An EUV Lithography Illumination System Based on Freeform Surface Diaphragm Compound Eye

A technology of extreme ultraviolet lithography and aperture compound eye, which is applied in the direction of microlithography exposure equipment, optics, optical components, etc., can solve the problems of affecting the resolution of the exposure system, increasing the difficulty of designing the objective lens system, and reducing the imaging performance of the objective lens system. Achieve the effects of improving resolution, promoting industrial development, and improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

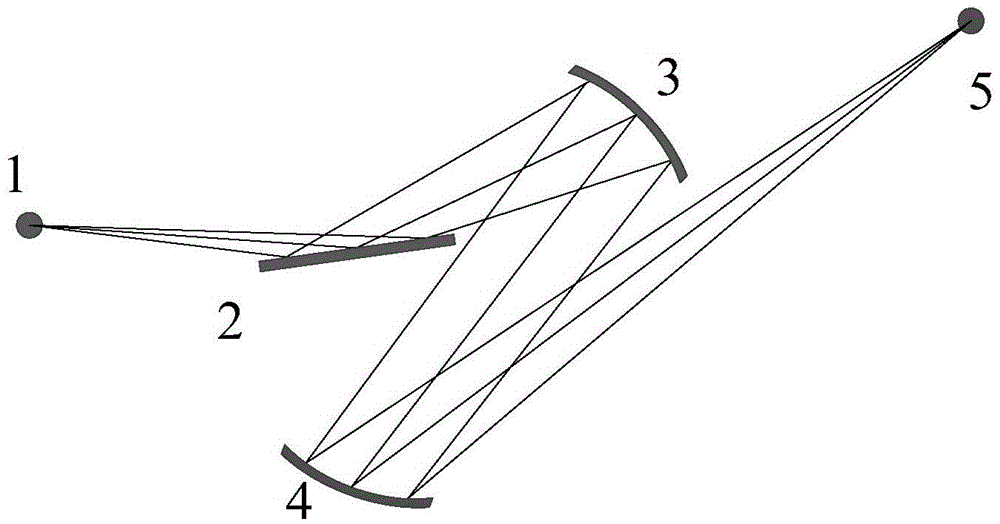

[0032] An extreme ultraviolet lithography illumination system based on a free-form diaphragm compound eye, the system includes a field of view compound eye, a diaphragm compound eye and a quadric mirror;

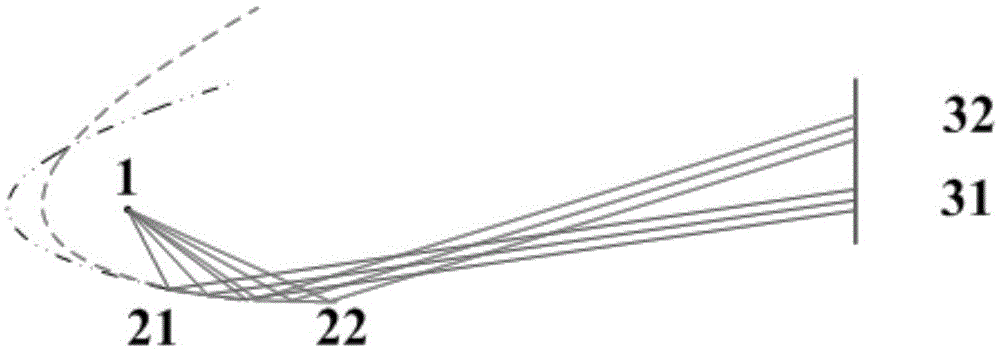

[0033] The field of view compound eye is composed of several parabolic reflectors. The reflective surface of each parabolic reflector is a rectangle. All the rectangles have the same size. All the field of view compound eyes are closely arranged on the field of view compound eye plate. After the grazing incidence reflection occurs on the compound eye of the field of view, it exits;

[0034] The diaphragm compound eye is composed of several free-form surface mirrors, the reflection surface of each free-form surface mirror is a rectangle, and all the rectangles have the same size, and all the diaphragm compound eyes are arranged on the diaphragm compound eye plate;

[0035] For the convenience of description, the present invention considers that all light beams exit from the I...

Embodiment

[0043] As shown in Table 1, the exit pupil diameter, the exit pupil distance and the size of the arc-shaped spot on the mask surface of the illumination system are determined for a given set of EUV lithography projection objective lens parameters.

[0044] Table 1

[0045] exit pupil diameter

103.7155mm

Exit pupil distance

1375.5387mm

Arc spot outer diameter

141mm

Inner diameter of arc spot

135mm

Chord length of arc spot

104mm

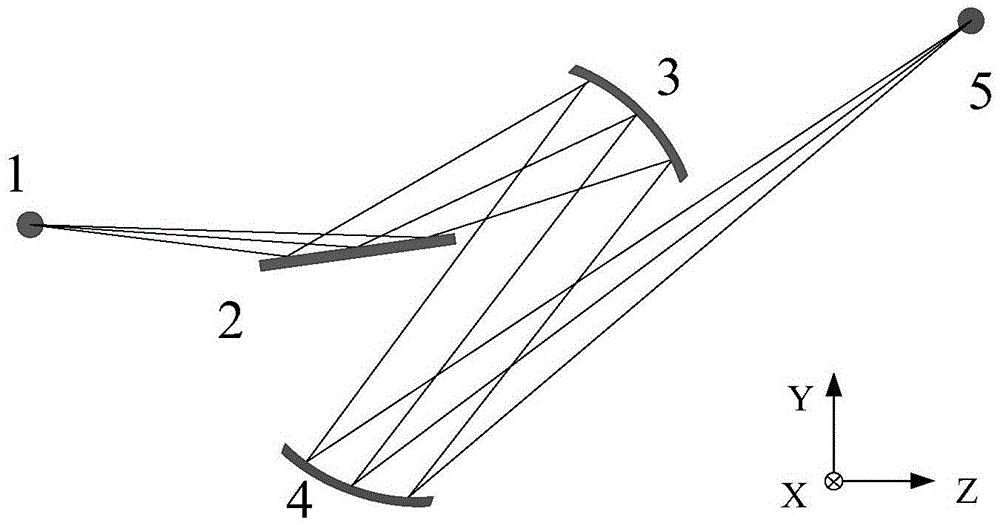

[0046] Establish a Cartesian coordinate system with the IF point as the coordinate origin, the Y axis goes up vertically, the Z axis goes horizontally to the right, and the X axis is determined according to the right-handed coordinate system, such as image 3 shown. The definition of the tilt angle of the component is as follows: the rotation angle of the component around the X axis in the Y-Z plane is defined as alpha, the rotation angle of the component around the Y axis in the X-Z plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com