Generator stator end winding degradation diagnosis method based on correlation analysis of electrical quantities and mechanical quantities

A generator stator and stator winding technology, applied to measuring devices, using wave/particle radiation, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problem of low sampling rate, poor practicability, unsatisfactory sensitivity and reliability and other problems, to achieve the effect of high reliability and sensitivity, high detection value and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

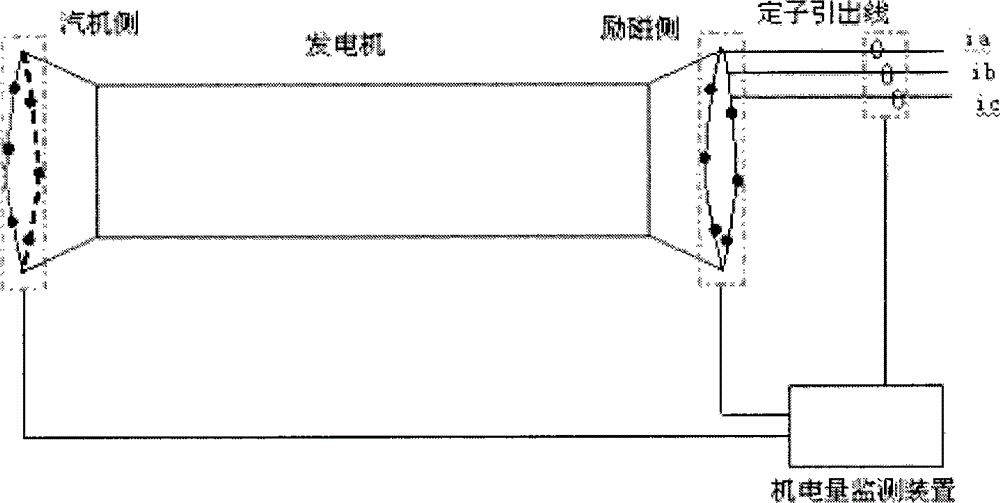

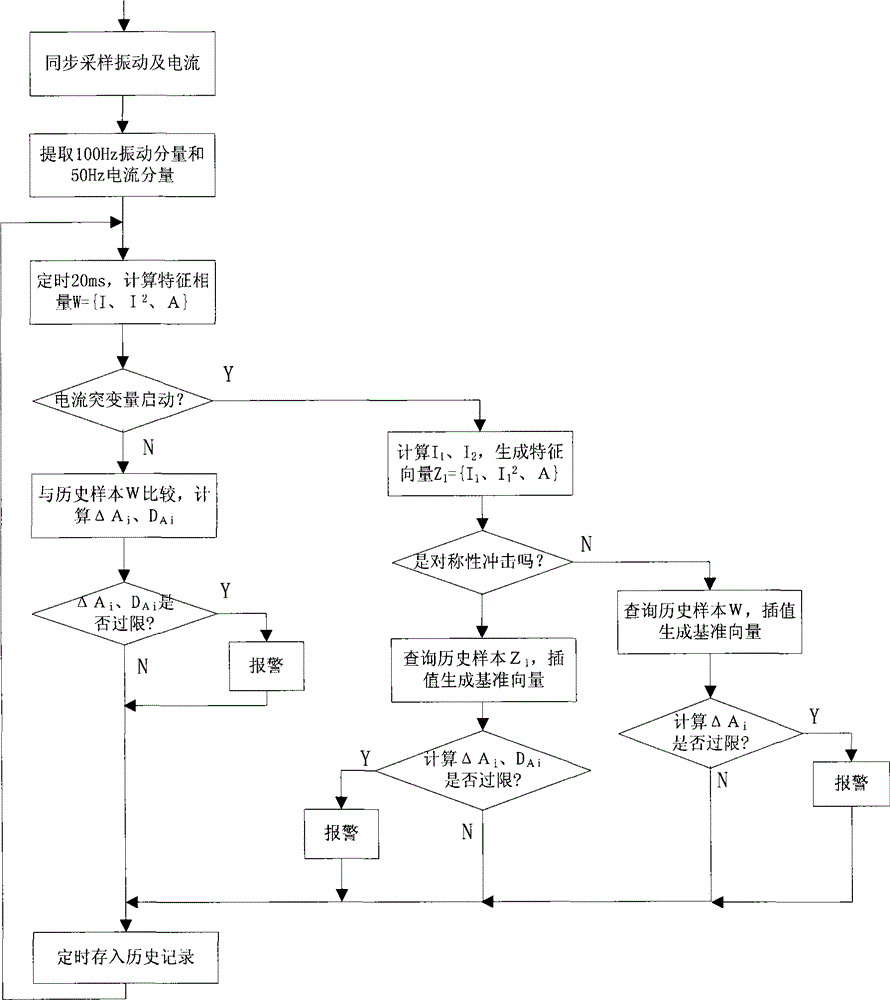

[0045] Vibration sensors are installed on the excitation side of the generator stator end and the turbine side winding, and optical fiber sensors are used; the three-phase current of the generator stator winding is measured by the generator stator three-phase current transformer. The measurement device uses a 3.6kHz sampling rate to collect vibration signals and current signals synchronously; the measurement device completes characteristic value calculation, logic discrimination and alarm, and sample data storage, according to image 3 Complete data processing. The measurement device is connected to the monitoring master station through Ethernet, uploads the collected and calculated vibration and current data to the master station, and the monitoring master station realizes human-computer interaction and system maintenance and management.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sampling rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com