Sintered metal fiber filtering material and preparation method thereof

A sintered metal and fiber filtration technology, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of small pollution holding capacity, high cost, shortened service life of the filter element, etc., and achieve high filtration accuracy and flux. The effect of large and strong dirt holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

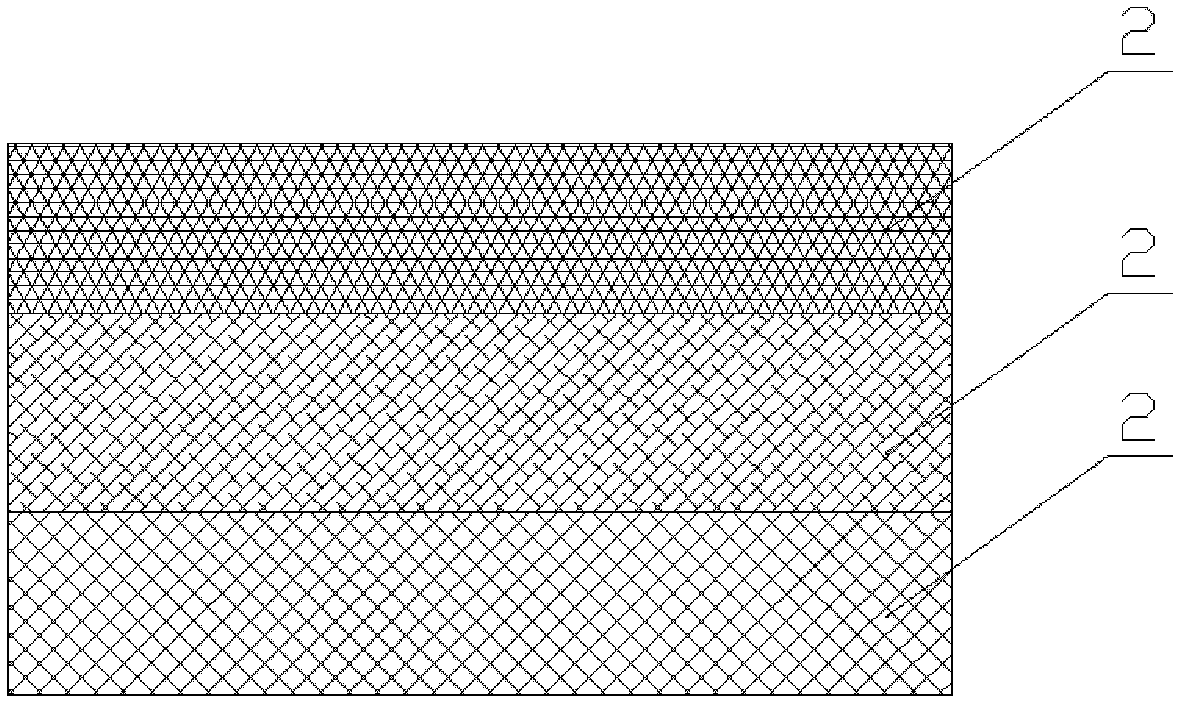

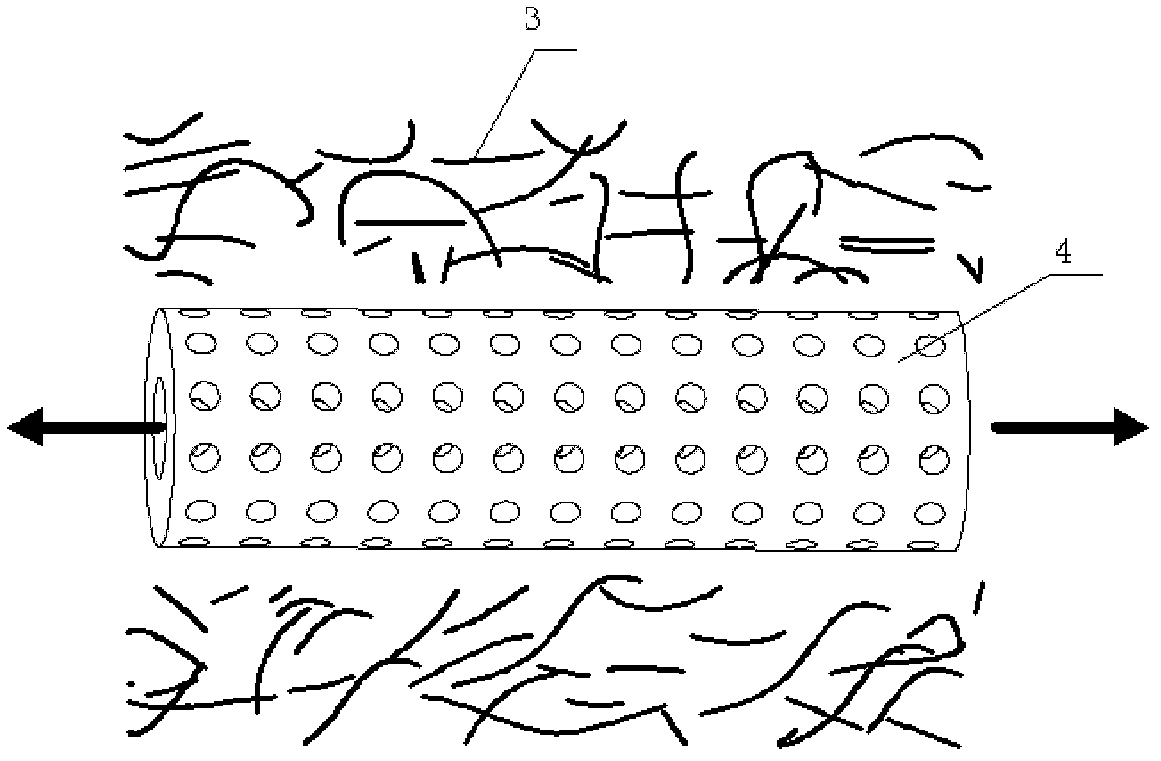

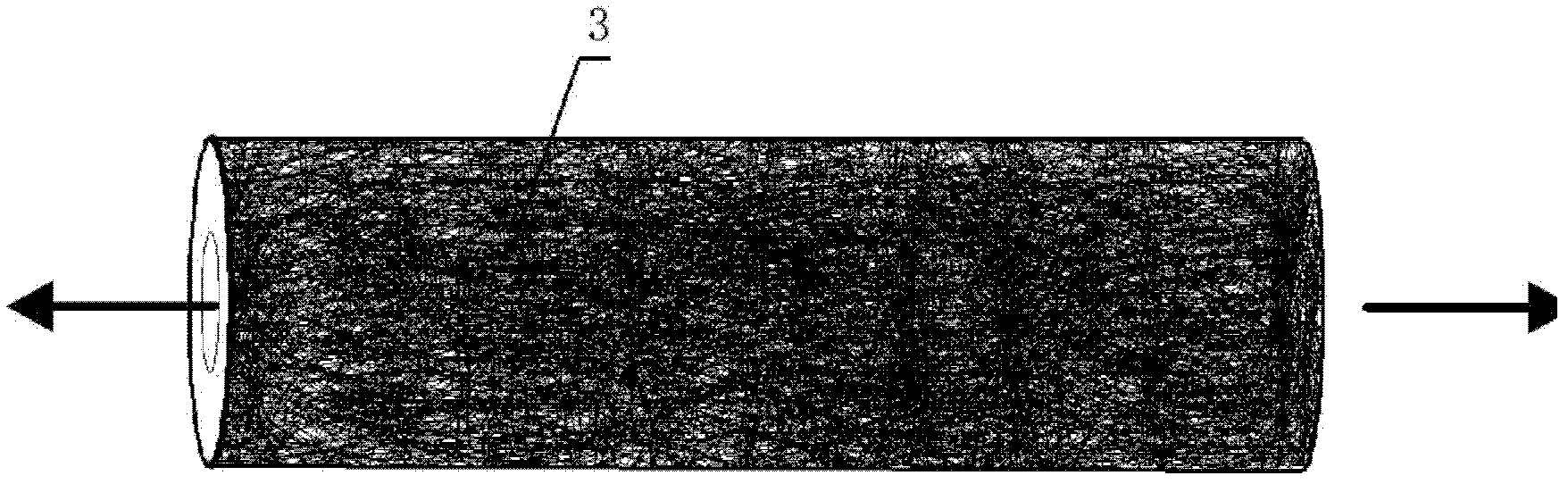

[0025] Embodiment 1: A sintered metal fiber filter material, which is composed of three layers of sintered metal fiber mats. The sintered metal fiber felts of each layer decrease in pore size from large to small along the direction of fluid inflow, and finally form a thickness of 0.8mm. The porosity 82%, the filter precision is 20μm composite filter material layer.

[0026] The preparation method of the above-mentioned sintered metal fiber filter material is as follows: the grades of 316L stainless steel fibers with diameters of 8 μm, 12 μm and 20 μm are cut into short fibers with a length of 3.5 cm by an automatic fiber cutter; Fibers with a diameter of 8 μm were prepared by Lando air-flow deposition method with a unit weight of 300 g / m 2 The soft metal fiber felt is then properly compacted with a two-roller press; then the fibers with a diameter of 12 μm and 20 μm are prepared by the Lando airflow deposition method into a unit weight of 300 g / m 2 The soft and soft metal fib...

Embodiment 2

[0027] Embodiment 2: A sintered metal fiber filter material, which is composed of three layers of sintered metal fiber mats. The sintered metal fiber mats of each layer decrease in pore size from large to small along the direction of fluid inflow, and finally form a thickness of 0.8mm. The porosity 84%, the filter accuracy is 40μm composite filter material layer.

