Intake apparatus for internal combustion engine

A technology of internal combustion engine and air suction device, applied in engine components, engine control, machine/engine, etc., can solve the problems of large ventilation resistance, reduced suction efficiency, and large suction noise, so as to reduce and avoid suction noise. Deterioration of acceleration performance and effect of preventing abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

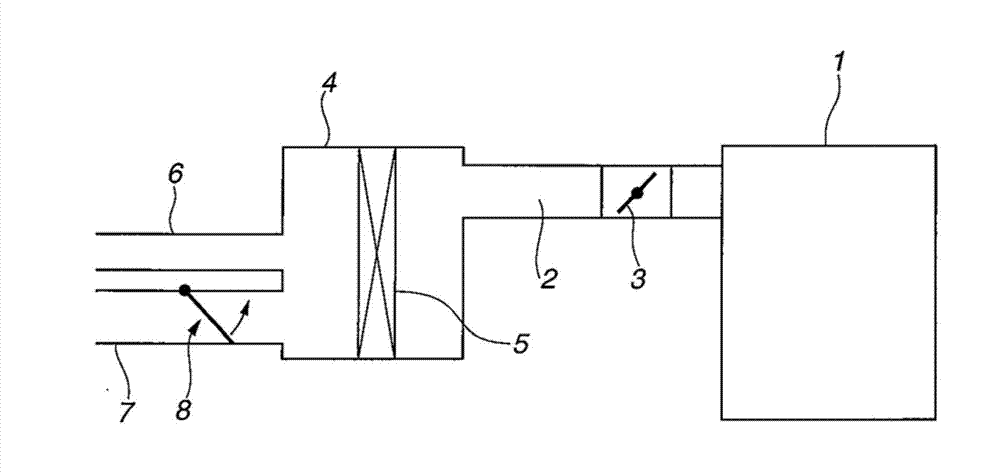

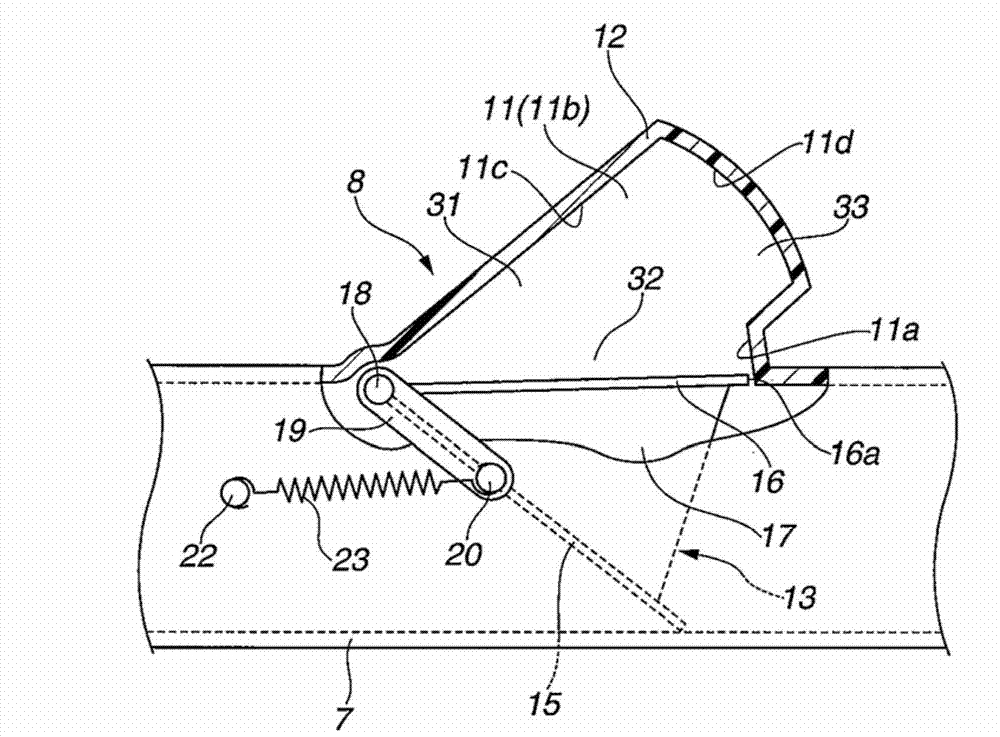

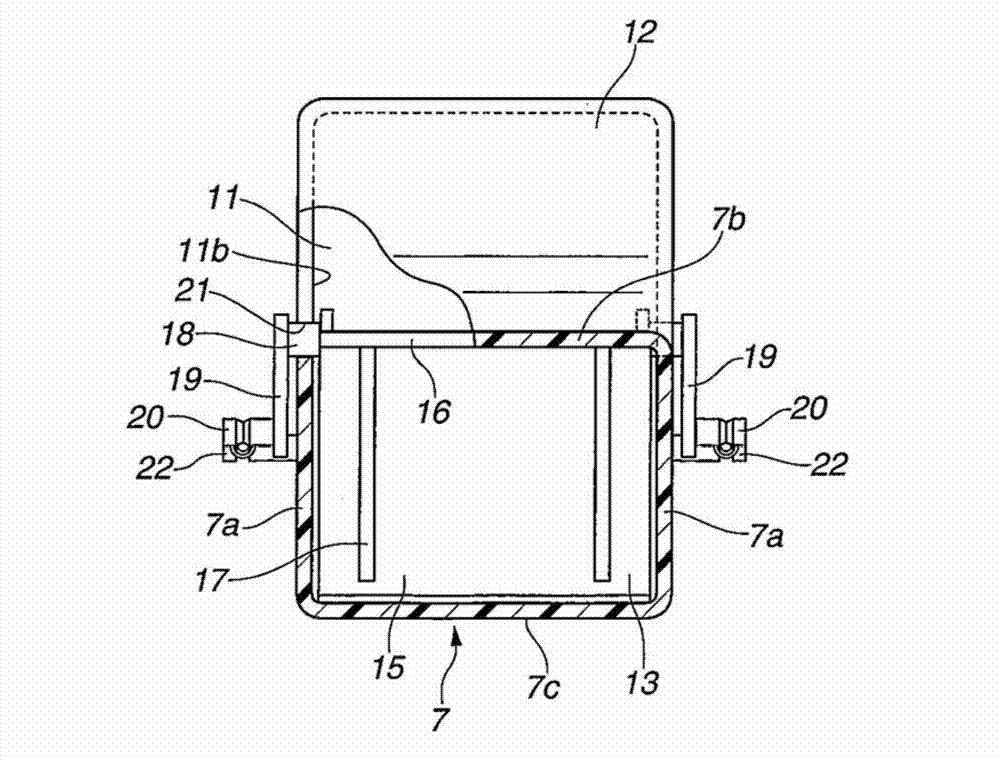

[0038] Hereinafter, an embodiment of the present invention will be described in detail based on the drawings. figure 1 It is a structural explanatory diagram schematically showing the overall structure of the air intake device of the internal combustion engine 1. For example, the air intake passage 2 connected to the air intake collector (not shown) of the internal combustion engine 1 formed by a gasoline engine is provided with a throttle. Valve 3, and the front end is connected to the air filter 4. The air cleaner 4 is divided into a so-called dust side and a clean side by an air cleaner element 5 inside, and a main air duct 6 and a sub air duct 7 serving as intake inlets are connected to the dust side. The main air duct 6 and the auxiliary air duct 7 are arranged in parallel with each other, and each front end is opened to the outside as an outside air inlet. And, one of them, for example, is provided in the sub-air duct 7 with a damper mechanism 8 for opening and closing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com