Control system used for ball grid array (BGA) repair platform

A control system and rework station technology, applied in electrical program control, program control in sequence/logic controller, printed circuit manufacturing, etc., can solve the problem of inaccurate matching of BGA chip pins and PCB pads, and operation Not simple and intuitive enough, temperature control is not accurate enough, etc., to achieve the effect of not simple and intuitive operation, simple structure, convenient and intuitive operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

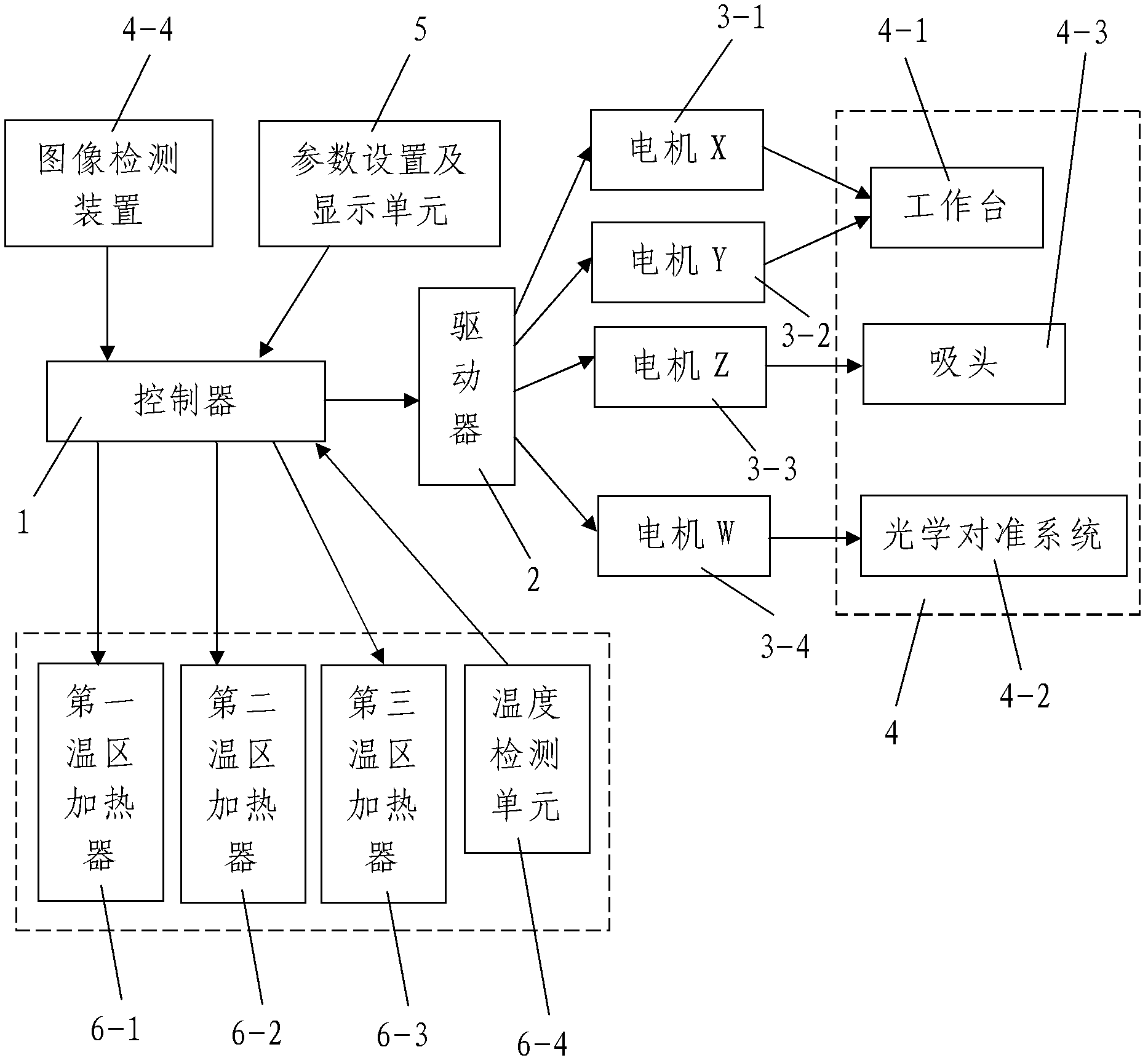

[0026] Such as figure 1 As shown, the present invention includes a controller 1, a motor driven by a driver 2, a controlled device 4 driven by the motor, a parameter setting and display unit 5, an image detection device 4-4, and a first temperature zone heater 6-1, the temperature monitoring system 6 composed of the second temperature zone heater 6-2, the third temperature zone heater 6-3 and the temperature detection unit 6-4. The number of the motors is 4 and the 4 motors are respectively motor X3-1, motor Y3-2, motor Z3-3 and motor W3-4, and the controlled device 4 includes motor X3-1 and motor W3-4 respectively. The workbench 4-1 that is connected to the motor Y3-2, the optical alignment system 4-2 that is connected to the motor W3-4, and the suction head 4-3 that is connected to the motor Z3-3, The number of the image detection devices 4-4 is two, and the two image detection devices 4-4 are respectively installed on the workbench 4-1 and the suction head 4-3. The driver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com