Wettable polyoxin powder and its preparation method

A technology of wettable powder and polyoxin, which is applied in the field of pesticides, can solve the problems of high energy consumption, poor sterilization effect, and high production cost, and achieve the effects of increasing yield, crop safety, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

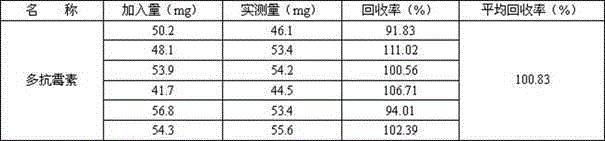

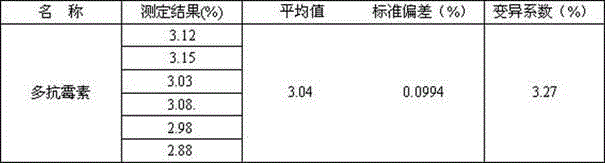

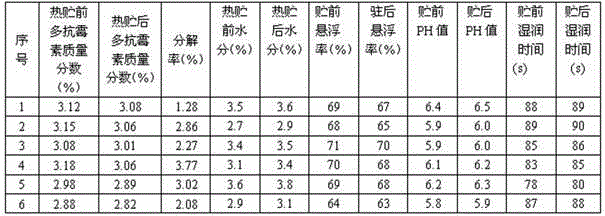

Examples

Embodiment 1

[0023] Polyoxin wettable powder is formed by mixing polyoxin, auxiliary agents and fillers. The mass percentage of polyoxin in the wettable powder is 3%, and the percentage content of auxiliary agents is 23.5%. The rest is filler.

[0024] Polyoxin is fermented from the following raw materials by weight: 0.3 parts of Streptomyces aureus, 55 parts of bran, 55 parts of soybean skin, 8 parts of rice bran, 4 parts of maltose, and 130 parts of clear water.

[0025] The composition by weight of the additives is as follows: 0.5% of organic silicon, 4.5% of pull-off powder, 18% of wetting agent, and 0.5% of coenzyme A.

[0026] The filler is composed of large, medium and trace element fertilizers, and the mass ratio of the three is 1:1:0.01.

[0027] The preparation method is as follows: first mix the bran, bean skin, maltose, rice bran, and water, and then sterilize; then mix the Streptomyces aureus strain into the fermentation tank, and control the temperature at 35°C and the humid...

Embodiment 2

[0029] Polyoxin wettable powder is formed by mixing polyoxin, auxiliary agents and fillers. The mass percentage of polyoxin in the wettable powder is 3%, and the percentage content of auxiliary agents is 23%. The rest is filler.

[0030] Polyoxin is fermented from the following raw materials in parts by weight: 0.1 parts of Streptomyces aureus, 50 parts of bran, 50 parts of soybean skin, 5 parts of rice bran, 3 parts of maltose and 100 parts of clear water.

[0031] The composition by weight of the additives is as follows: 0.5% of organic silicon, 4% of pull-off powder, 18% of wetting agent, and 0.5% of coenzyme A.

[0032] The filler is composed of large, medium and trace element fertilizers, and the mass ratio of the three is 1:1:0.01.

[0033] The preparation method is as follows: first mix the bran, bean skin, maltose, rice bran, and water, and then sterilize; then mix the Streptomyces aureus strain into the fermentation tank, and control the temperature at 30°C and the h...

Embodiment 3

[0035] Polyoxin wettable powder is formed by mixing polyoxin, auxiliary agents and fillers. The mass percentage of polyoxin in the wettable powder is 3%, and the percentage content of auxiliary agents is 24%. The rest is filler.

[0036] Polyoxin is prepared by fermenting the following raw materials in parts by weight: 0.5 part of Streptomyces aureus, 60 parts of bran, 60 parts of soybean skin, 10 parts of rice bran, 5 parts of maltose and 150 parts of clear water.

[0037] The composition by weight of the additives is as follows: 0.5% of organic silicon, 5% of pull-off powder, 18% of wetting agent, and 0.5% of coenzyme A.

[0038] The filler is composed of large, medium and trace element fertilizers, and the mass ratio of the three is 1:1:0.01.

[0039] The preparation method is as follows: first mix the bran, bean skin, maltose, rice bran, and water, and then sterilize; then mix the Streptomyces aureus strain into the fermentation tank, and ferment at a temperature of 40°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com