Multi-phase polypropylene copolymer having high ethylene-propylene rubber content and preparation method thereof

A technology of heterophasic polypropylene and rubber content, applied in the field of high-performance modification of polypropylene, to achieve the effect of high transparency, improved affinity, and improved softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

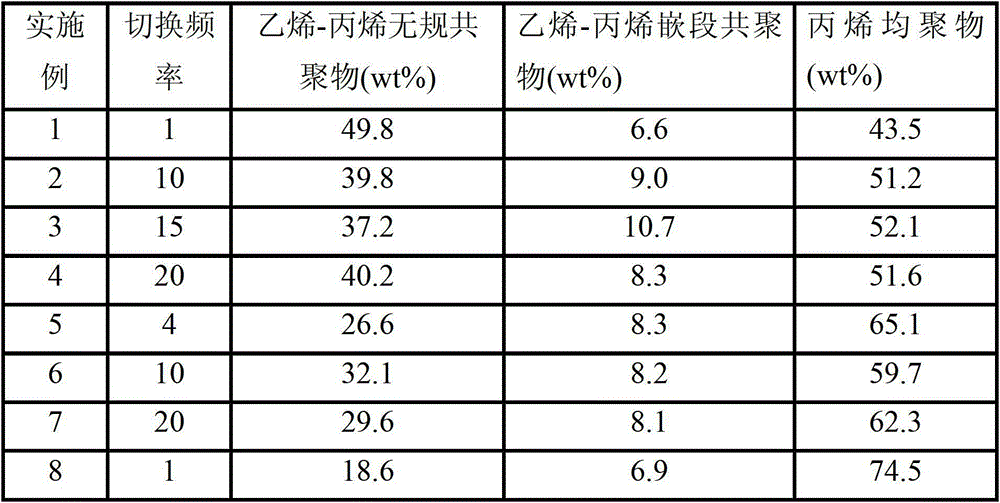

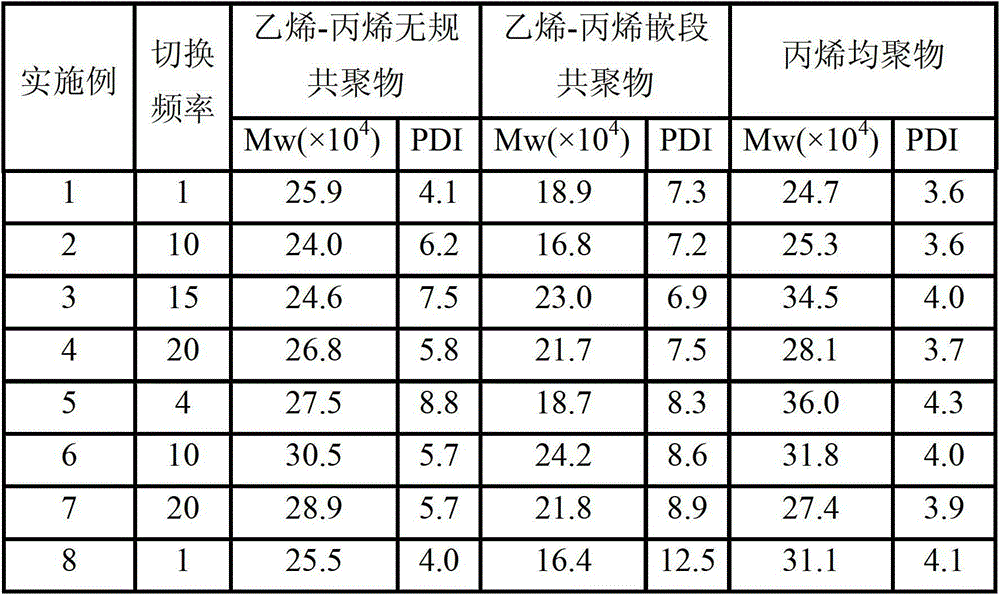

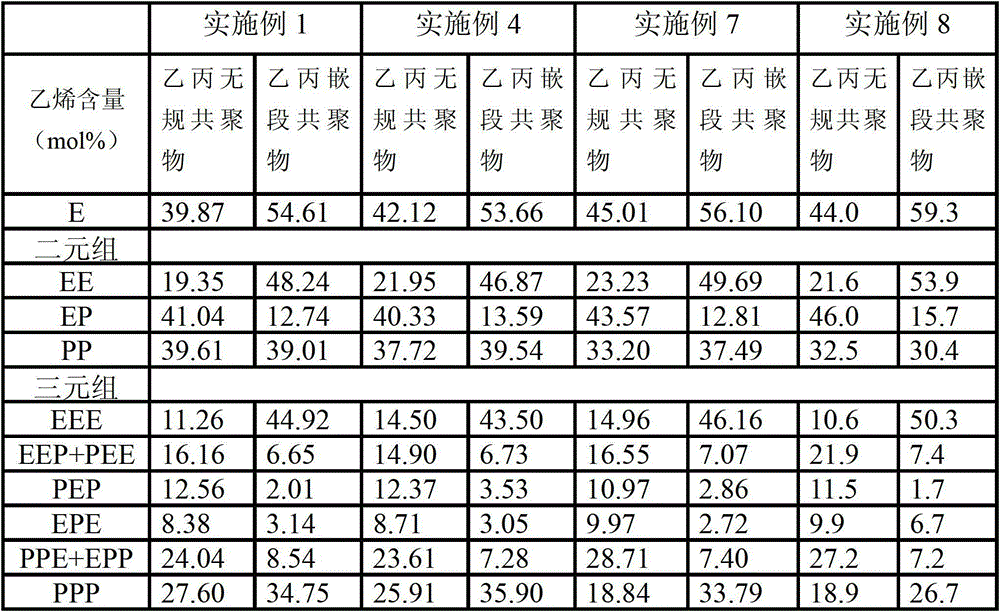

Examples

preparation example Construction

[0028] Preparation of propylene homopolymer:

[0029] (1) Propylene prepolymerization

[0030] Before the experiment, the reactor was replaced with nitrogen at least three times, and vacuum-dried at 100 °C for 2 h, and then filled with propylene gas to make the pressure slightly higher than normal pressure, while the temperature dropped to 20 °C. Add n-heptane successively, cocatalyst Al(C 2 h 5 ) 3 , external electron donor Cp 2 Si(OCH 3 ) 2 , and 0.05g of the main catalyst. The molar ratio of aluminum in the cocatalyst to titanium in the main catalyst is 100, and the molar ratio of the external electron donor to titanium is 5. The main components of the main catalyst are: TiCl 4 , MgCl 2 , and diisobutyl phthalate, are spherical particles with a particle size of 20-150 microns. Its titanium content is 2.5~3.5wt%. The reaction conditions for the prepolymerization are: pressure 0.1 MPa, temperature 20° C., and time 20 minutes. The product of propylene prepolymeriza...

Embodiment 1

[0035] Propylene prepolymerization and propylene homopolymerization are carried out in the same preparation method as propylene homopolymer.

