Steel ball intelligent automatic counting device and automatic counting method thereof

An automatic counting and steel ball technology, applied in the field of steel ball manufacturing, can solve the problems of waste, labor consumption, low counting efficiency, etc., and achieve the effects of improving production efficiency, reducing counting errors, and reducing waste of materials and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

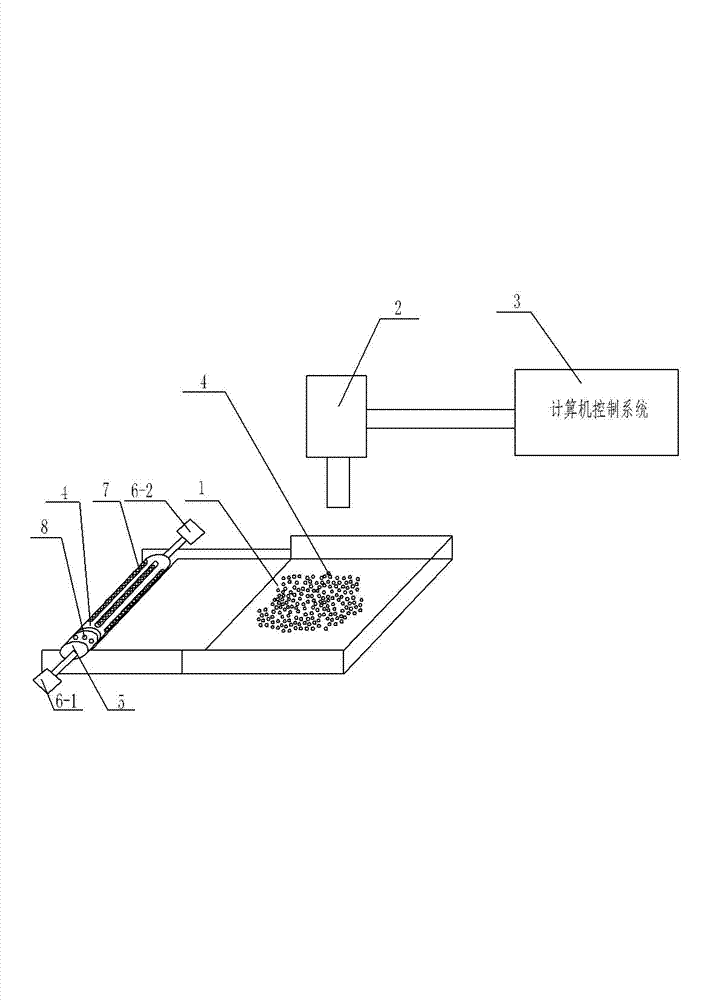

[0013] See figure 1 As shown, a steel ball intelligent automatic counting device includes a counting disc 1, an industrial camera 2 is arranged on the counting disc 1, the industrial camera 2 is connected to a computer control system 3, and the computer control system 3 collects on the counting disc 1 collected by the industrial camera. The steel balls are counted.

[0014] A feeding roller 4 and a compensation roller 5 are arranged at the entrance of the counting disc 1, and the feeding roller 4 and the compensation roller 5 are respectively connected with stepping motors 6-1 and 6-2, and a feeding groove 7 is arranged on the outer periphery of the feeding roller 4; The outer periphery of the roller 5 is provided with a storage single hole 8, which can only store one steel ball. The above-mentioned device constitutes a compensation device. In fact, there are other compensation devices in the prior art. Accurate counting of balls and satisfying the packing requirements of ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com