Fruit ice cream machine

An ice cream machine and fruit technology, which is applied in the fields of frozen desserts, food science, and application, can solve problems such as retention and waste, and achieve the effect of improving the effect, speeding up the discharge speed, and speeding up the discharge speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

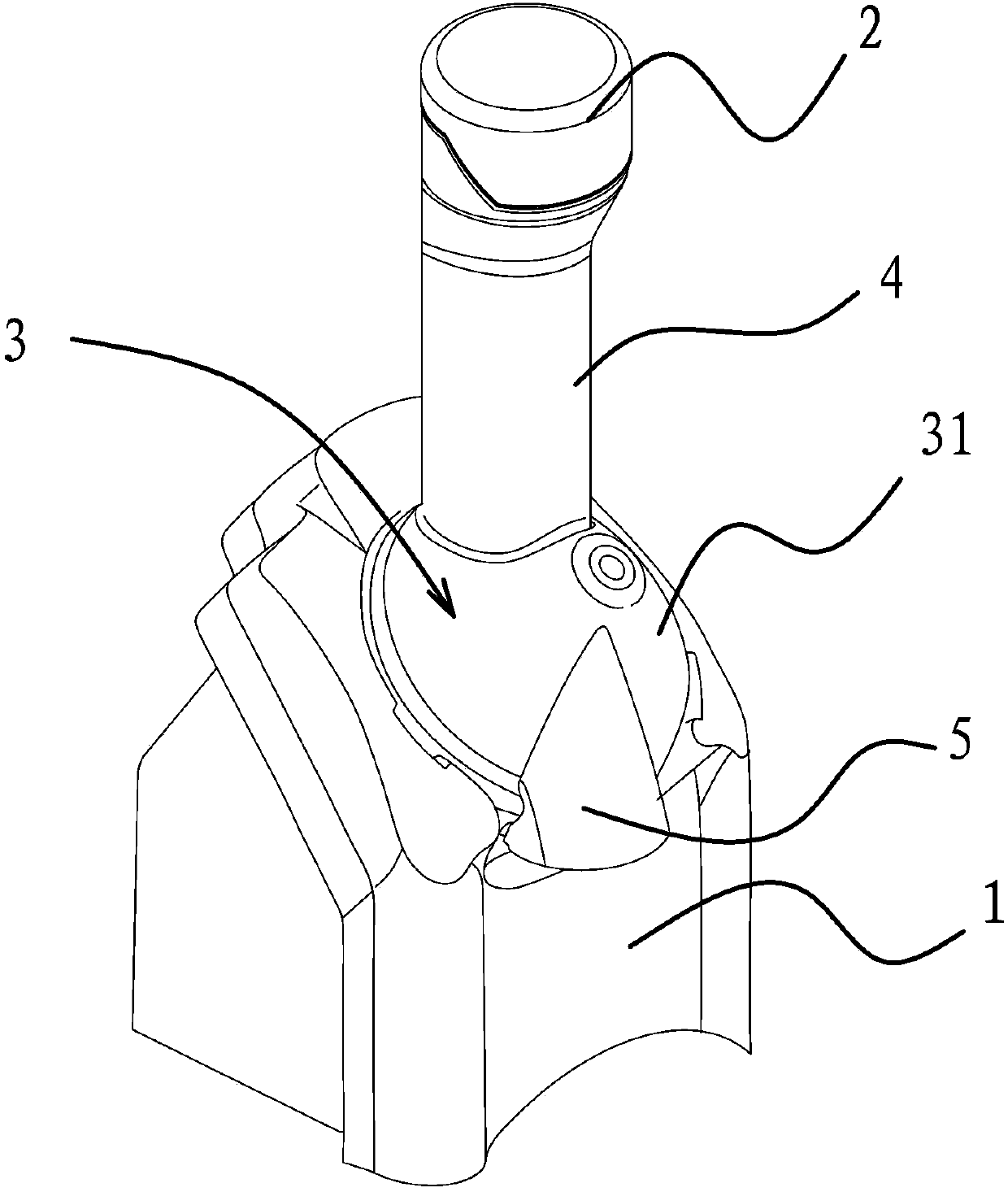

[0041] Such as figure 1 This fruit ice cream machine is a household food equipment that chops and stirs frozen fruits to make ice cream-like cold products, such as figure 1 As shown, a storage bin 3 is established above the base 1 and the base 1, and the storage bin is composed of a cylindrical feed tube 4 and a conical gland 31, and the gland has a Outlet 5. The gland 31 and the container cover 6 form a closed mixing chamber 7 , and both the feeding cylinder 4 and the discharge port 5 communicate with the mixing chamber 7 . Push rod 2 is also provided in feeding cylinder 4 .

