Tunnel type heat drying chamber

A drying room and tunnel-type technology, applied in the field of tunnel-type drying rooms, can solve problems such as difficulty in fitting the drying room, and achieve the effects of high work efficiency, satisfying drying treatment, and strong drying treatment capability.

Inactive Publication Date: 2013-06-05

NANTONG JINXU METAL PROD

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, in the processing and manufacturing of agricultural and sideline products, drying rooms are more and more widely used, and the requirements for drying agricultural and sideline products are relatively high, so it is difficult for traditional drying rooms to be suitable

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

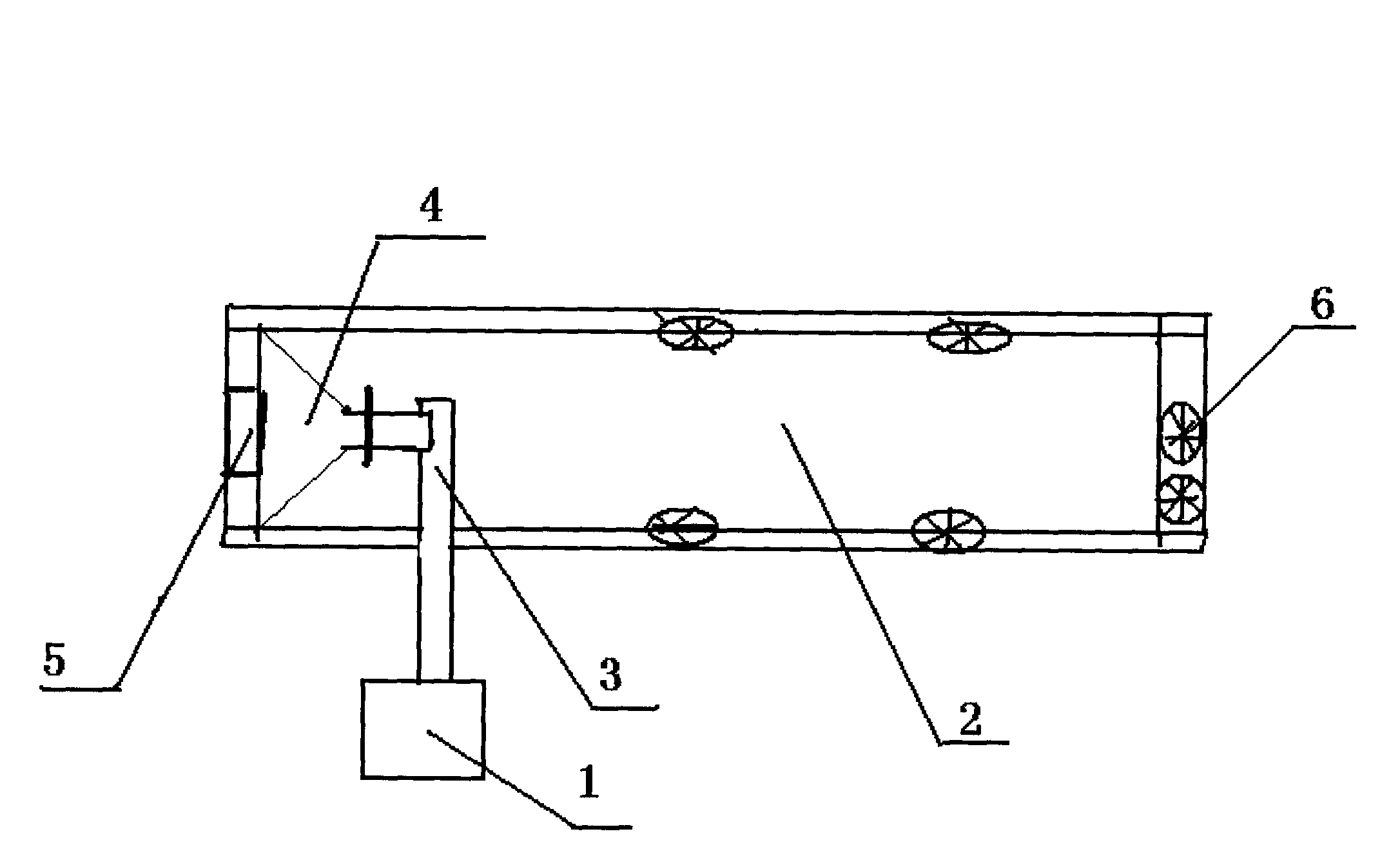

[0009] A tunnel-type drying room, comprising a fan 1 and a tunnel-type drying room 2, characterized in that: the hot air duct 3 of the fan 1 is connected to the tunnel-type drying room 2 and enters the tunnel-type drying room 2, the air outlet 4 of the hot air duct 3 is provided with an air equalizer 5, and a plurality of exhaust fans 6 are provided on the surrounding walls of the tunnel type drying room 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A tunnel type heat drying chamber comprises a fan and a tunnel type heat drying chamber body, wherein a warm air pipe of the fan is connected with the tunnel type heat drying chamber body and enters into the tunnel type heat drying chamber body, an air equaling device is arranged on an air outlet of the warm air pipe, and a plurality of moisture removal fans are arranged on the peripheral walls inside the tunnel type heat drying chamber body. The tunnel type heat drying chamber has strong drying processing capacity, can meet requirements for drying of agricultural and sideline products, and is high in working efficiency.

Description

technical field [0001] The invention relates to the field of dryers, in particular to a tunnel-type drying room. Background technique [0002] At present, in the processing and manufacturing of agricultural and sideline products, drying rooms are more and more widely used, and the requirements for drying agricultural and sideline products are relatively high, so it is difficult for traditional drying rooms to be suitable. Contents of the invention [0003] In order to overcome the defects in the prior art, the present invention provides a tunnel-type drying room with strong drying processing capacity. [0004] For realizing above technical purpose, the present invention will adopt following technical scheme: [0005] A tunnel-type drying room, comprising a fan and a tunnel-type drying room, the hot air duct of the fan is connected to the tunnel-type drying room and enters the tunnel-type drying room, the air outlet of the hot-air duct At the place, an air equalizer is ar...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F26B15/00F26B3/02

Inventor 马祝琪

Owner NANTONG JINXU METAL PROD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com