Heating furnace temperature decision-making method based on billet optimizing heating curve

A technology of heating curve and decision-making method, which is applied in the field of mathematical model development of heating furnace and optimal control of heating furnace, which can solve the problem of affecting the control effect of heating furnace, the inability to reasonably realize the optimal control of heating furnace and the purpose of energy saving and consumption reduction, and the lack of perfect consideration of heating Furnace energy consumption Steel slab intermediate temperature rise and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

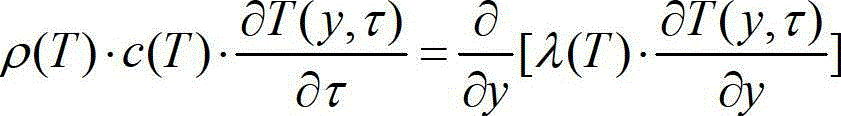

Method used

Image

Examples

Embodiment

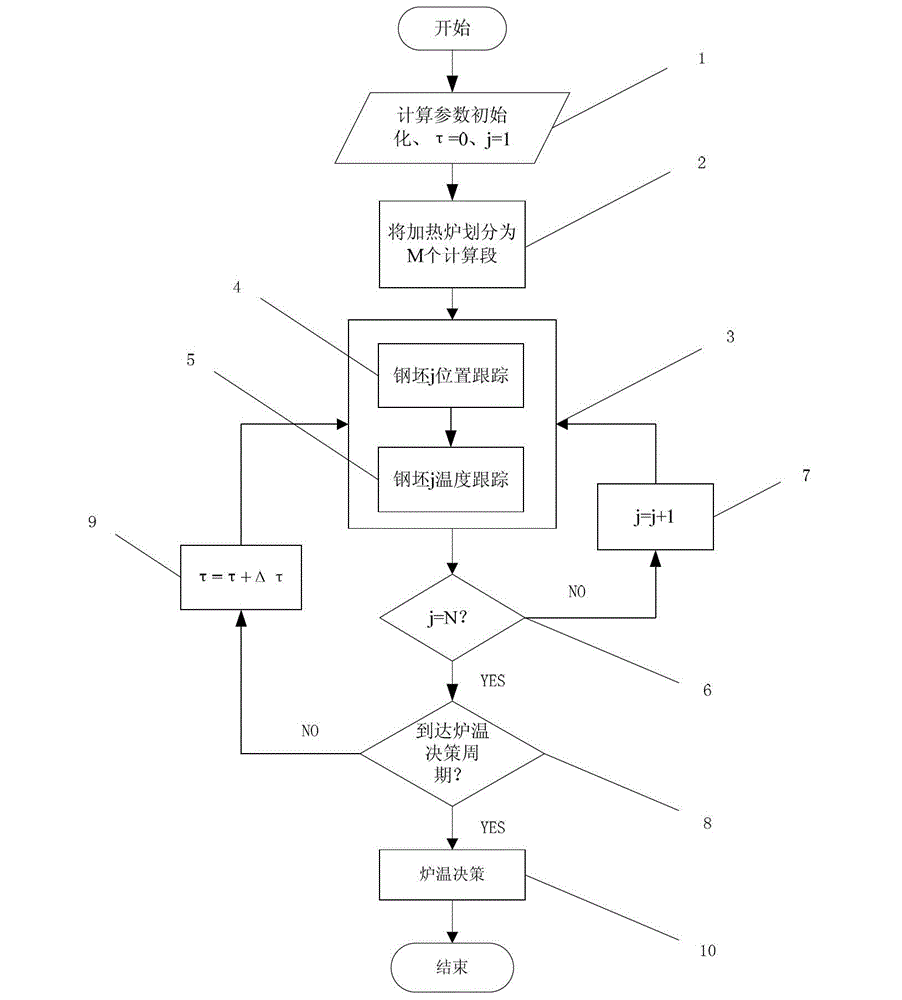

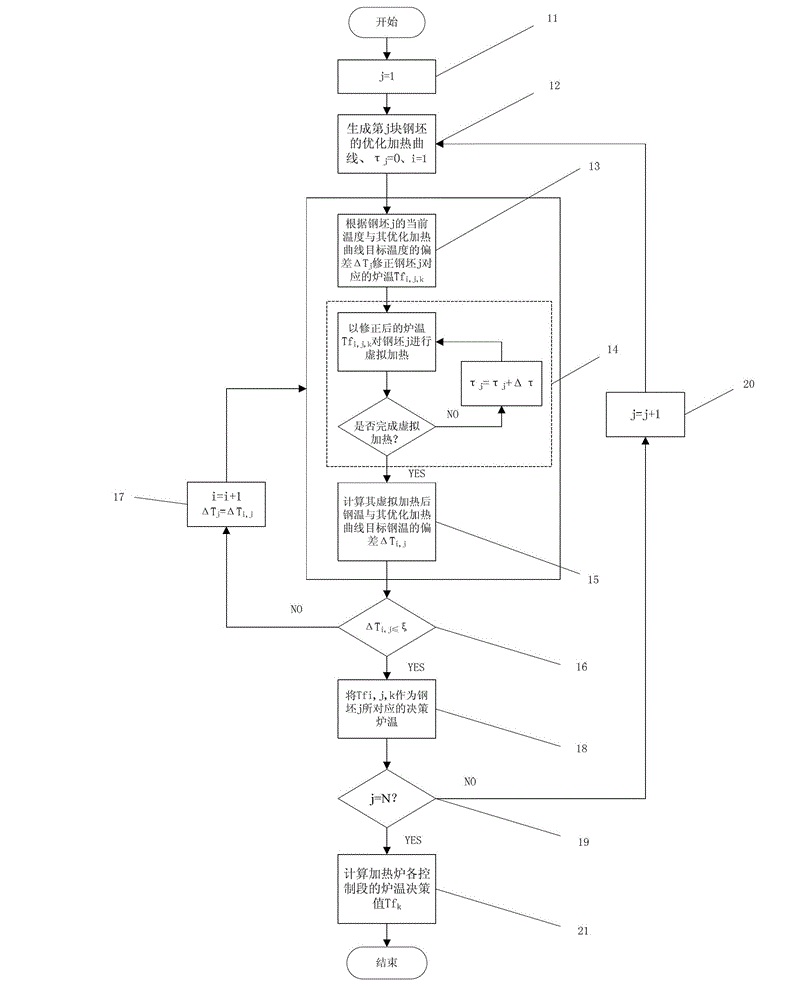

[0113] A heating furnace includes: heating stage 1, heating stage 2, heating stage 3, and soaking stage. The total length of the heating furnace is 50.5m. According to the method provided by the present invention, one section of heating is divided into 2 calculation sections, the second section of heating is divided into 3 calculation sections, the third section of heating is divided into 3 calculation sections, and the soaking section is divided into 2 calculation sections. The furnace section itself is used as three calculation sections, that is, the number of calculation sections is M=10.

[0114] The initial furnace temperature of each furnace section of the heating furnace is shown in Table 1.

[0115] Table 1 Initial furnace temperature of each furnace section

[0116] furnace section heating for a period Heating stage two Heating three stages soaking section Furnace temperature (℃) 1017 1043 1136 1193

[0117] The initial parameter infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com