[0028] The preparation method of the above-mentioned sintered metal fiber filter material is as follows: first cut the 316L stainless steel fibers with a diameter of 20 μm, 30 μm and 40 μm into short fibers with a length of 4.0 cm with an automatic fiber cutter; Fibers with a cm diameter of 20 μm and a unit weight of 300 g / m were prepared by Lando air-flow deposition 2 The soft metal fiber felt is then properly compacted by a two-roller press; and then the fibers with a diameter of 30 μm and 40 μm are prepared by the Lando airflow deposition method into a unit weight of 300 g / m 2 The soft metal fiber mats are compa...

Embodiment 3

[0029]Embodiment 3: A sintered metal fiber filter material, which is composed of three layers of sintered metal fiber mats. The sintered metal fiber mats of each layer decrease in pore size from large to small along the direction of fluid inflow, and finally form a thickness of 0.78mm. The porosity 80%, the filter precision is 10μm composite filter material layer.

[0030] The preparation method of the above-mentioned sintered metal fiber filter material is as follows: the 316L stainless steel fiber with a diameter of 4 μm, 8 μm and 12 μm is cut into short fibers with a length of 3.0 cm by an automatic fiber cutter, and then the fiber with a length of 3.0 cm Fibers with a cm diameter of 4 μm and a unit weight of 200 g / m were prepared by Lando air-flow deposition 2 The soft metal fiber mat is then properly compacted with a two-roller press, and then the fibers with a diameter of 8 μm and 12 μm are prepared by the Lando air-flow deposition method into a unit weight of 350 g / m 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com