Straw-mulching stubble-cleaning ditching seeding machine

A seeder and straw technology, applied in the direction of digging/covering ditches, harvesters, planting methods, etc., can solve problems such as malnutrition, soil condition deterioration, and uneven density, so as to increase soil organic matter content and reduce moisture Evaporation, the effect of reducing government subsidies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

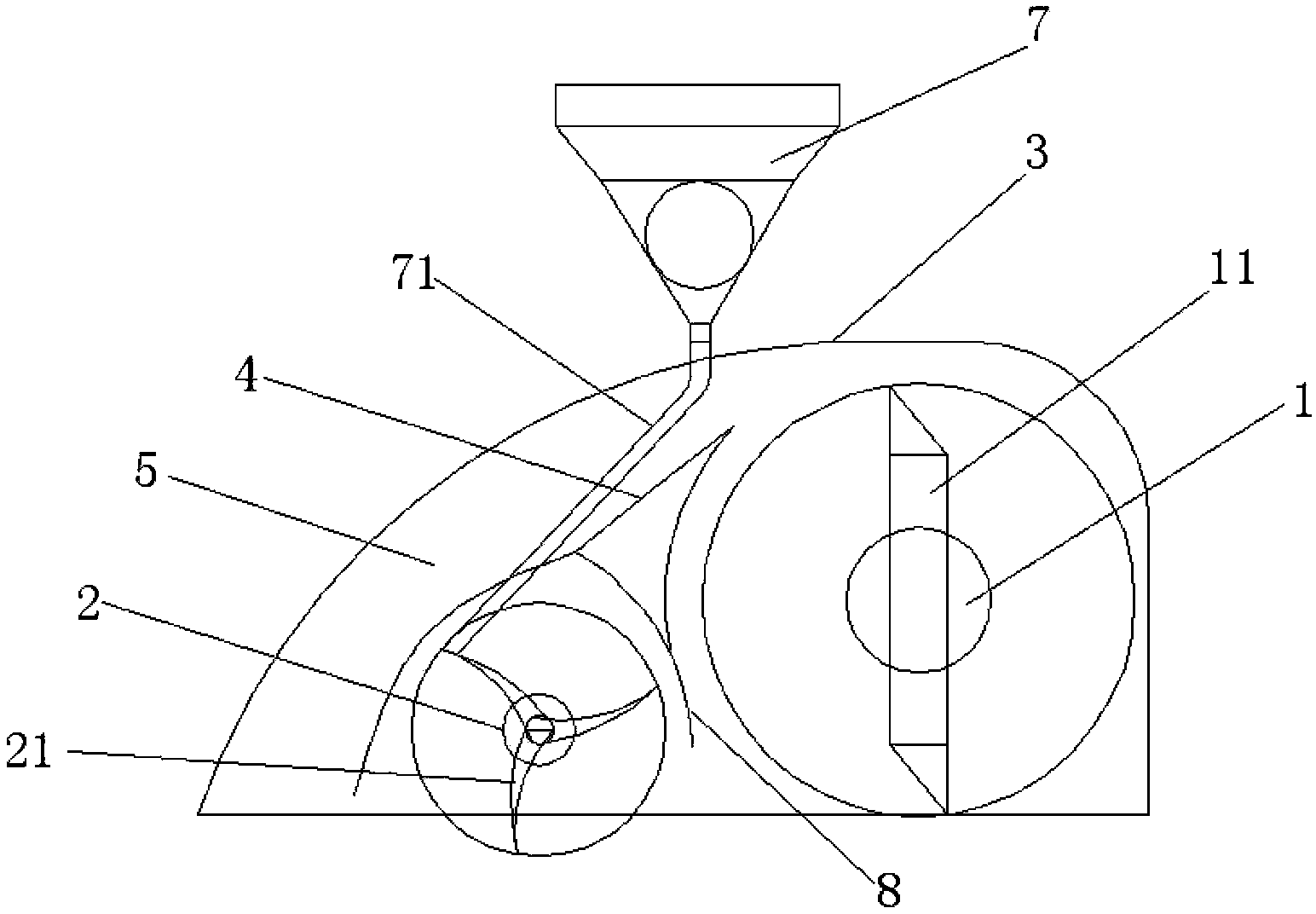

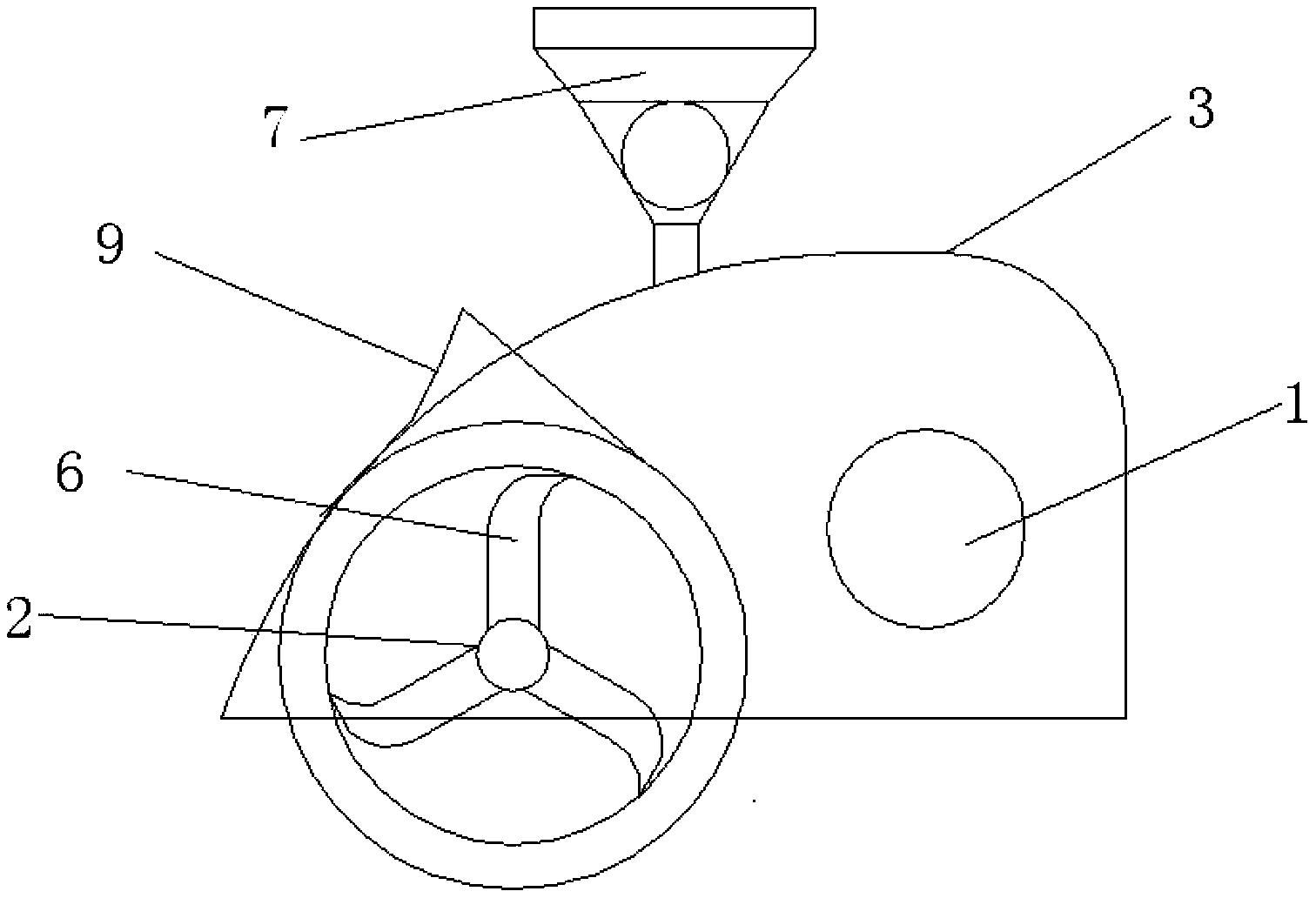

[0025] Such as figure 1 and figure 2 As shown, a straw-covered stubble removal ditching planter, based on the direction of use, includes a first roller 1 and a second roller 2 arranged front and back, and the first roller and the second roller are arranged above the second roller. There is a casing baffle 3, a diverter plate 4 is arranged between the second roller and the casing baffle, and a crushed straw flow channel 5 is formed between the splitter plate and the casing baffle; The first roller is provided with a first knife-roller group, and the first knife-roller group can pick up and pulverize the straw on the surface so that it enters the crushed straw flow channel; the second roller is provided with a second knife The rolling group and several ditching knives 6, the second knives rolling group can remove stubble and chop the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com