Resin casting body processing die

A technology for processing molds and resin casting, which is used in the field of molds for making resin casting bodies, can solve the problems of difficult unloading of brittle resin casting bodies, uneven upper surface of casting bodies, large dimensional tolerances, etc. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in more detail below with examples in conjunction with the drawings.

[0020] The resin cast body mold of the present invention is composed of at least two double cross components, Figure 4 , 5 Shown is a resin cast body mold composed of four double cross components mismatched, and the bottom is sealed with transparent tape.

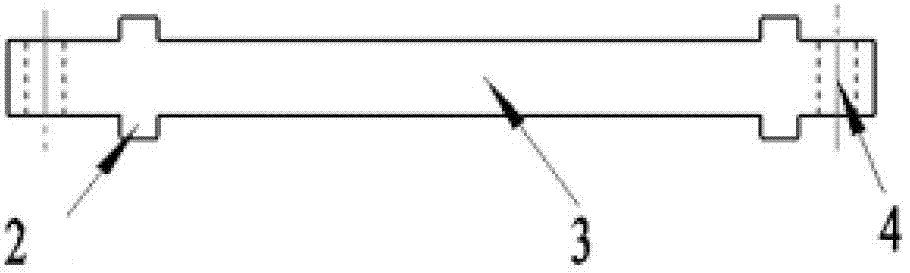

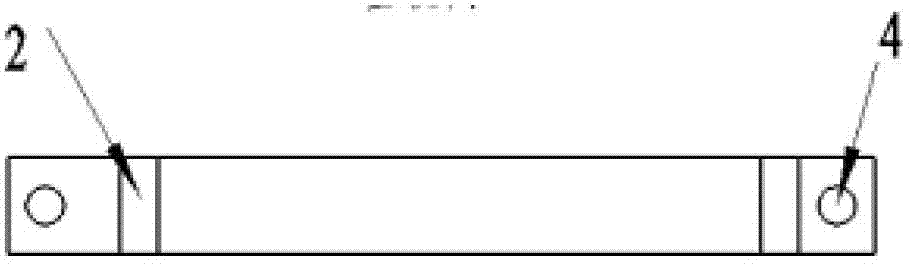

[0021] Combine Figure 1-Figure 3 , The double cross assembly 1 includes two short beams 2, a through beam 3, the length of the short beam 2 is twice the thickness of the bending spline of the resin casting body to be prepared plus the width of the through beam, and the distance between the short beams is the resin casting The length of the body bending spline plus the width of the short beam, and the thickness of the short beam is the width of the resin cast body bending spline. The thickness of the through beam 3 is the width of the prepared casting body. Each end of the through beam has a through hole 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com