[0036] After the homopolymerization of propylene was terminated for 0.5 hours, the pressure in the reactor was reduced to -0.09 MPa (gauge pressure), and the solvent was extracted under reduced pressure and maintained for 10 minutes. Set the homopolymerization time of propylene to 20 minutes and the copolymerization time of ethylene-propylene to 60 minutes through the control device, and set the homopolymerization of propylene first. Open the inlet valve at the bottom of the tank, and the gas phase polymerization begins: firstly, the homopolymerization of propylene is carried out, and the propylene gas (the molar percentage of hydrogen is 1%) is continuously fed from the bottom of the reactor through one of the valves at the bottom of the reactor, and the unreacted monomer It is continuously discharged through the tail gas valve to keep...

Embodiment 2

[0038] Propylene prepolymerization and propylene homopolymerization are carried out in the same preparation method as propylene homopolymer.

[0039] After the homopolymerization of propylene was terminated for 0.5 hours, the pressure in the kettle was reduced to -0.09 MPa (gauge pressure), and the solvent was extracted under reduced pressure and maintained for 10 minutes. Set the homopolymerization time of propylene to 2 minutes and the copolymerization time of ethylene-propylene to 6 minutes through the control device, and set the homopolymerization of propylene first. Open the inlet valve at the bottom of the tank, and the gas phase polymerization reaction starts: firstly, the homopolymerization of propylene is carried out, and the propylene gas (the molar percentage of hydrogen is 1%) is continuously fed from the bottom of the reactor through one of the valves at the bottom of the reactor, and the unreacted single The body is continuously discharged through the tail gas va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com