Pulse eddy current detection device and method for fatigue cracks of large mine vibrating screen

A pulsed eddy current and detection method technology, which is applied in the direction of material magnetic variables, can solve the problem of the probe reducing the detection accuracy, and achieve the effects of early warning and non-destructive online detection, suppression of signal noise, and large amount of information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

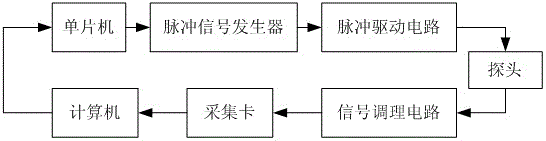

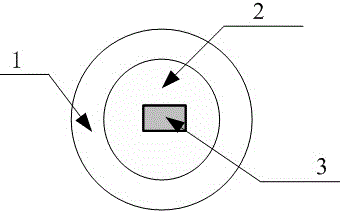

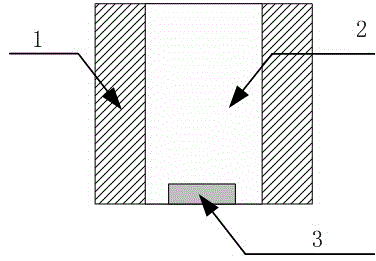

[0031] Embodiment 1: A pulsed eddy current detection device and method for fatigue cracks in a large mining vibrating screen, the device includes a single-chip microcomputer, a pulse signal generator, a pulse drive circuit, an eddy current probe, a signal conditioning circuit, an acquisition card and a computer; The output end of the single-chip microcomputer is connected with the input end of the pulse signal generator, the output end of the pulse signal generator is connected with the input end of the pulse driving circuit, the output end of the pulse driving circuit is connected with the input end of the eddy current probe, and the eddy current probe's The output end is connected with the input end of the signal conditioning circuit, the output end of the signal conditioning circuit is connected with the input end of the acquisition card, the output end of the acquisition card is connected with the input end of the computer, and the output end of the computer is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com