Method for regenerating and extracting waste mineral oil by filling nitrogen extracting

A technology of waste mineral oil and extraction method, which is applied in the direction of lubricating composition, only multi-stage serial refining process, etc., and can solve the problems of serious secondary pollution and low quality of regenerated oil products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

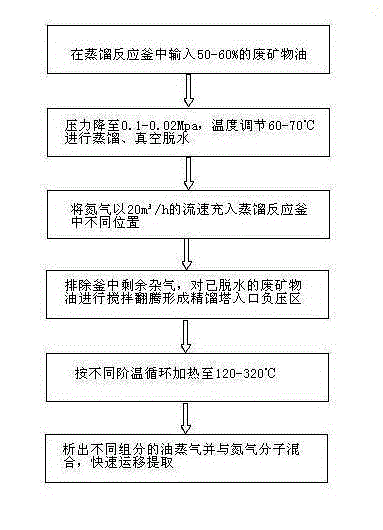

[0013] The waste mineral oil regeneration method of the present invention: firstly, input the pretreated waste mineral oil into the distillation reaction kettle to reach 50-60% of the volume of the kettle, close the oil inlet valve, and open the vacuum system after adding the distillation auxiliary agent, and the system takes about 30 minutes The pressure drops to -0.1-0.02MPa, and at the same time start the circulation heating system to heat the waste oil to 60-70 0 At C, the mixed water components in the waste oil start to distill and vacuum dehydrate; then nitrogen is filled into different parts of the distilled waste mineral oil: Nitrogen is filled into the waste oil to make the oil stir and tumbling, and the additives are continuously mixed Mixing and reaction, decolorization and deodorization of regenerated oil; Nitrogen filling in the upper space of waste oil liquid can remove space miscellaneous gas, prevent light oil components from oxidizing and igniting, and prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com