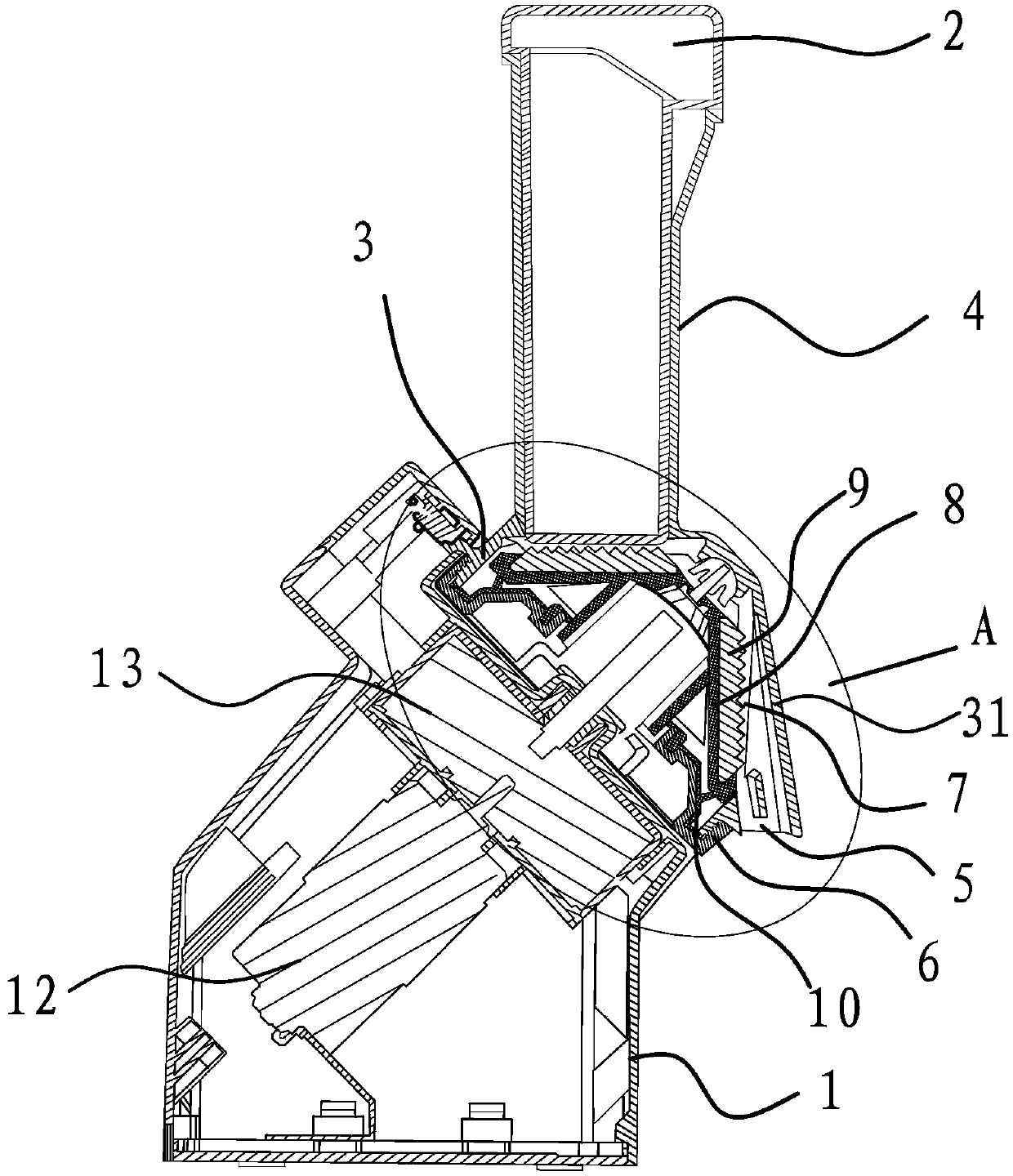

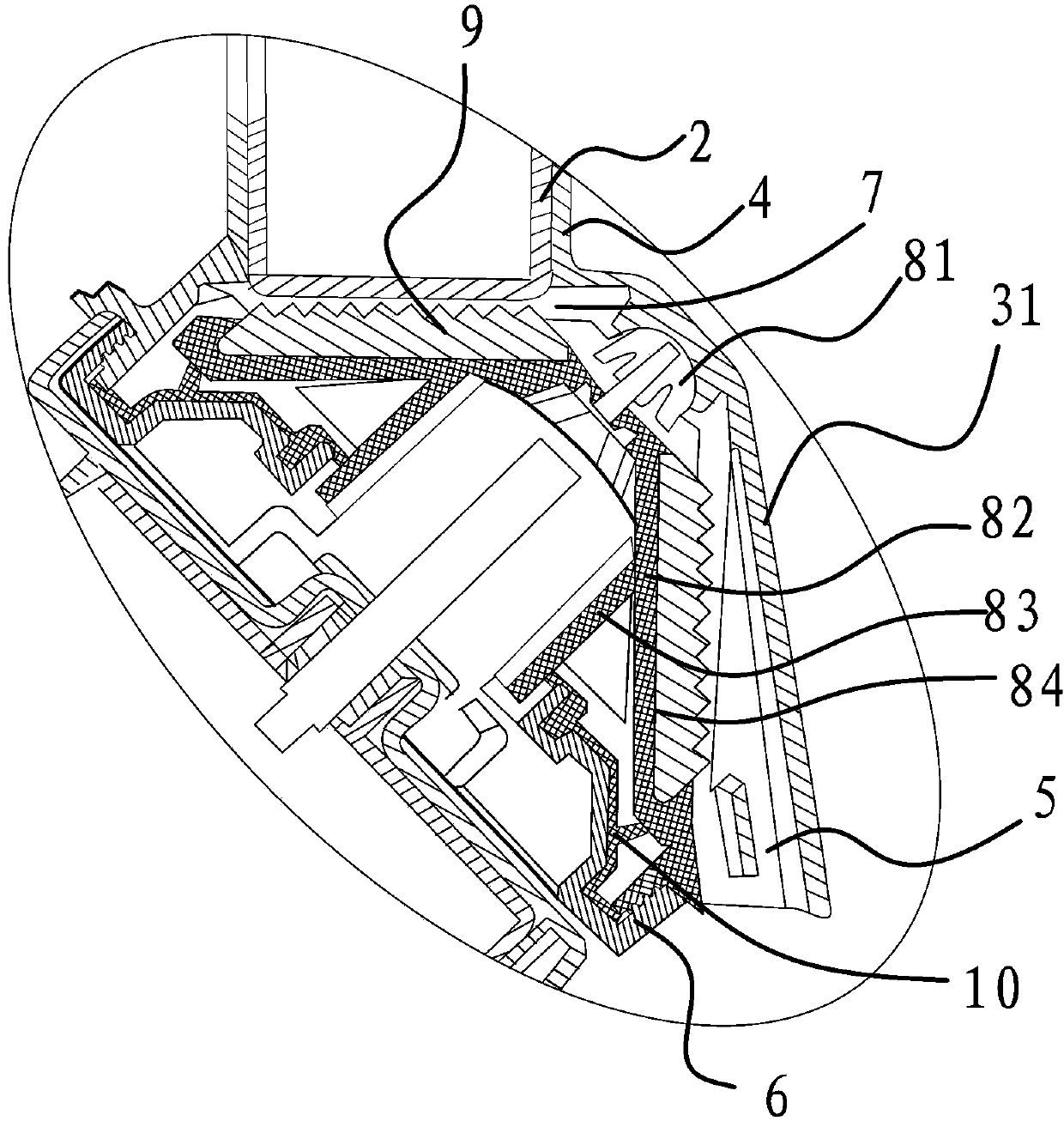

[0042] Such as figure 2 with image 3 As shown, the fruit ice cream machine also includes a conical grinding disc 8 on the top of the base 1, a motor 12 located in the base 1, the motor 12 is connected with the grinding disc 8 through a reducer 13, and the motor 12 It can drive the grinding disc 8 to rotate, and the grinding disc 8 is located in the stirring chamber 7. On the outer conical surface...

Embodiment 2

[0049] The content of embodiment 2 is basically the same as that of embodiment 1, except that the outer conical surface of the grinding disc 8 is provided with an arc-shaped installation groove 84, and the curvature of the arc is from the apex of the outer conical surface of the grinding disc 8 to the bottom. Gradually increasing, and the protruding direction of the arc shape is away from the direction of the corresponding straight generatrix. The blade 9 is bent into a corresponding shape and then plugged and fixed in the corresponding installation groove 84 .

Embodiment 3

[0051] The content of embodiment 3 is basically the same as embodiment 1, the difference is that, as Figure 5 As shown, the outer conical surface of the grinding disc 8 where the blade 9 is located and the groove bottom surface 86 of the raised part of the adjacent storage tank 85 have a strip-shaped step surface 88, and the strip-shaped stepped surface 88 is arc-shaped, and The curvature of the arc gradually increases from the apex of the outer conical surface of the grinding disc to the bottom, and the protruding direction of the arc is away from the corresponding straight generatrix. The frozen slag falls into the storage tank 85 after this blade 9 cuts the frozen fruit at present, and the frozen slag in the material storage tank 85 flows out along with the groove bottom surface 86 of inclination and at the discharge port 5, so it can be installed by the previous blade 9 The arc-shaped curved surface of the groove 84 is thrown out to improve the discharge speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com