Controlled release pellet preparation and its preparation method

A technology of sustained-release pellets and sustained-release layers, which can be used in pharmaceutical formulations, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc. problem, to achieve the effects of good release uniformity, good drug release, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

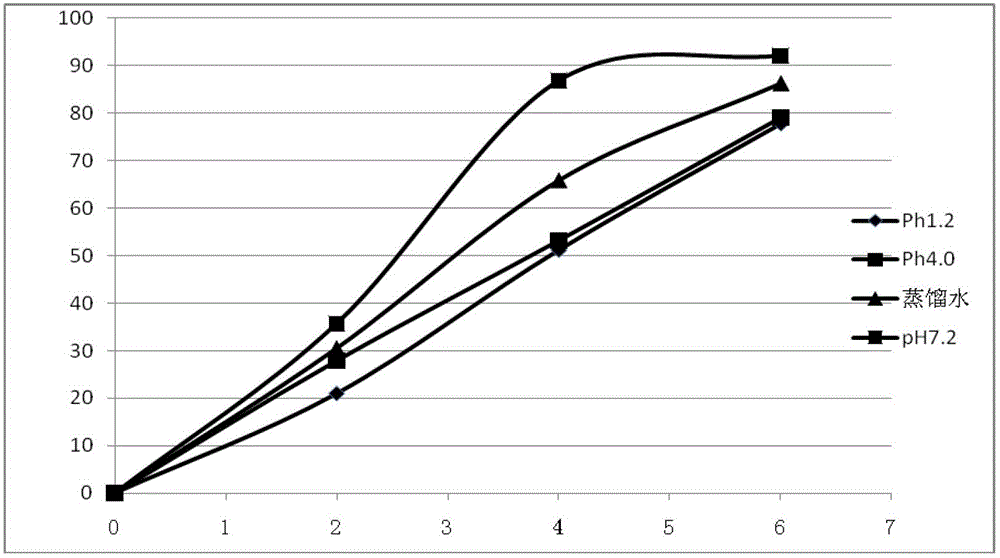

Image

Examples

Embodiment 1

[0134] Tamsulosin Hydrochloride Sustained Release Capsules (5000 capsules)

[0135] 1) Sucrose core 605g

[0136] 2) Drug-loaded slow-release layer

[0137] Tamsulosin Hydrochloride 1g

[0138] Cellulose acetate 33.75g

[0139] Tween 80 7.5g

[0140] 3) Coating layer

[0141] Udrake L100-55 11.25g

[0142] Sodium Lauryl Sulfate 7.5g

[0143] Weigh the prescribed amount of 2) each component in the drug-loaded sustained-release layer, and dissolve it in about 600 g of 95% ethanol solution to prepare the drug solution.

[0144] Weigh 3) each component of the coating layer and about 500 g of purified water, and prepare the coating liquid with the above auxiliary materials.

[0145] Put the blank pellet core in the fluidized bed, control the temperature of the material at 30-35°C, adjust the fluidized state, apply the medicine for about 2 hours, dry for 10 minutes after the medicine is applied, take out the upper pill and sieve, the mesh size of the sieve is 18-30 mesh, tak...

Embodiment 2

[0148] Tamsulosin Hydrochloride Sustained Release Capsules (5000 capsules)

[0149] 1) Sucrose core 505g

[0150] 2) Drug-loaded slow-release layer

[0151]

[0152] 3) Coating layer

[0153]

[0154]

[0155] Preparation

[0156] Step 1: Weigh each component according to the formula, dissolve each component of the drug-loaded sustained-release layer in about 500g of 95% ethanol to prepare a drug solution, apply the drug in a fluidized bed, and control the temperature of the material at 30-55°C to prepare on the pill.

[0157] Step 2: Sieve the upper pills with a mesh number of 15-30 mesh.

[0158] Step 3: Take about 550g of ethanol to dissolve the components of the coating layer; place the sieved upper pills in a fluidized bed, control the temperature of the material at 45-55°C, and continue drying for 15 minutes after the coating is completed.

[0159] Step 4: Add about 1 / 2 the amount of talcum powder to 3 times the amount of water, spray it in after homogenizi...

Embodiment 3

[0162] Tamsulosin Hydrochloride Sustained Release Capsules (5000 capsules)

[0163] 1) Sucrose core 660g

[0164] 2) Drug-loaded slow-release layer

[0165] Tamsulosin Hydrochloride 10g

[0166] Sodium Alginate 300g

[0167] 3) Coating layer

[0168] Udrake L100-55 10g

[0169] TEC 5g

[0170] 4) Micropowder silica gel 4g

[0172] Preparation

[0173] Step 1: Weigh each component according to the formula, dissolve each component of the drug-loaded slow-release layer in about 300g ethanol to prepare a drug solution, apply the drug in a fluidized bed, and control the temperature of the material at 40-45°C to prepare the drug solution. pill.

[0174] Step 2: Add micropowder silica gel to twice the amount of water, spray it in after homogenizing with a high-speed homogenizer for 5 minutes, dry it for 5 minutes, and take it out.

[0175] Step 3: Sieve the upper pills with a mesh number of 15-30 mesh.

[0176] Step 4: Take about 100g of ethanol to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com