Fuel preparation mold for solid fuel ramjet

A technology for ramjet and fuel preparation, which is applied in the direction of machines/engines, rocket engine devices, presses, etc., can solve the problems of lack of literature reports on solid fuel molds, and achieve the effects of ingenious design, easy mold removal, and raw material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

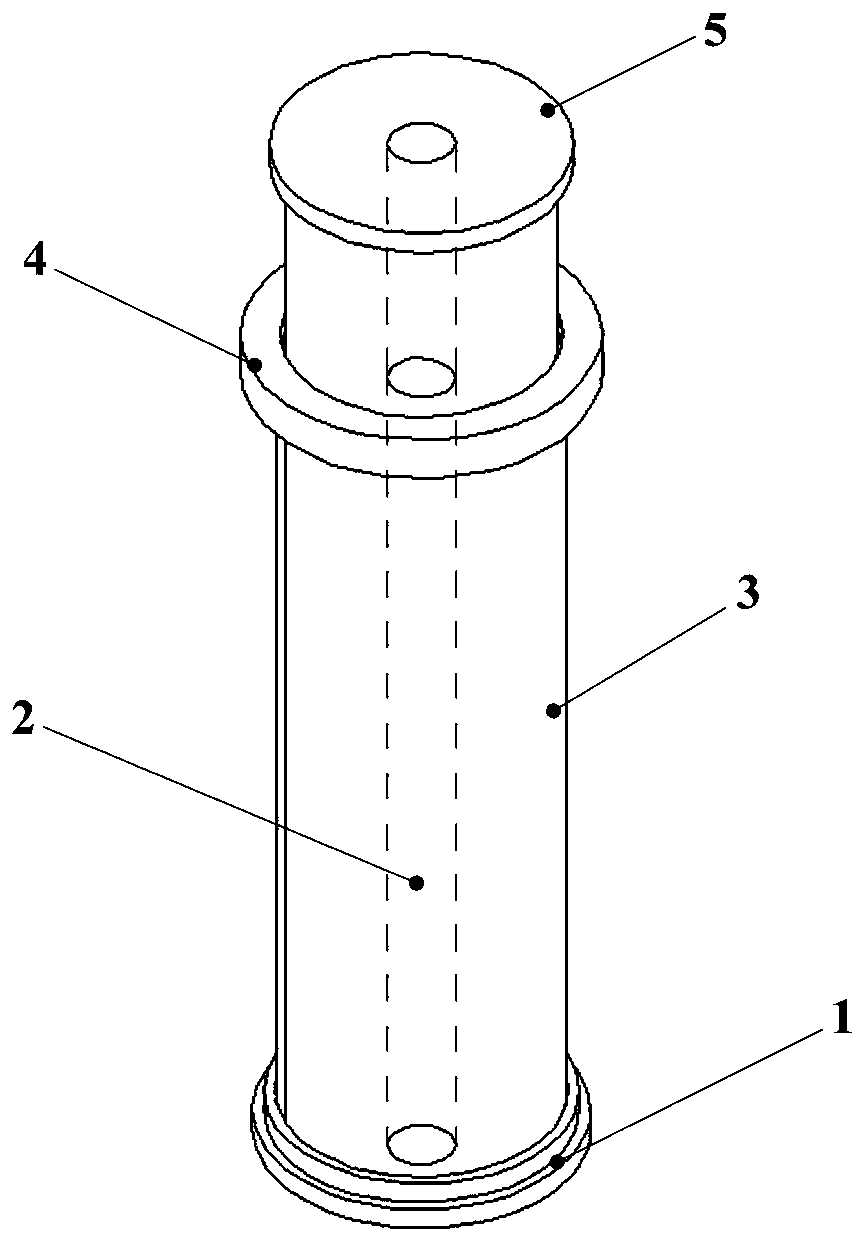

[0017] The mold cylinder body of the present invention includes two semi-cylindrical sections, which are connected through the gap fit of the slot; the base and the top snap ring are used to fix the two semi-cylindrical cylinder bodies of the mold. When ejecting the mold, you only need to remove the top snap ring, and then the mold barrel can be opened to facilitate the removal of solid fuel.

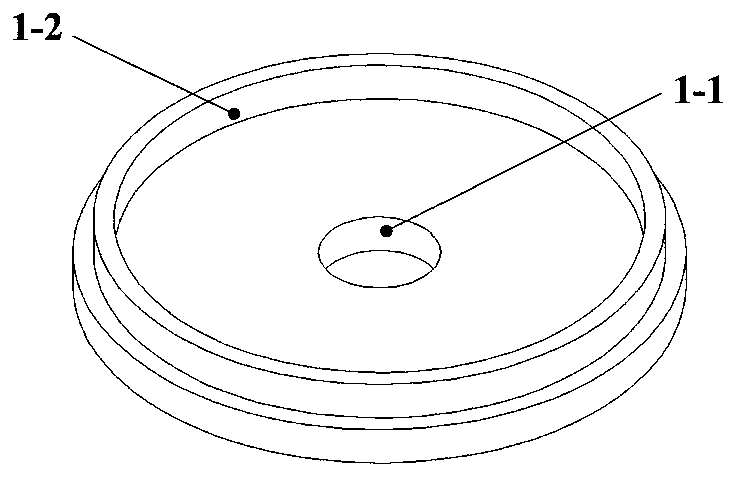

[0018] The solid fuel ramjet fuel preparation mold includes a base, a hollow heating pipe, a mold cylinder body, a top snap ring, and a compression block.

[0019] In the solid fuel ramjet fuel preparation mold, the base is connected with the hollow heating tube through an interference fit through a stepped hole; the outer surface of the lower end of the cylinder is connected with the stepped inner circle of the base through an interference fit, and the outer surface of the upper end of the cylinder is connected with the top snap ring through a stepped hole Interference fit; the inner h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com