A fast and precise measurement method for distributed plane six-degree-of-freedom pose

A precision measurement and degree of freedom technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of low integration, high cost, complex structure, etc., and achieve the effect of reducing motion load, easy operation, and simple adjustment of optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

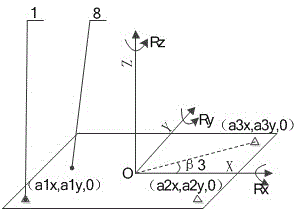

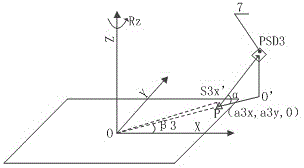

[0021] The structural diagram of the distributed planar six-degree-of-freedom rapid and precise measurement device of this embodiment is as follows: figure 1 As shown, the measurement device includes a corner cube prism 1 arranged on the platform to be tested 6, a light source assembly and a signal receiving assembly arranged on a measurement frame 11 which remains stationary during the measurement process, a signal acquisition and operation circuit board 9 and a main control Computer 10; described corner cube prism 1 and light source assembly and signal receiving assembly are 3 sets, and every set of light source assembly and signal receiving assembly are all fixed on the measuring frame 1l by mechanical mount 2; Described light source assembly includes being installed on Collimating lens 3 and laser diode 4 in light source box 5;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com