Control method for planar conjugate cam contour detecting and grinding device

A plane conjugate and grinding technology, which is applied in the direction of automatic grinding control device, workpiece feed movement control, measuring device, etc., can solve the problems of easy wear of the measuring head, damage of the cam surface, high manufacturing and maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

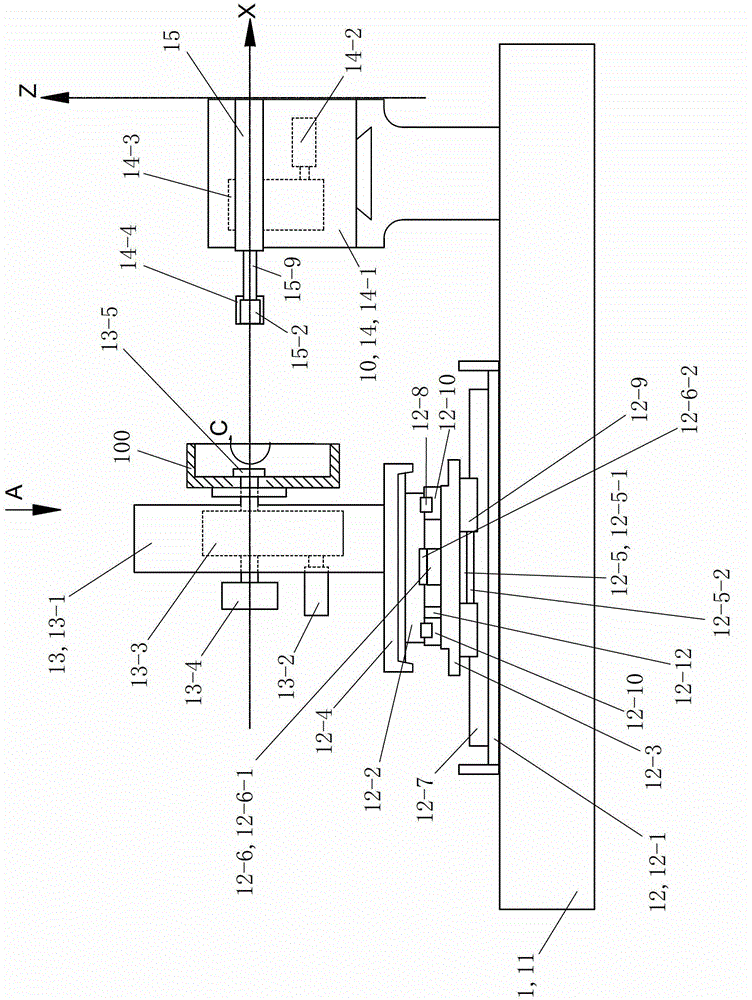

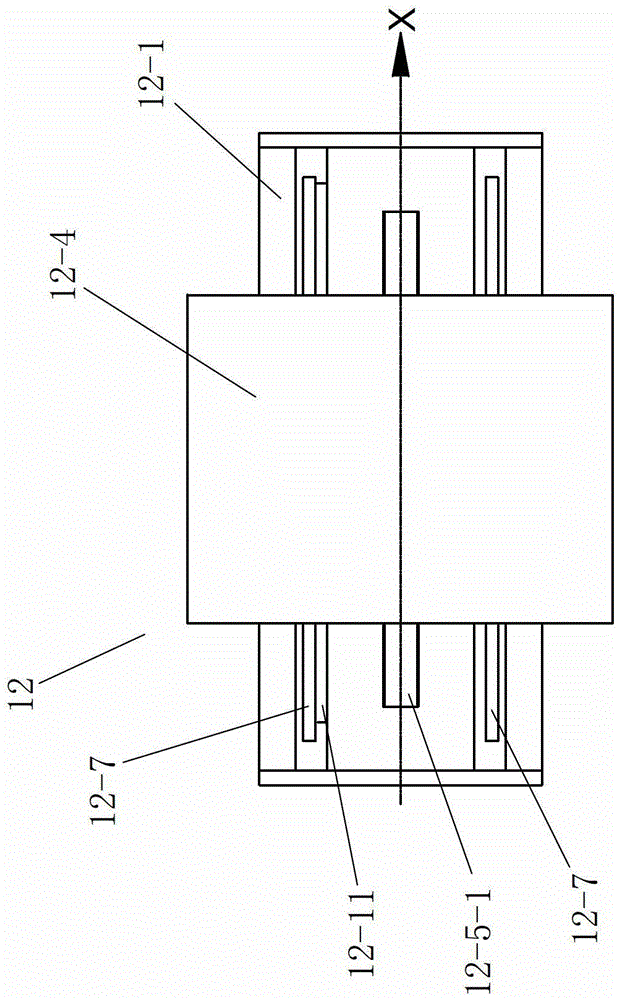

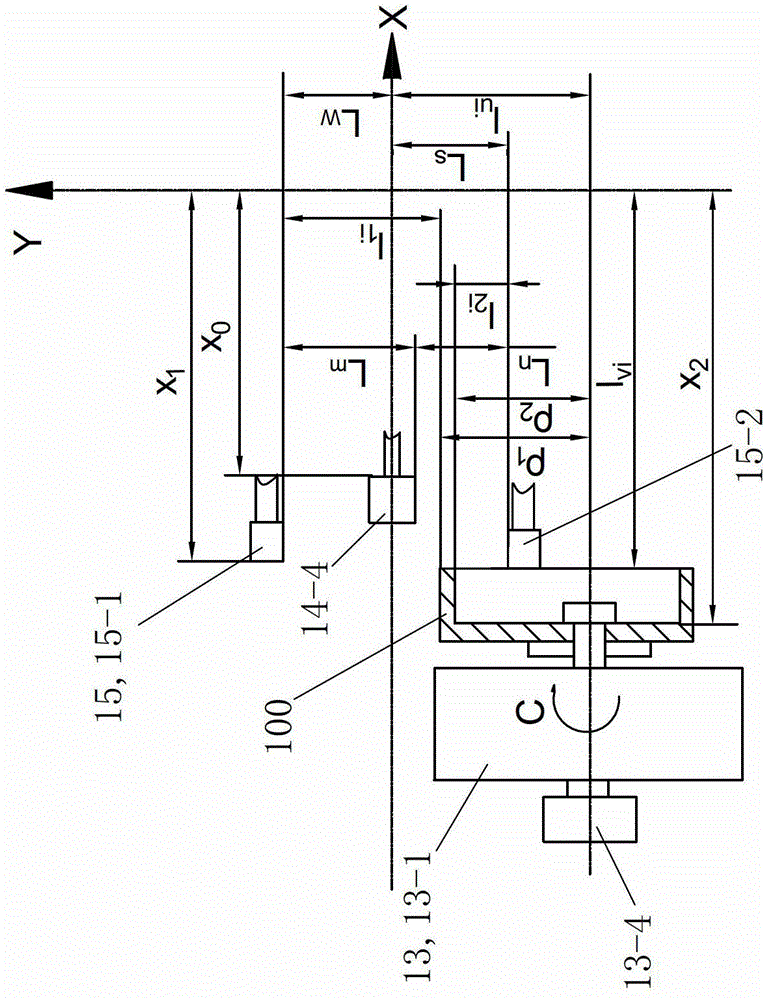

[0053] See figure 1 and figure 2 The plane conjugate cam profile detection and grinding device 1 adopted in the control method for plane conjugate cam profile detection and grinding of the present embodiment includes a control system, a detection grinding device 10, a body 11, and a moving table mechanism 12 And cam rotation mechanism 13. The mobile table mechanism 12 is arranged on the fuselage 11 and can move on the X-Y plane relative to the fuselage 11. The X-Y plane is a plane with any angle with the horizontal plane (the present embodiment is a horizontal plane, that is, the angle with the horizontal plane is 0 degrees), and the movement performed is controlled by the control system. The cam rotation mechanism 13 is fixedly arranged on the table mechanism 12 and its action is controlled by the control system. The detection grinding device 10 is fixedly arranged on the machine body 11 and its action is controlled by the control system.

[0054] See figure 1 and figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com