A vacuum drying system for capacitor voltage divider for transformer

A capacitive voltage divider and vacuum drying technology, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of high energy consumption, large dispersion of drying effect, long processing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

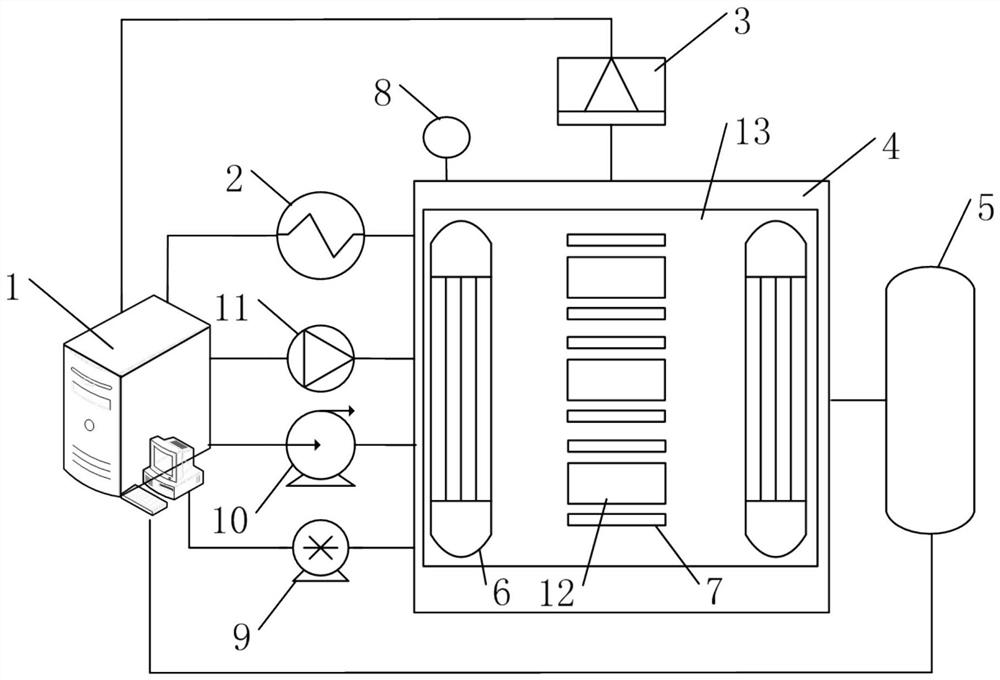

[0067] The invention provides a vacuum drying system for a capacitive voltage divider for a transformer, such as figure 1 As shown, it includes: a controller 1, a dehumidifier 3, a drying device 4, a heating mechanism, a drying position 12 and a vacuuming device;

[0068] The inside of the drying device 4 is provided with a drying space 13; the heating mechanism, the dehumidifier 3, and the vacuum device are respectively connected with the drying space 13 of the drying device; A capacitive voltage divider; a vent valve is provided between the dehumidifier 3 and the drying space 13; the drying space 13 of the drying device 4 is provided with a temperature sensor 7 for sensing the temperature of the drying space 13 and a pressure sensor 8 for sensing the pressure of the drying space 13 The vacuum device is used to vacuumize the drying space 13 of the drying device 4; the heating mechanism is used to heat the drying space 13 of the drying device 4, and the dehumidifier 3 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com