Foam breaker

A defoamer and cylinder technology, applied in chemical instruments and methods, separation methods, use of liquid separation agents, etc., can solve the problems of flue gas containing moisture or high foam, tailing, white smoke, etc., to eliminate Fog, reduce white smoke from chimneys, eliminate air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following specific descriptions of the present invention are given by the examples, which are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention.

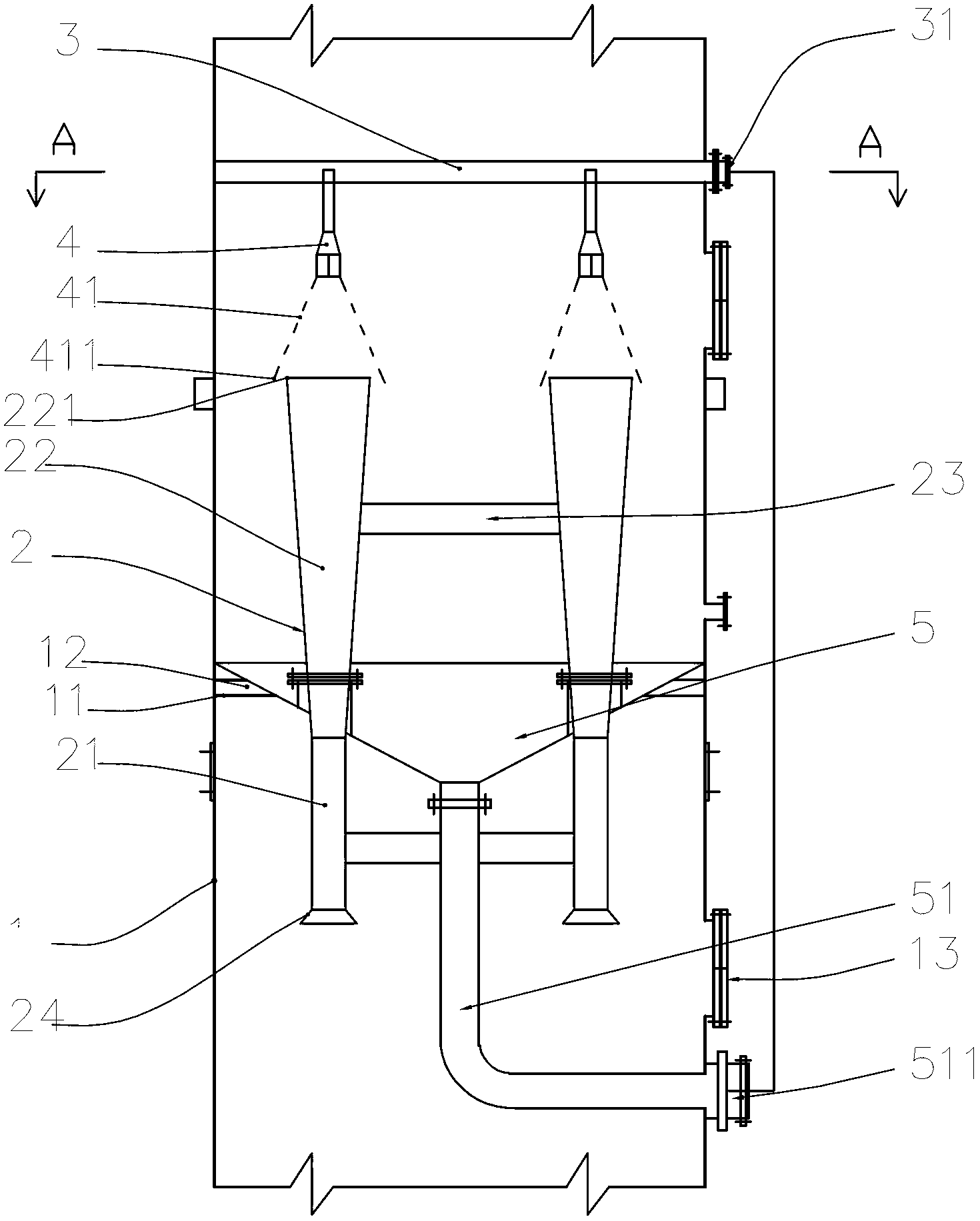

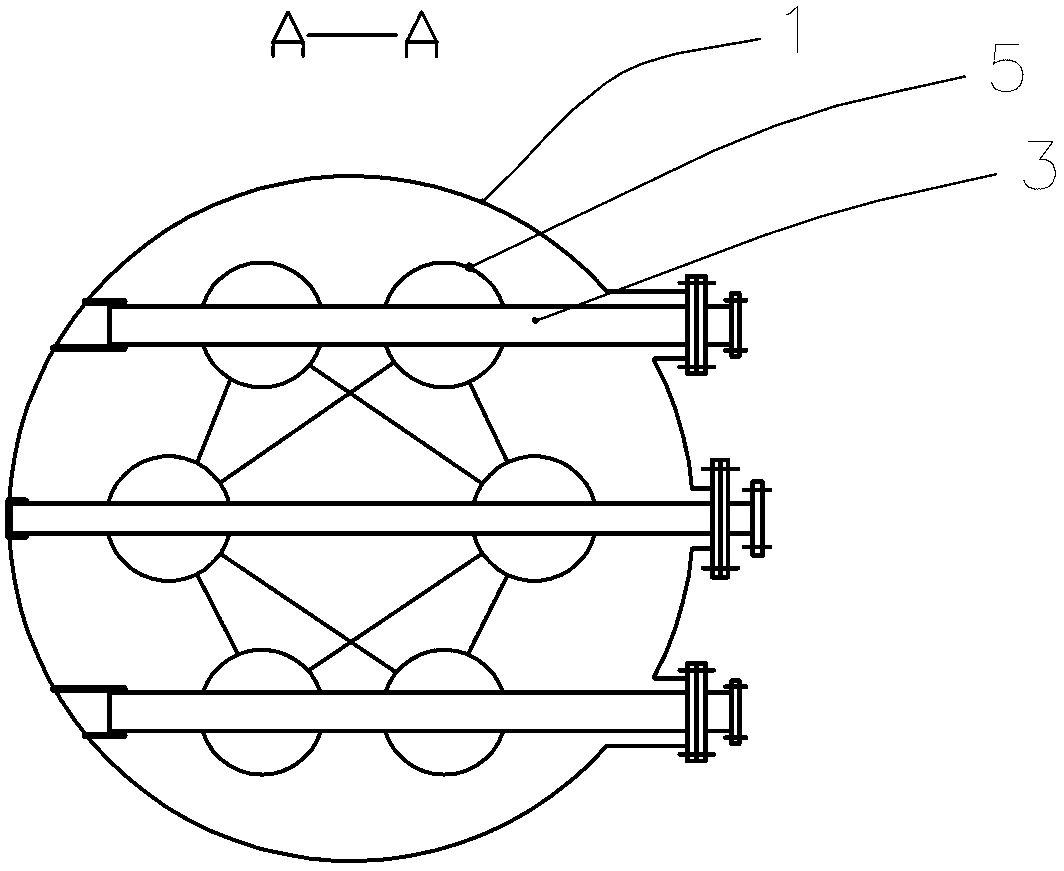

[0025] Such as Figure 1-2 The specific embodiment of the present invention shown includes a defoamer cylinder body 1, and a Venturi tube bundle composed of a plurality of Venturi tubes 2 arranged side by side is fixedly arranged in the defoamer cylinder body 1, each The Venturi tube 2 includes a constriction section 24 that gradually decreases in the inner diameter, a throat pipe 21, and a diffuser section 22 that is connected to the upper end of the throat pipe 21 and gradually expands in the inner diameter direction. The inner wall of the defoamer cylinder 1 is opposite to the diffuser section The upper end of the spray pipe 3 is fixedly provided with a spray pipe 3, and the number and position of the spray pipe 3 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com