Completely-sealed and complete-solid insulation ring main unit

An all-solid, insulating ring technology, applied in the field of transmission and distribution electrical equipment, can solve the problem of ring main unit being easily damaged and achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

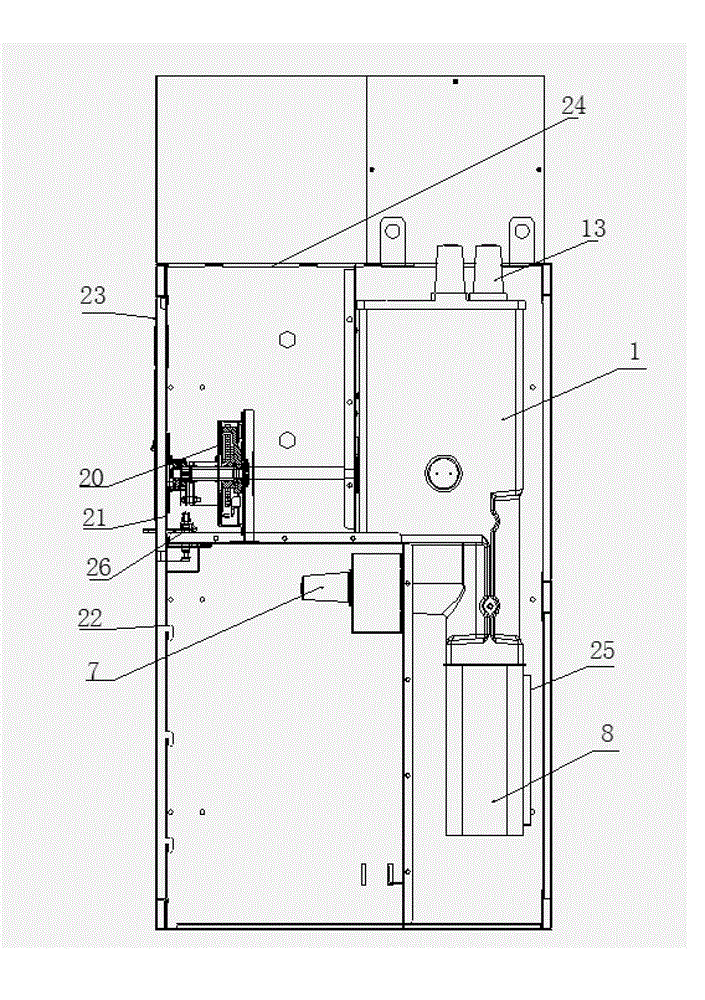

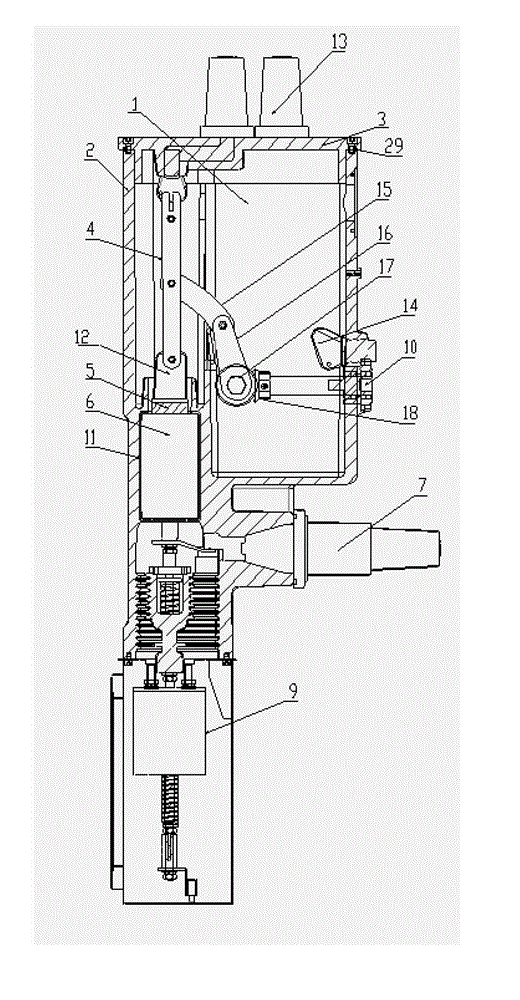

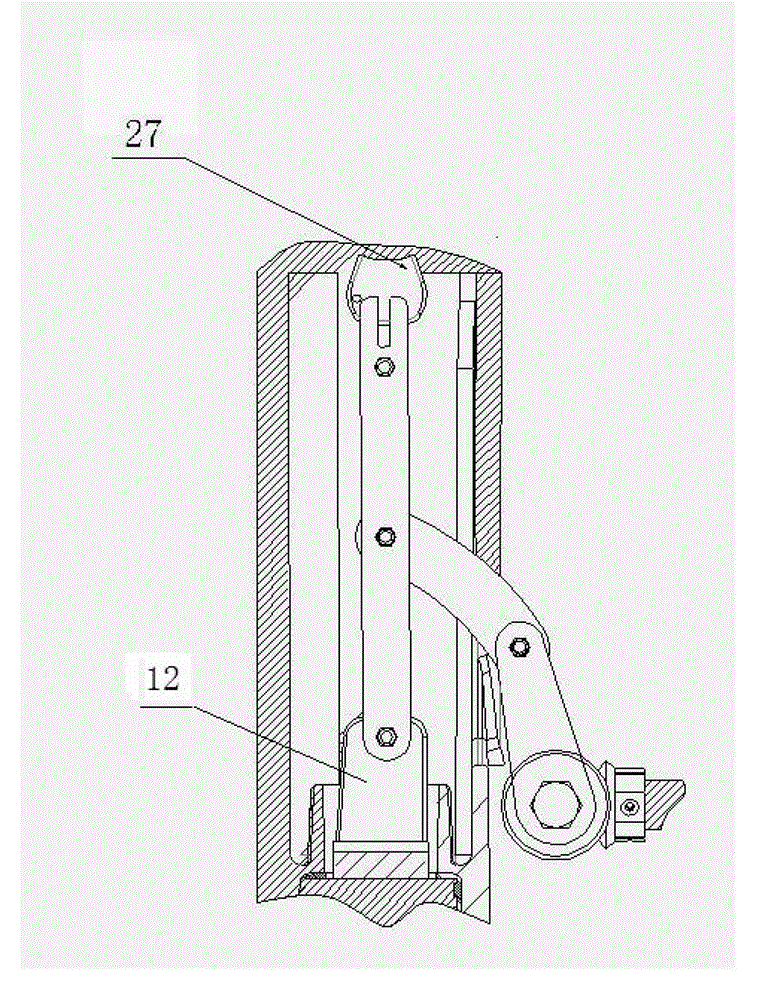

[0031] like figure 1 , 2 , 3, the circuit breaker body of the present invention includes the body 2, the upper cover 3 and the isolation grounding switch 27 installed inside, the upper outlet seat 5, the vacuum interrupter 6, the outlet bushing 7, the operation box 1 and the circuit breaker operation Institution 9 etc. The upper outlet seat 5, the vacuum interrupter 6, and the shielding cover 11 are cast longitudinally inside the body 2 at the same time, and each phase is separately set up as a compartment, and the static end of the vacuum interrupter 6 is fixed with a moving contact support frame 12 facing upwards. The moving contact 4 of each phase is in the form of two blades, which are respectively fixed on the two surfaces of the moving contact support frame 12. The two ends of the fixing screw adopt a stacked spring to provide contact pressure, and the moving contact 4 can rotate around this fixed point. The static contact of the isolating grounding switch 27 is molded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com