Polymer based double compressible layer carcass for printing blanket

A compression layer, blanket technology, applied in the direction of blanket covering, printing, rubber layered products, etc., can solve the problems of low compressibility, high load value of blanket, unsuitable application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

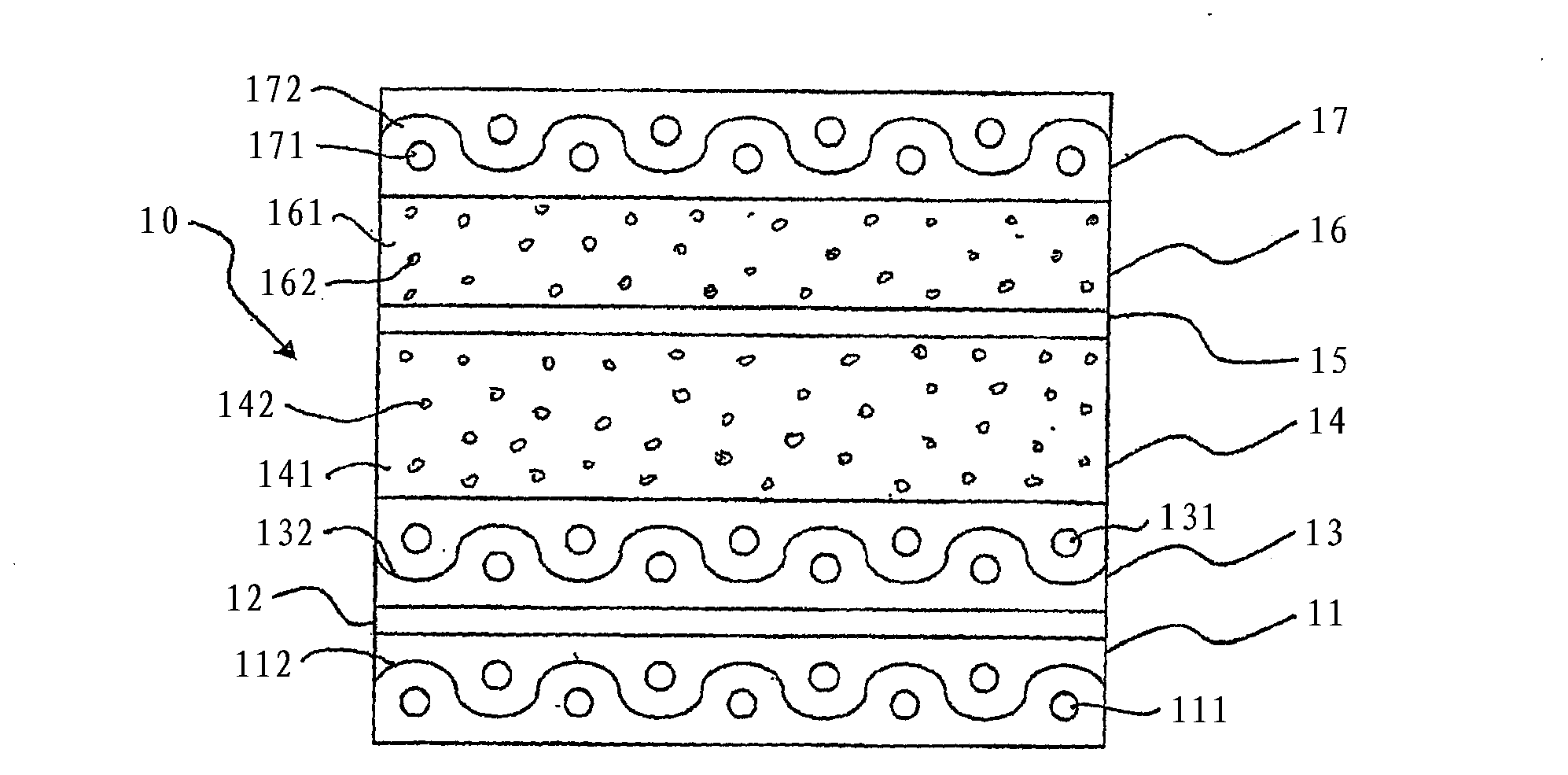

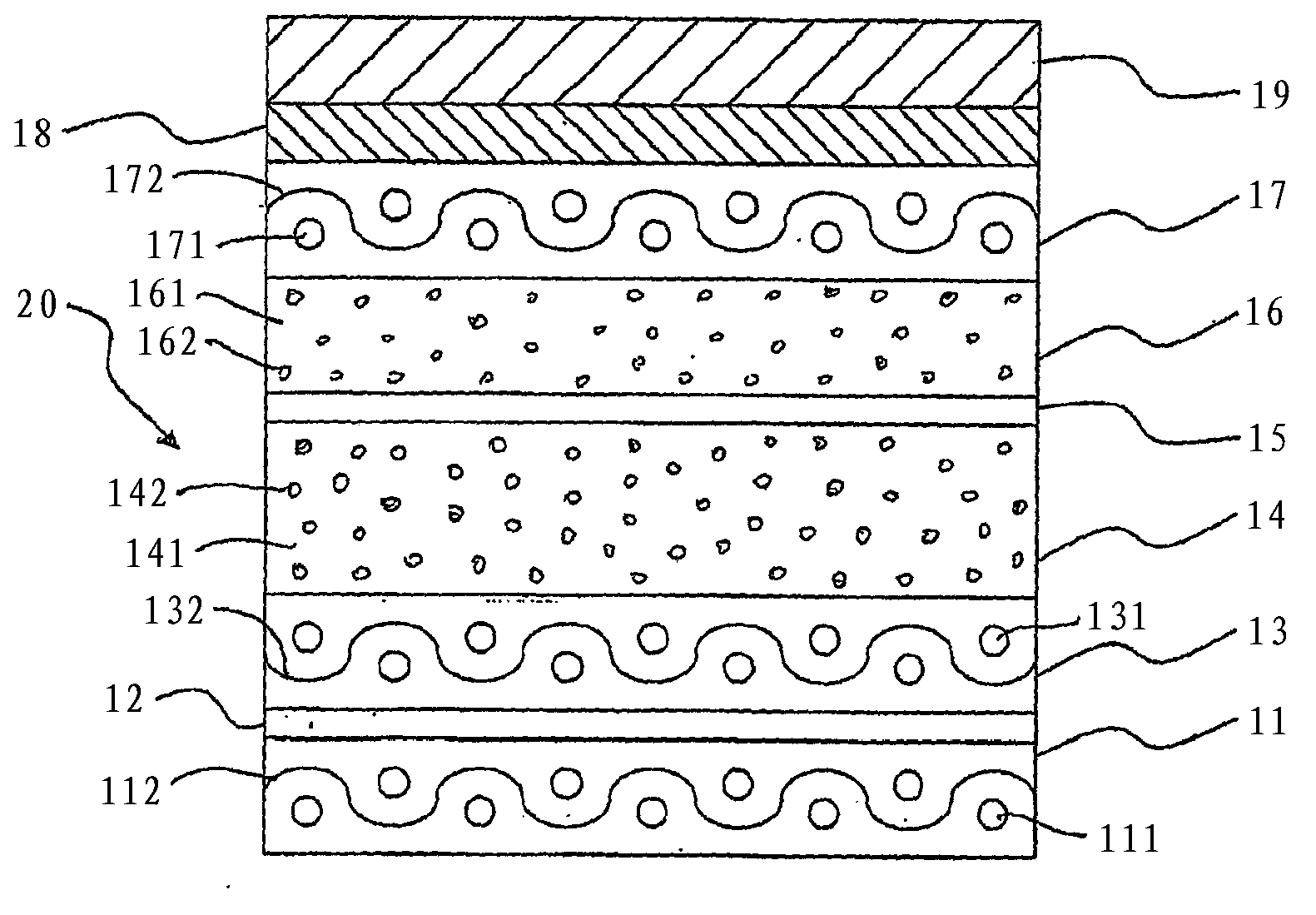

[0022] figure 1 A first embodiment of a carcass 10 of the present invention for a printing blanket is shown. The frame includes, in order, a first fabric layer 11 forming a base layer, an adhesive layer 12, a second fabric layer 13, a first compressible layer 14, a spacer layer 15, a second compressible layer 16, and a third fabric layer 17.

[0023] Typically, fabric layers used in the present invention may have a fiber or yarn count per inch in the warp and weft directions of about 8 to 60 counts per centimeter, depending on the denier of the fibers or yarns. (20-150 counts / inch). In addition, the fabric weight is in the range of 65 to 270 grams per square meter, preferably about 135 to 270 grams per square meter (2 to 8 ounces per square yard, preferably 4 to 8 ounces per square yard) and the thickness is between 0.125 to 0.75 millimeters (0.005 to 0.03 inches), can be used for specific applications of the various fabric layers of the present invention.

[0024] The text...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com