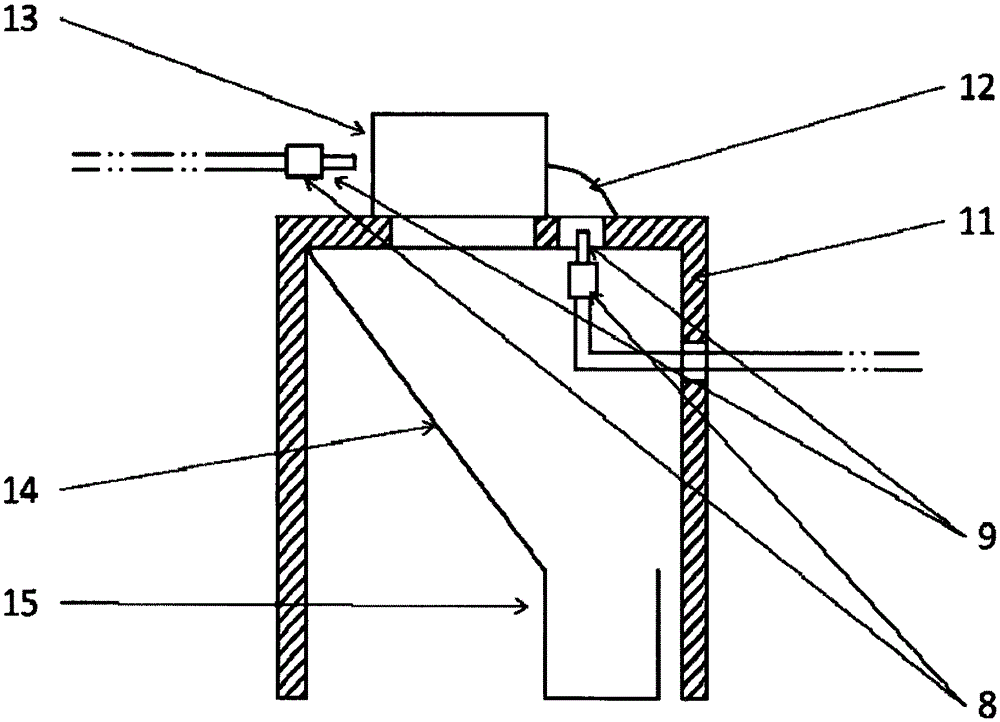

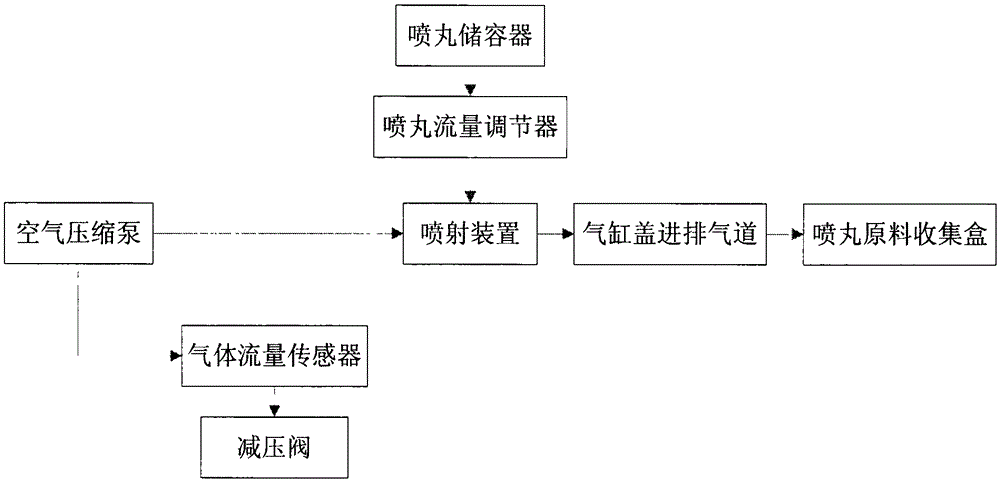

[0024] combine figure 1 and figure 2 The structure of the device table for improving the surface smoothness of the cylinder head intake and exhaust passages is described in detail: figure 1 Only the middle part of the device table is drawn in the figure, and the rest are exactly the same as the middle part. figure 2 It is a side view of the device table. The device table includes an air compression pump 1, a gas flow sensor 2, a pressure reducing valve 3, a gas supply pipeline 4, a high-pressure air common rail 5, a shot blast storage container 6, a shot blast flow regulator 7, a spray gun 8, a nozzle 9, Cylinder head 10 (comprising cylinder head intake duct 12 and cylinder head exhaust duct 13), cylinder head placement table 11, inclined plane 14 and shot blasting raw material collection box 15. The function of the air compression pump 1 is to provide high-pressure air flow for the system; the pressure reducing valve 3 is selectively opened and closed according to the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com