Fully-enclosed assembled string structural system and construction method thereof

A prefabricated, fully enclosed technology, applied in the direction of the arched structure, dome roof structure, building components, etc., can solve the problems of increasing the applicable span, reduce the overall cost, facilitate transportation, improve sealing performance and waterproof performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

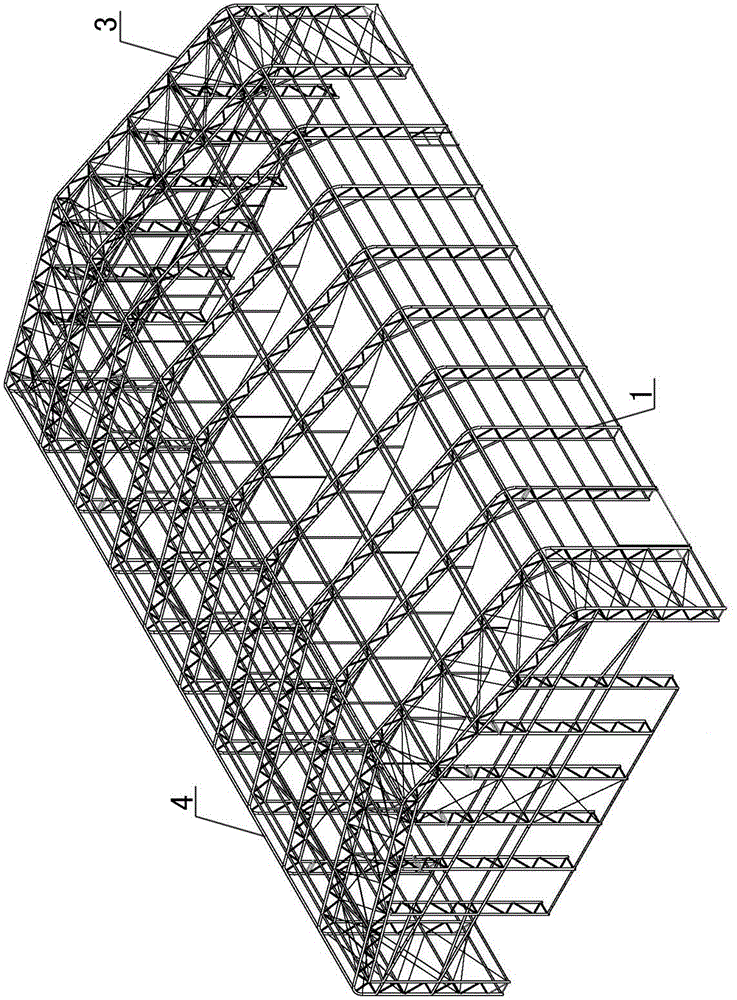

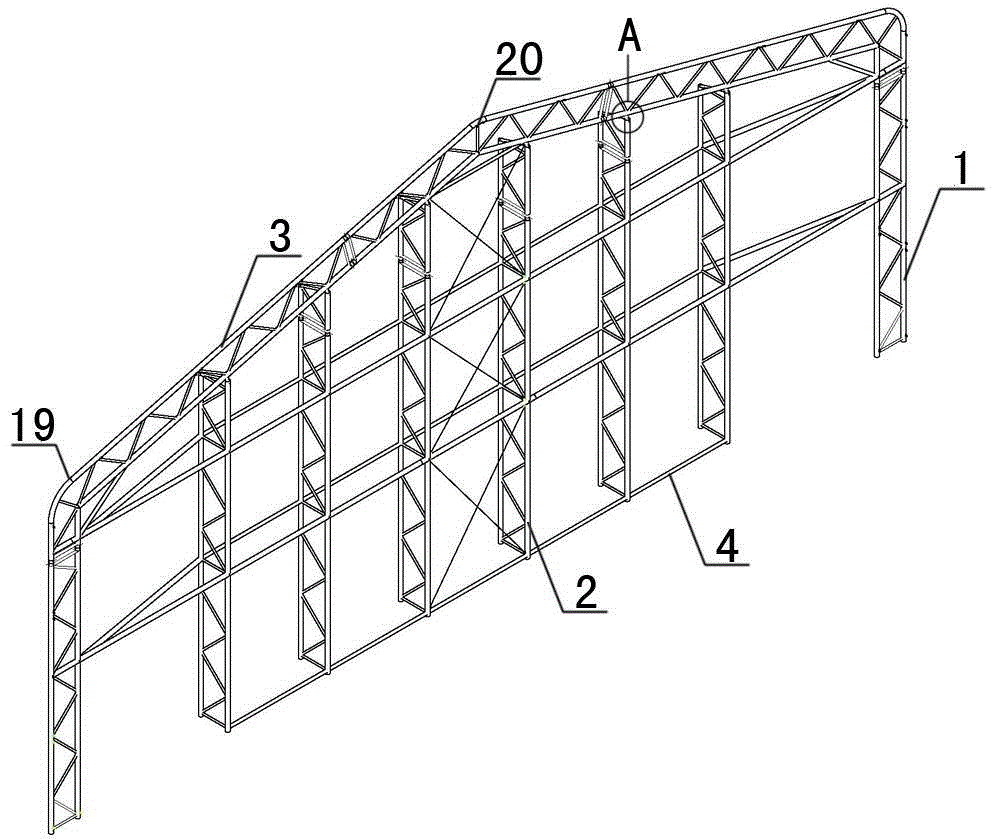

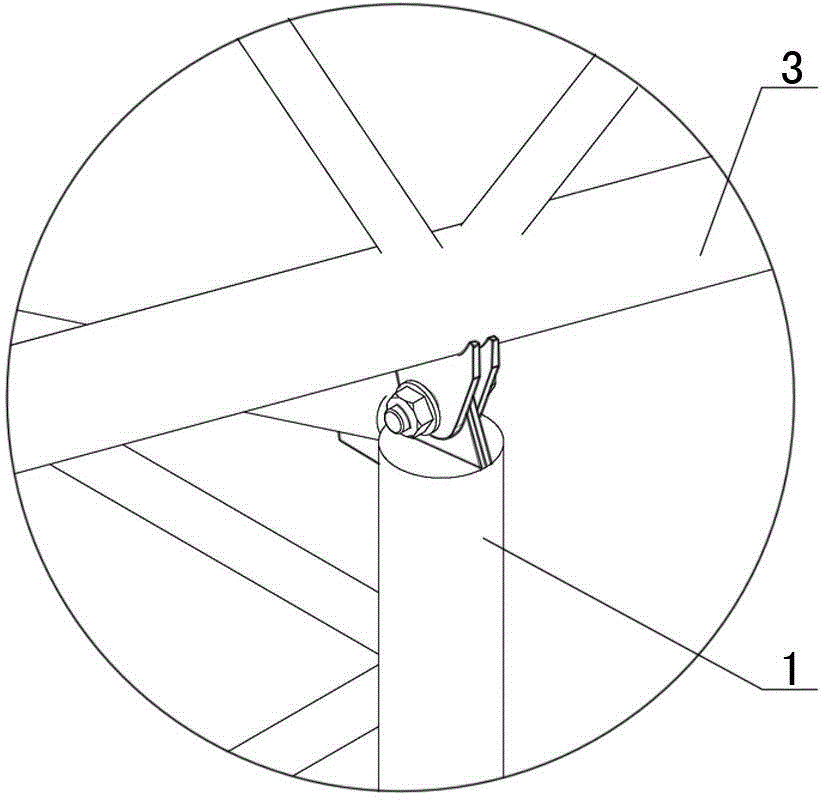

[0047]Examples see figure 1 As shown, this fully enclosed assembly string tension structure system includes a load-bearing structure and an enclosure structure. The load-bearing structure is a light steel skeleton including steel beams and steel columns, and the steel beams of the light steel skeleton are lattice double bars Truss steel beam 3, the steel column of the light steel skeleton is a lattice type double-rod truss steel column 1, and the double pole between the lattice type double-rod truss steel beam 3 and the lattice type double-rod truss steel column 1 Connect the web members, the lattice double-bar truss steel beam 3 and the lattice double-bar truss steel column 1 are connected by flanges and bolts 2 to form a door-shaped lattice double-bar truss steel beam-column, and the multi-door lattice The double-bar truss steel beams and columns are arranged in parallel, at intervals, and symmetrically along the long axis of the structural system, and the horizontal connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com