Flat round-corner-shaped bead welding rod having coatings with different thicknesses

A technology of surfacing electrodes and rounded corners, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the effect of surfacing electrode surfacing efficiency on surfacing wear resistance, and cannot manufacture large-sized thick coatings The thickness of the coating of the surfacing electrode and the flat electrode should not be too thick, so as to achieve the effect of no arcing phenomenon, solving the problem of surfacing efficiency and stable surfacing operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: The flat fillet-shaped surfacing electrode with different thickness coatings used, the thickness H of the welding core 1 is 1.6mm, the radius R of the fillet 4 is 0.8mm, and the cross-sectional area of the welding core is the same as that of a Φ3.2mm round rod-shaped welding rod. The cores are the same (the diameter of the welding core is Φ3.2mm, and the thickness of the coating is 1.4mm.), the thickness of the coating 2 outside the two flat surfaces 3 is 1.6mm, and the thickness of the coating 2 outside the two rounded corners 4 is 1.2mm. The round rod-shaped surfacing electrode can perform normal surfacing welding when the welding current is 130-150A, and the flat round-shaped surfacing electrode with different thickness coatings can produce beautiful welds under the condition of 80A welding current. When it is increased to 170A, a flat and smooth weld can also be surfacing, and the surfacing speed is 0.5 times that of the normal surfacing speed of the ...

Embodiment 2

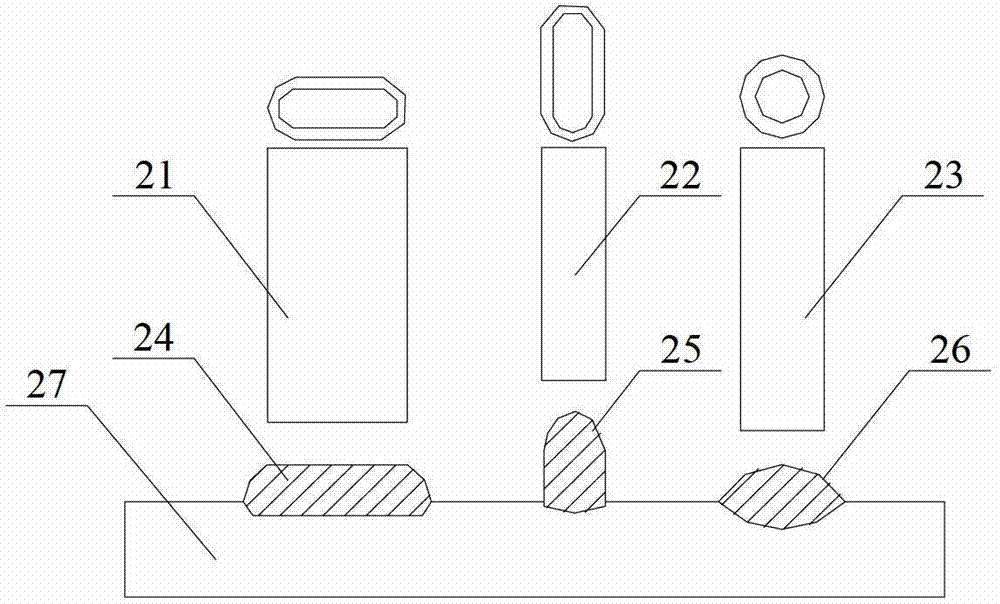

[0030] Embodiment 2: as figure 2As shown, the round bar-shaped surfacing electrode used, the diameter of the welding core is Φ4.0mm, and the thickness of the coating is 1.8mm, which is a thick-coating surfacing electrode. Among them, the flat fillet-shaped surfacing electrode with different thickness coatings is used. The thickness H of the welding core 1 is 2mm, the radius R of the fillet 4 is 1mm, and the cross-sectional area of the welding core is the same as that of the Φ4.0mm round rod-shaped welding core. The thickness of the coating 2 outside the surface 3 is 2.5mm, and the thickness of the coating 2 outside the two rounded corners 4 is 1.6mm. Since the flat shape has a larger surface area than the round rod shape, and the thickness of the coating on the two flat surfaces is large, Therefore, the total amount of coating applied by flat and rounded surfacing electrodes with different thicknesses is more. These two kinds of surfacing welding electrodes are manufacture...

Embodiment 3

[0035] Embodiment 3: as image 3 As shown, the diameter of the welding core of the round rod-shaped surfacing electrode used is Φ5.0mm, and the thickness of the coating is 2.0mm. The thickness H of welding core 1 is 3.0mm, the radius R of fillet 4 is 1.5mm, and the cross-sectional area of welding core is calculated as the welding rod of Φ8.0mm specification. The thickness of the coating 2 outside the surface 3 is 3.0 mm, and the thickness of the coating 2 outside the two rounded corners 4 is 2.0 mm. These two kinds of surfacing electrodes are manufactured with the same formula, but the specifications of the welding core and the proportion of the coating are different. The two kinds of electrodes are used for comparison in the way of multi-pass continuous surfacing welding on the same base metal 27 .

[0036] With a round bar-shaped surfacing electrode, the welding current is 190A, and the surface of the round bar-shaped electrode surfacing welding seam 32 on the base metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com