Photovoltaic cell module

A photovoltaic cell and module technology, applied in the field of solar photovoltaic power generation, can solve the problems of unavoidable mutual charging and discharging of cells, consuming a lot of manpower, material resources and time, and affecting the reliability and life of battery packs, so as to improve the actual power generation capacity, The effect is obvious, the effect of improving the photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

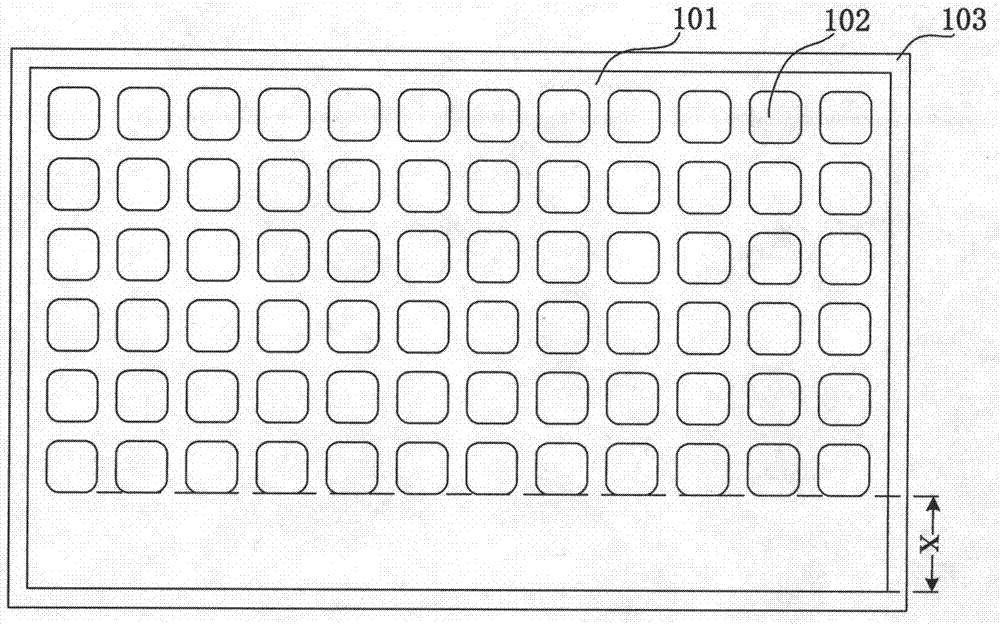

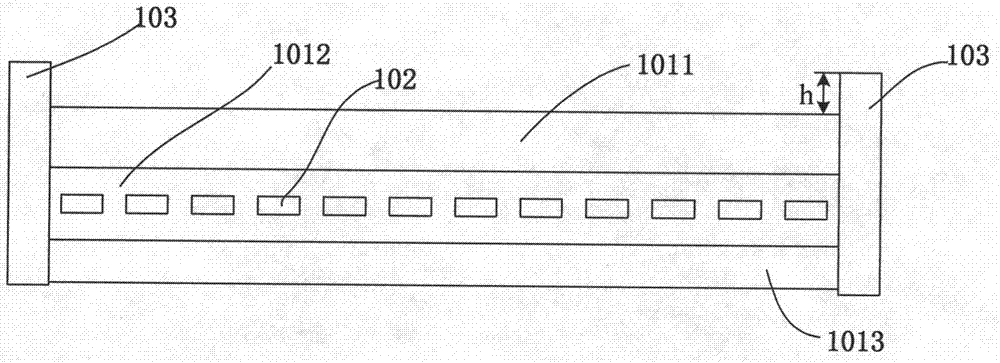

[0030] refer to figure 2 , image 3 The photovoltaic cell assembly provided in this embodiment includes: a substrate 101 , a plurality of photovoltaic cell sheets 102 on the substrate 101 , and a frame 103 disposed around the substrate 101 . The photovoltaic cells 102 may be monocrystalline silicon photovoltaic cells or polycrystalline silicon photovoltaic cells. The substrate 101 includes a transparent top surface layer 1011 , a sealing material 1012 and a back layer 1013 from top to bottom, and the plurality of photovoltaic cells 102 are located in the sealing material 1012 . The transparent top surface layer 1011 may be made of photovoltaic glass, the sealing material 1012 may be EVA (ethyl vinyl acetate, ethyl vinyl acetate), and the back layer 1013 may be Tedlar.

[0031] The plurality of photovoltaic cells 102 are arranged in an array on the substrate 101 , with 12 photovoltaic cells 102 in each row and 6 photovoltaic cells 102 in each column. Such as figure 2As sh...

Embodiment 2

[0037] Such as Figure 6 As shown, the photovoltaic cell assembly provided in this embodiment is similar to the first embodiment, including: a substrate 201 , a plurality of photovoltaic cell sheets 202 on the substrate 201 , and a frame 203 disposed around the substrate 201 . The plurality of photovoltaic cells 202 are arranged in an array on the substrate 201 . The difference from the first embodiment is that in this embodiment, each row has 6 photovoltaic cells 202 , and each column has 12 photovoltaic cells 202 .

[0038] Since the photovoltaic cell module of the present invention adopts an asymmetric design, it may be placed horizontally or vertically during actual installation. Considering different installation requirements, battery modules can be designed for horizontal and vertical installation respectively. Embodiment 1 is suitable for horizontal installation, and Embodiment 2 is for corresponding vertical installation.

Embodiment 3

[0040] Such as Figure 7 As shown, this embodiment provides another photovoltaic cell assembly, including: a substrate 301 , a plurality of photovoltaic cell sheets 302 located on the substrate 301 , and a frame 303 disposed around the substrate 301 . Wherein, the photovoltaic cells 302 may be monocrystalline silicon photovoltaic cells or polycrystalline silicon photovoltaic cells. The substrate 301 sequentially includes a transparent top surface layer, a sealing material and a back layer from top to bottom, and the plurality of photovoltaic cells 302 are located in the sealing material. The transparent top surface layer can be made of glass, the sealing material can be EVA (ethyl vinyl acetate, ethyl vinyl acetate), and the back layer can be Tedlar.

[0041] The plurality of photovoltaic cells 302 are arranged in an array on the substrate 301 , with 10 photovoltaic cells 302 in each row and 6 photovoltaic cells 302 in each column. Such as Figure 7 As shown, the shortest d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com