Two-stage compression oil well pump and oil pump process thereof

A two-stage compression and oil pumping technology, applied in the direction of pumps, pump components, variable displacement pump components, etc., can solve the problems of shortened pump inspection cycle, no sand control groove, increased development cost, etc., and achieve good stress conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

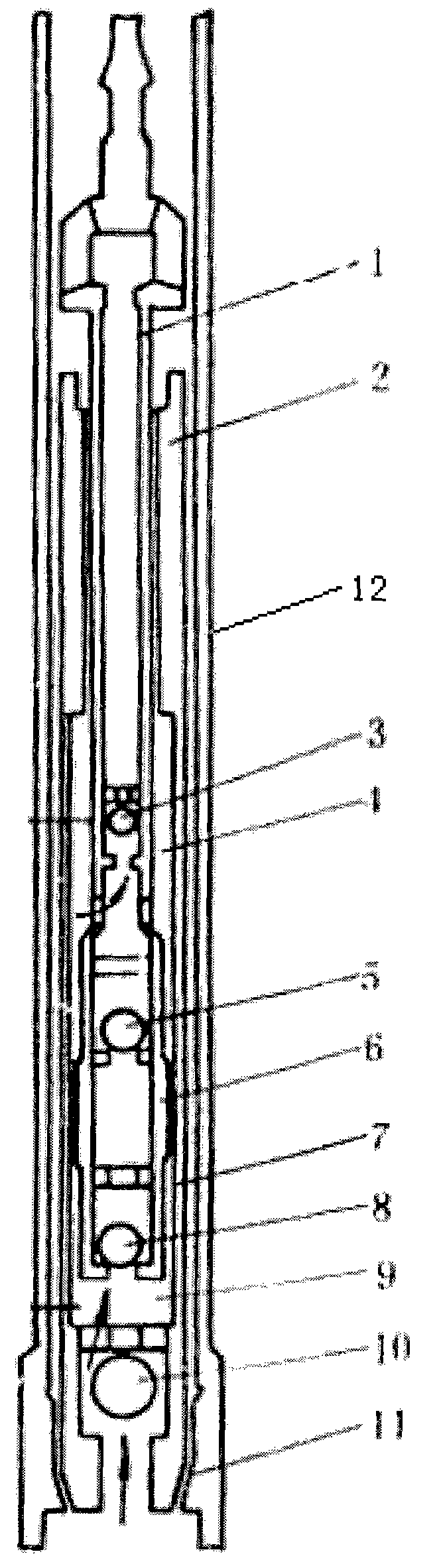

[0032] The two-stage compression oil well pump that the present invention relates to is as figure 1 As shown, it mainly consists of upper pump barrel 2 and lower pump barrel 7 communicated with each other, upper plunger 1 and upper oil outlet valve 3 arranged inside upper pump barrel 2, lower plunger 6 arranged inside lower pump barrel 7, The lower oil outlet valve 8 and the oil inlet valve 10 constitute.

[0033] The space of the upper pump cylinder 2 outside the upper plunger 1 constitutes the upper working chamber 4, and the space of the lower pump cylinder 7 outside the lower plunger 6 constitutes the lower working chamber 9, and the space between the upper working chamber 4 and the lower working chamber 9 is arranged. There is a middle oil outlet valve 5.

[0034] The middle oil outlet valve 5 is mainly composed of a middle discharge valve and a middle swimming valve.

[0035] The oil inlet valve 10 is mainly composed of a suction valve and a fixed valve.

[0036] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com