Thermal forming closing-in device

A closing device and thermoforming technology, used in forming tools, engine components, metal processing equipment, etc., can solve problems such as the inner wall support of difficult workpieces, and achieve the effect of ensuring consistency, improving processing efficiency, and ensuring closing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

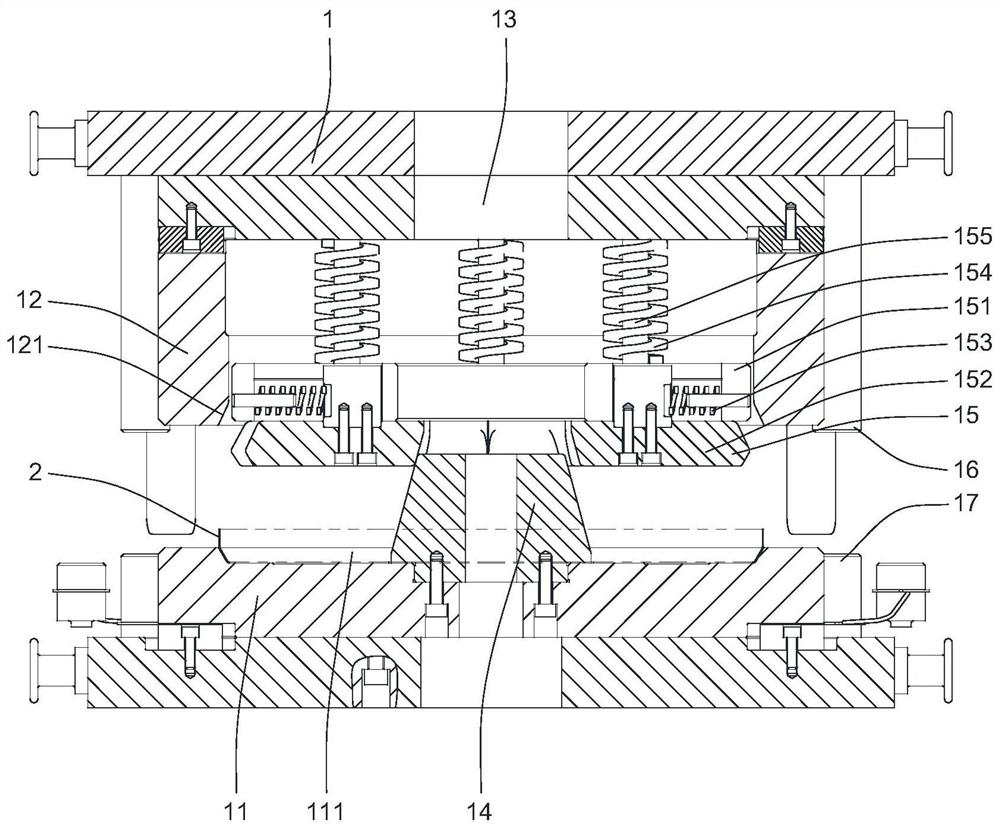

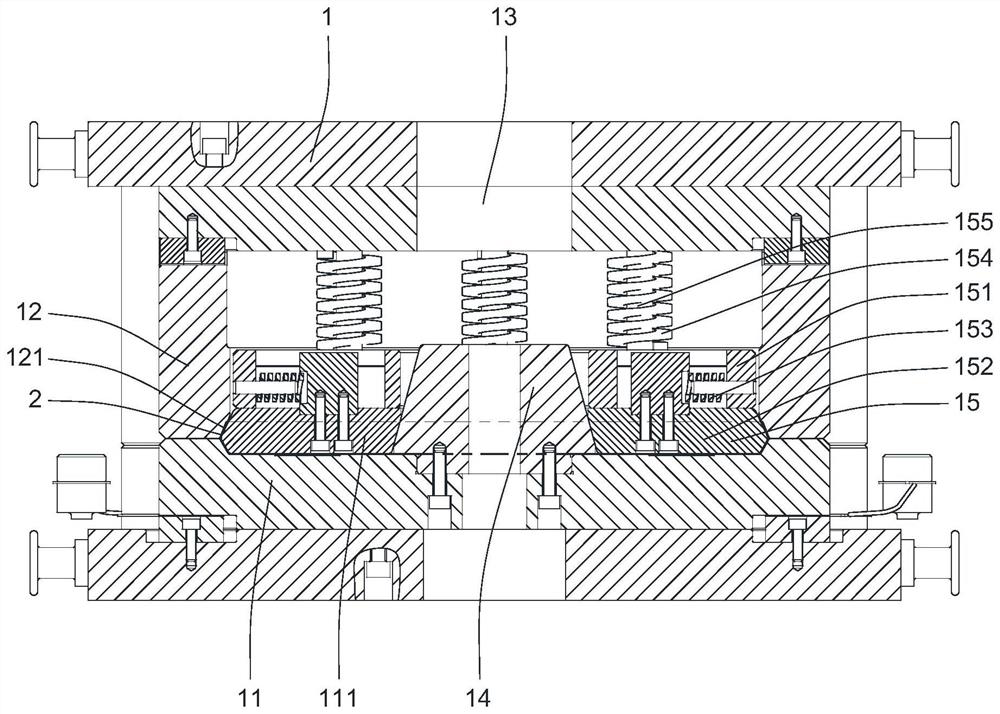

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

[0029] Figure 2 to Figure 7 Together, it shows the thermoforming closing device provided by the embodiment of the present invention, which is used to close the workpiece under high temperature, and can automatically support the inner wall of the workpiece and automatically withdraw the workpiece, effectively ensure the safety of the operator, improve the processing efficiency, and ensure the closing precision.

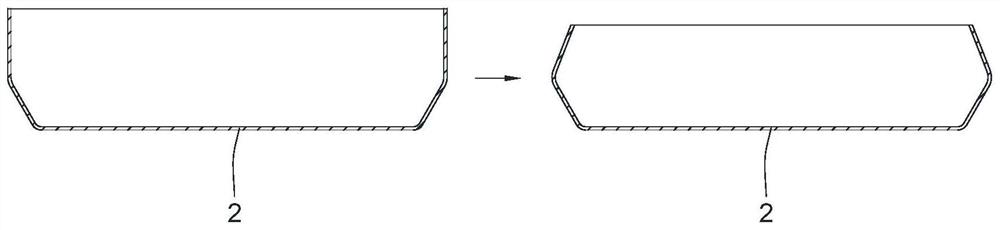

[0030] exist figure 1 shows a kind of closing change process of the workpiece 2 suitable for the thermoforming closing device, the thickness of the workpiece 2 is 0.8mm, and the material is martensitic stainless steel. Since the material has a large rebound when forming, the shape is not easy Control, in order to control the springback of the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com