Preparation method of high-protein and low-fiber biological nutrition maize straw forage grass

A straw biological and nutritional technology, applied in animal feed, animal feed, application, etc., can solve the problems of affecting livestock feed intake and digestion and absorption, high lignin and crude fiber content, limited high-quality green feed, etc., to achieve suitable for intensification The effect of production, high nutritional value, and reasonable strain design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following examples illustrate the preparation method of straw bio-nutritional forage grass of the present invention, but do not limit the scope of the present invention in any way.

[0039] one. Raw material preparation:

[0040]1. Choose well-preserved dry corn stalks without mold and deterioration (moisture content is 15% to 25%), and set aside.

[0041] 2. Use a straw rubbing machine or a straw crushing machine to rub and crush the dry corn stalks into finely divided materials of 1 to 3 cm.

[0042] 3. The processed dry corn stalk fine material is input into the winnowing machine for separation. After winnowing, the separation ratio of the skin and leaves is about 3:7.

[0043] 4. About 30% of the hard fiber of the outer skin is used for the utilization of corresponding industrial products, and about 70% of the separated leaves are used for the production of "high protein and low fiber straw nutritional biological forage".

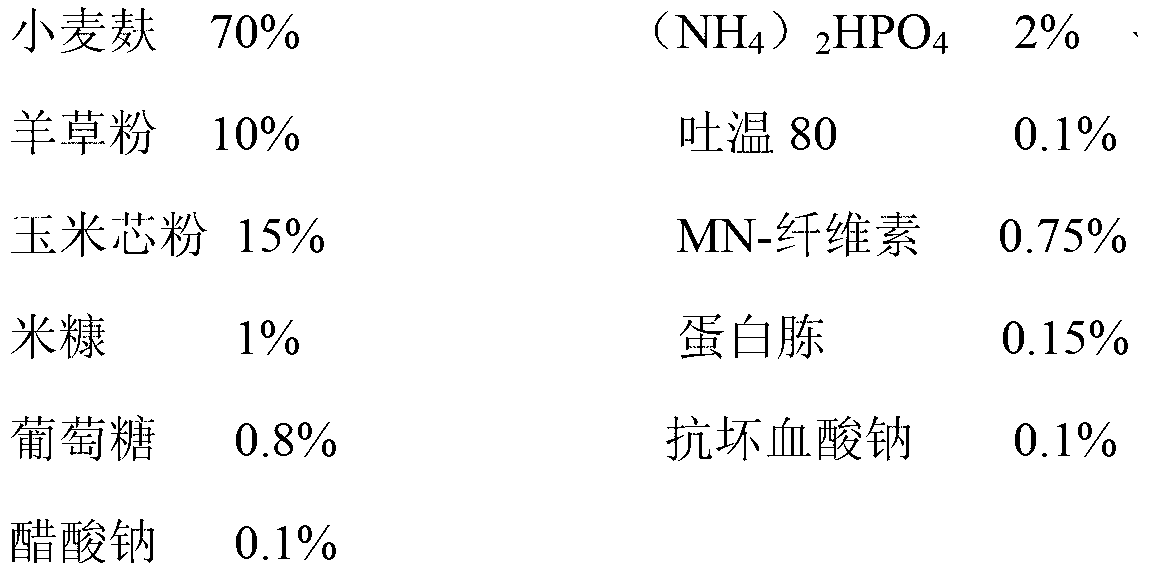

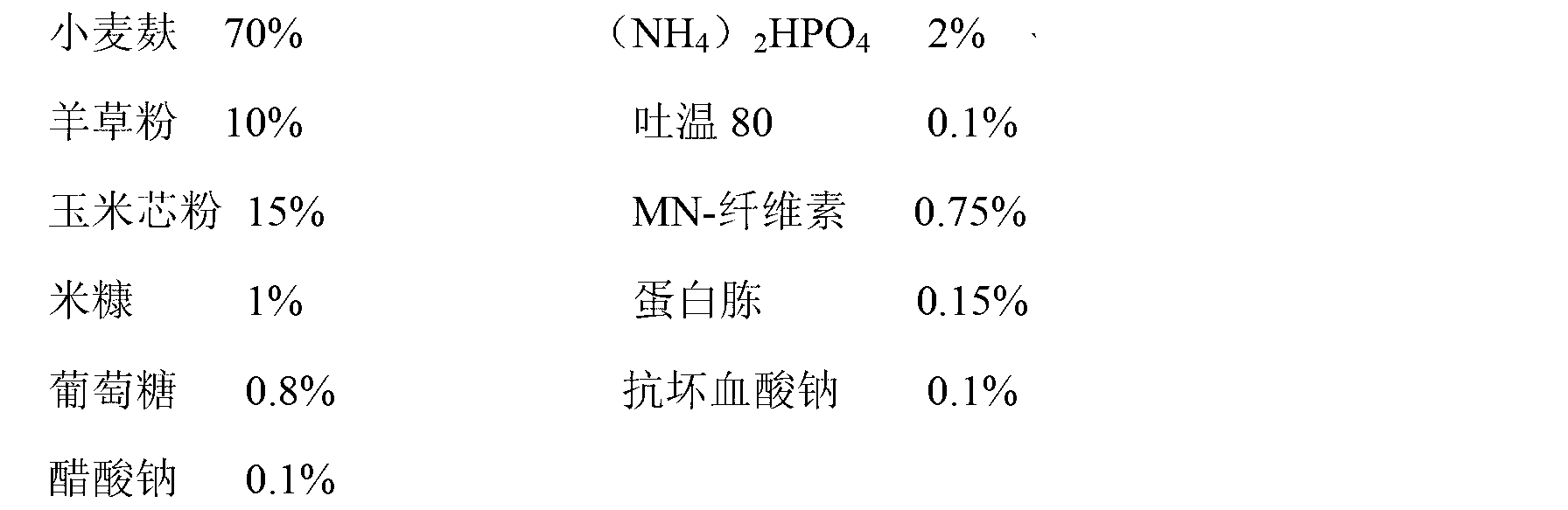

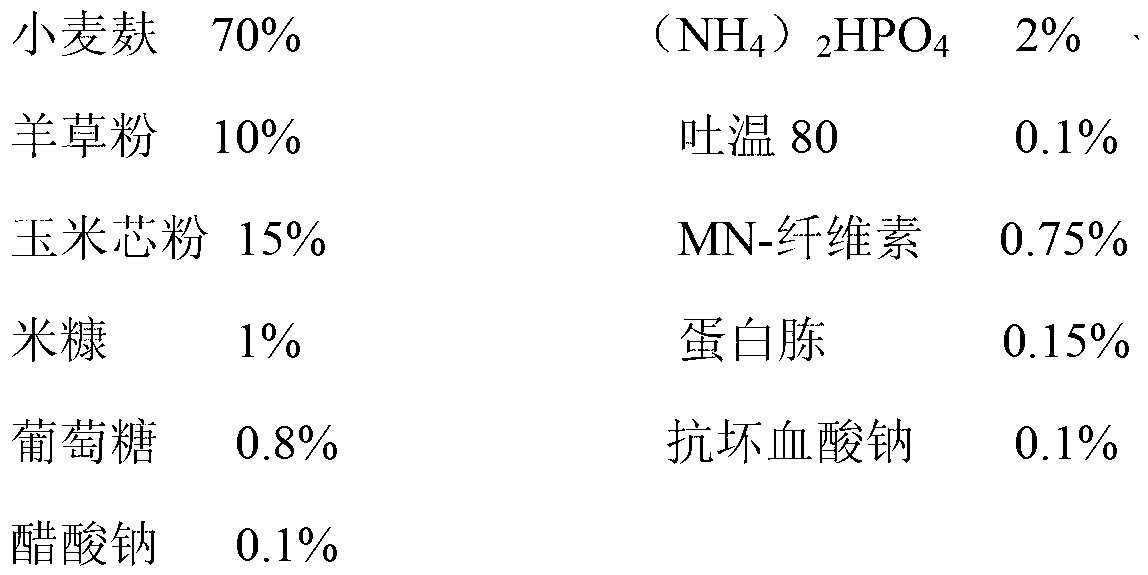

[0044] two. Preparation of nutrit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com