Iron tailing doped high-performance concrete and manufacturing method thereof

A high-performance concrete and manufacturing method technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as the shortage of natural sand resources for iron selection waste, achieve improved durability, improve integrity, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Iron-doped tailings high-performance concrete and its manufacturing method

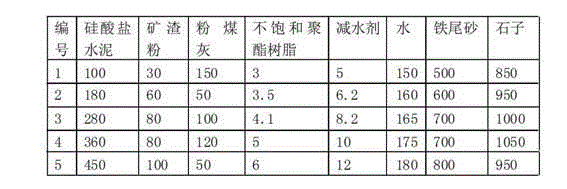

[0018] (1) High-performance concrete with iron tailings, five kinds of concrete with different ratios of raw materials, the quality of raw materials used per cubic meter of high-performance concrete with iron tailings is shown in Table 1,

[0019] Table 1 The mass of raw materials used per cubic meter of high-performance concrete mixed with iron tailings (unit: kg / m 3 )

[0020]

[0021] The Portland cement kind that present embodiment uses is ordinary Portland cement 42.5 grade; The specific surface area of slag powder is greater than 400m 2 / kg, the activity level reaches S75 or above; the specific surface area of fly ash is greater than 150m 2 / kg, grade I and II dry ash with an activity level above S75; water reducer with a water reducing rate greater than 12%; the fineness modulus of iron tailings is between 2.3 and 2.7; the fineness modulus of natural sand Between 2.5 ...

Embodiment 2

[0029] Example 2 Comparison of Cracks

[0030] According to the ratio of raw materials in Table 3 and the manufacturing method of Example 1, concrete with two ratios of raw materials was prepared. The experimental results show that, under other conditions being the same, the number of cracks over 30 mm per square meter in concrete prepared with iron tailings instead of natural sand is 6, and the number of cracks over 30 mm in length per square meter in concrete prepared with natural sand for 21 articles.

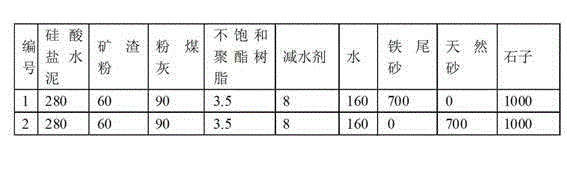

[0031] Table 3 Raw material ratio of concrete in this example (unit: kg / m 3 )

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com