Filter material for coal-fired boilers and preparation method thereof

A technology for coal-fired boilers and filter materials, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of not enough to affect the service life of PPS filter materials, non-compliance, low longitudinal and transverse fracture strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

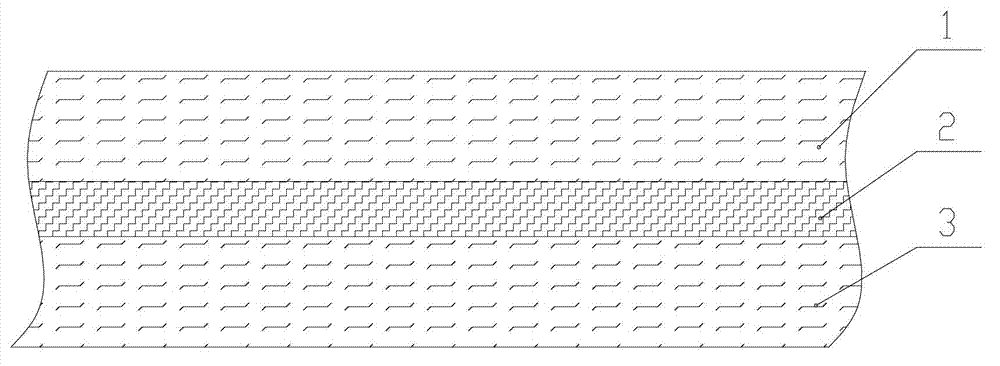

[0019] like figure 1 As shown, the coal-fired boiler filter material is provided with a base cloth layer 2, and on both sides of the base cloth layer 2, a fiber filter layer 1 on the dust-facing surface and a fiber filter layer 3 on the air-cleaning surface are respectively provided.

[0020] The base cloth layer 2 adopts 100% PTFE material layer, the thickness of the base cloth layer is 0.3mm, and the grammage is 110~140g / m 2 .

[0021] The fiber filter layer 1 on the dust-facing surface adopts a blended layer of PPS fiber and PTFE fiber, or a blended layer of PI fiber and PTFE fiber, and the fiber filter layer 3 on the clean air side adopts a blended layer of PPS fiber and PTFE fiber, or a blended layer of PI fiber and PTFE fiber. Fiber blend layer.

[0022] The PTFE fiber in the PPS fiber and PTFE fiber blended layer accounts for 10%-85% by mass percentage.

[0023] The PTFE fibers in the blended layer of PI fibers and PTFE fibers account for 75% to 85% by mass.

[0024...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com