Hair grinding machine

A pulverizer and hair technology, applied in grain processing, etc., can solve the problems of large space occupation, low work efficiency, and inability to crush wool to nano-scale powder, etc., to achieve the effect of small space occupation and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

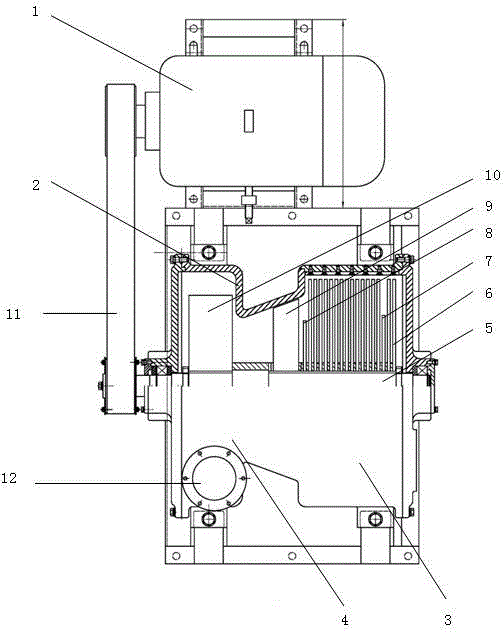

[0026] refer to figure 1 , The preferred embodiment of the present invention provides a hair shredder, which integrates the opening, crushing and grading of hair materials, and can efficiently and continuously crush hair such as wool into nano-scale powder at one time.

[0027] The technical solution adopted in the present invention is: a hair shredder, including a driving motor 1, a fixed base and a body 2, a crushing chamber 3 is provided in the body 2, and a grading chamber 4 is also provided, and the crushing chamber 3 is provided with The pulverizing device comprises a beating blade 6 connected to the transmission shaft 5, a material pushing blade 7, an air uniform blade 8 and a scraper assembly 9, one end of the side of the pulverizing chamber 3 is provided with a feed port, and one end of the discharge port is connected to the classifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com