Skid-mounted pump set device

A skid-mounted pump set technology, which is applied in biochemical cleaning devices, enzymology/microbiology devices, bioreactor/fermentation tank combinations, etc., can solve the problems of low installation efficiency and large space occupation, and achieve the goal of occupying more space Small, the effect of increasing explosion-proof safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

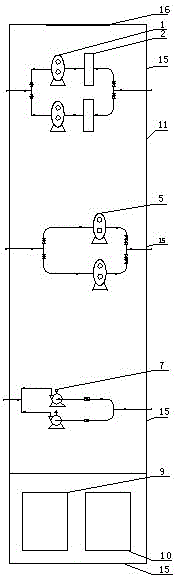

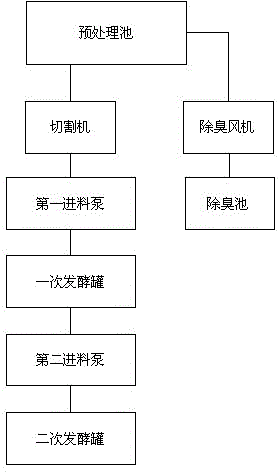

[0016] Embodiment 1: as figure 1 As shown, the skid-mounted pump unit device of this embodiment includes a housing 11 and a skid-mounted foundation. The housing 11 is equipped with a door 15 and a ventilation window 16. The housing 11 is equipped with an exhaust fan. The housing 11 is also provided with an electric control cabinet 9 and The instrument cabinet 10 is provided with a pump unit inside the shell 11, and the skid-mounted foundation is "I" steel, the pump unit is fixed on the "I" steel by bolts, and the skid-mounted foundation is fixed with lifting lugs. The pump group unit is a unit used for pretreatment and fermentation in the process, including two groups of cutting machines 2 and first feeding pumps 1 connected in parallel, and the first feeding pump 1 and cutting machine 2 in each group are connected in series, The shell 11 is also provided with two second feed pumps 5 connected in parallel, two deodorizing fans 7 connected in parallel, the electric control cabi...

Embodiment 2

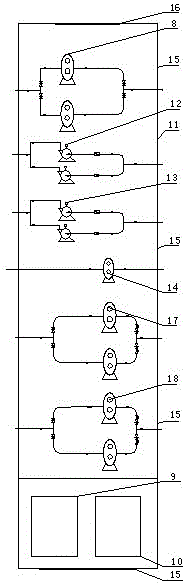

[0020] Embodiment 2: as image 3 As shown, a skid-mounted pump unit device includes a casing 11 and a skid-mounted foundation. The casing 11 is equipped with a door 15 and a ventilation window 16. The casing 11 is also provided with an electric control cabinet 9 and an instrument cabinet 10. The casing 11 There is a pump unit inside, the skid-mounted foundation is "I" steel, the pump unit is fixed on the "I" steel by bolts, and lifting lugs are fixed on the skid-mounted foundation. The pump unit is a unit used for desulfurization in the process, including two cooling water circulation pumps 8 connected in parallel, two air blowers 12 connected in parallel, two Roots blowers 13 connected in parallel, a hot water pump and two mutual Parallel hot water circulation pump 18. The hot water pump includes a small hot water pump 14 and two parallel large hot water pumps 17 .

[0021] In this embodiment, three or more cooling water circulation pumps 8 connected in parallel, three or m...

Embodiment 3

[0023] Embodiment 3: as Figure 4 As shown, a skid-mounted pump unit device includes a casing 11 and a skid-mounted foundation. The casing 11 is equipped with a door 15 and a ventilation window 16. The casing 11 is also provided with an electric control cabinet 9 and an instrument cabinet 10. The casing 11 There is a pump unit inside, the skid-mounted foundation is "I" steel, the pump unit is fixed on the "I" steel by bolts, and lifting lugs are fixed on the skid-mounted foundation. The pump unit is used for fire fighting in the process, including two parallel biogas slurry and residue pumps 3, one air compressor 4 and two parallel fire pumps 6.

[0024] In this embodiment, three or more biogas slurry and residue pumps 3 connected in parallel, two or more air compressors 4 connected in parallel, and three or more fire pumps 6 connected in parallel can also be installed in the pump unit. .

[0025] When in use, the biogas slurry and residue in the secondary fermentation tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com