Polylactic acid/stem grafting ethylene vinyl acetate (EVA)/imvite nano composite materials and preparation method thereof

A nanocomposite material and composite material technology, which is applied in the field of polylactic acid/grafted EVA/montmorillonite nanocomposite materials and their preparation, can solve the problems such as the inability to obtain exfoliated nanocomposite materials, and achieve excellent comprehensive performance and improved Effect of heat resistance and toughness increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

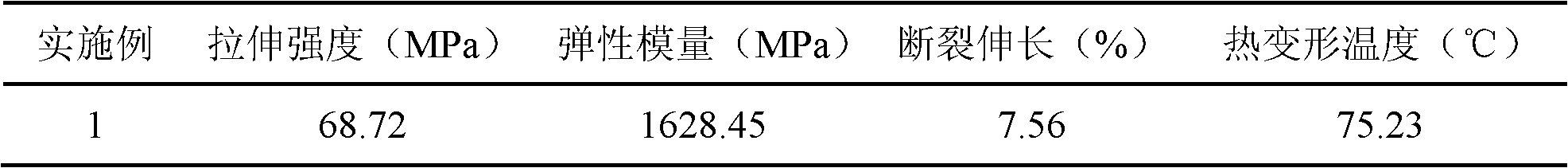

[0029] With 10 parts of 0.5% graft rate, the EVA of 10% vinyl acetate content, the modified montmorillonite of 1 part content 1% cetyltrimethylammonium bromide, extrude granulation with twin-screw, extrude The temperature is 150 ℃ ~ 195 ℃, the screw speed is 50 ~ 100rpm to obtain EVA / montmorillonite nanocomposite material; then 100 parts of polylactic acid and EVA / montmorillonite nanocomposite material are mixed evenly, and granulated by twin-screw extrusion. The extrusion temperature is 150°C-195°C, the screw speed is 50-100rpm, and the product is obtained, and its properties are shown in Table 1.

Embodiment 2

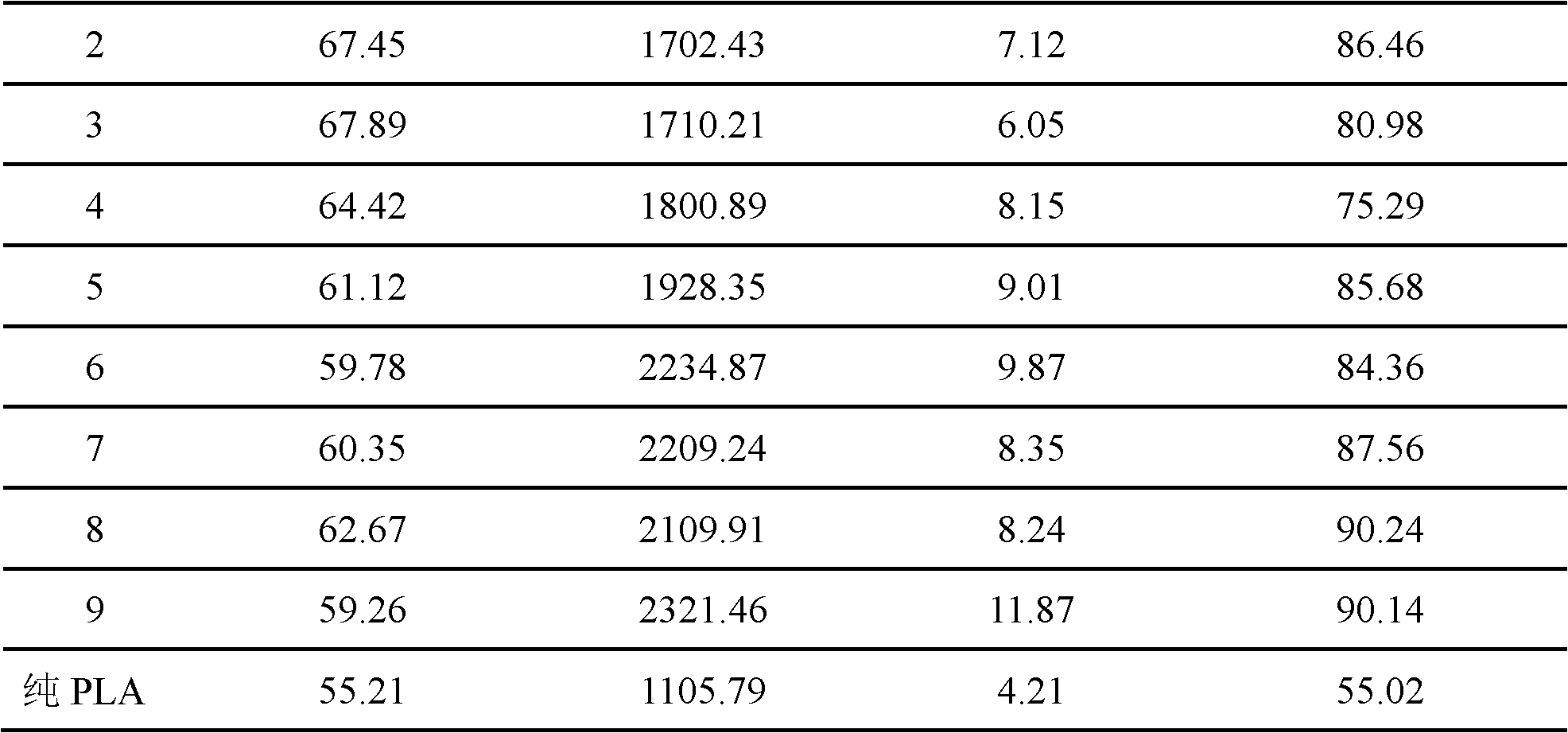

[0031] 15 parts of EVA with 0.6% grafting ratio, 20% vinyl acetate content, 2 parts of montmorillonite modified with 3% cetyltrimethylammonium chloride, granulated by twin-screw extrusion, extruded The temperature is 150°C-195°C, the screw speed is 50-100rpm to obtain the EVA / montmorillonite nanocomposite material; then 100 parts of polylactic acid and EVA montmorillonite nanocomposite material are mixed uniformly, extruded with twin-screw to granulate, extruded The outlet temperature is 150°C-195°C, the screw speed is 50-100rpm, and the product is obtained, and its properties are shown in Table 1.

Embodiment 3

[0033] 20 parts of EVA with 0.8% grafting rate, 30% vinyl acetate content, 2 parts of montmorillonite modified with 4% octadecyltrimethylammonium bromide, granulated by twin-screw extrusion, extruded The temperature is 150 ℃ ~ 195 ℃, the screw speed is 50 ~ 100rpm to obtain the modified EVA / montmorillonite nanocomposite material; then 100 parts of polylactic acid and EVA / montmorillonite nanocomposite material are mixed evenly, and produced by twin-screw extrusion pellets, the extrusion temperature is 150°C-195°C, the screw speed is 50-100rpm, and the product is obtained, and its properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com