Adjustable type cable fixed support

A fixed bracket and adjustable technology, applied in the direction of pipeline brackets, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of cables that cannot be adjusted, inconvenient to adjust, and inconvenient to use, and achieves convenient transportation, processing, and expansion. The effect of adjusting the range and expanding the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

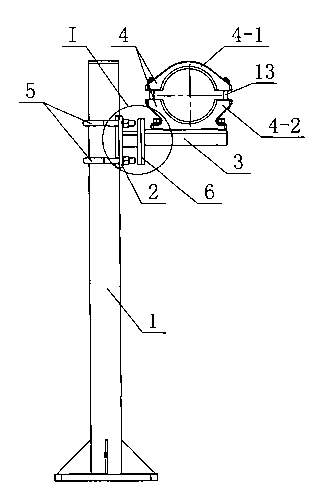

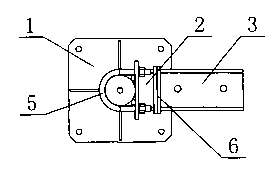

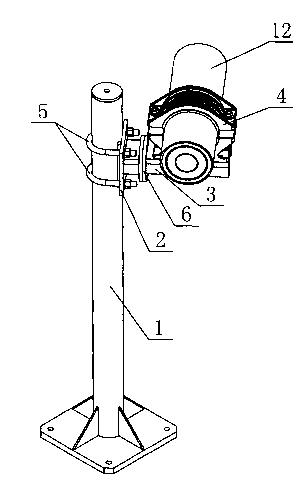

[0034] Such as Figure 1-7 As shown, an adjustable cable fixing bracket includes a column 1 , a cantilever 3 , a mount C2 and a U-bolt 5 . The mounting seat C2 is fixedly connected to the cantilever 3 , and the mounting seat C2 and the column 1 are connected by U-shaped bolts 5 .

[0035] Since the mounting base C is connected to the column through U-shaped bolts, the cantilever connected to the mounting base C can move up and down along the column during installation. In addition, the cantilever connected to the mounting base C can be installed horizontally around the column. Column and cantilever split structure, convenient for transportation and processing.

[0036] In order to enable the cantilever to rotate around the mount C, a swivel seat 6 is provided between the mount C2 and the cantilever 3, one side of the swivel seat 6 is fixedly connected to the mount C2 through a connector 7, and the other side of the swivel seat 6 is fixed to the cantilever 3. catch.

[0037...

Embodiment 2

[0044] Such as Figure 1-7 As shown, an adjustable cable fixing bracket, this embodiment is basically the same as Embodiment 1, the difference is:

[0045] Preferably there are still two arc-shaped grooves 11, preferably four keys 10 matched with the arc-shaped grooves 11, and two left and right keys 10-1 and two up and down keys 10-2 are selected for use. The two left and right keys 10-1 cooperate with the arc groove 11 to realize the adjustment of the cantilever rotation angle close to 360 degrees, and the two up and down keys 10-2 cooperate with the arc groove 11 to realize the adjustment of the cantilever rotation angle close to 360 degrees. adjust. Therefore two left and right keys 10-1 and two up and down keys 10-2 four keys 10 cooperate with arc groove 11, have realized the adjustment of the all-round cantilever 3 rotation of 360 degree angles. The cantilever 3 has no dead angle for rotation adjustment.

[0046] In order to improve the anti-rust and anti-corrosion ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com